Powder/liquid mixing solutions in the Silverson Machines product range

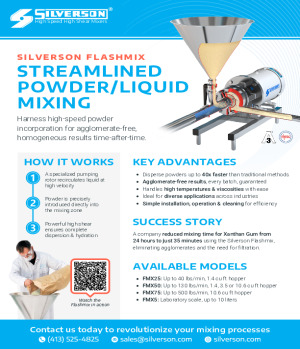

The Silverson product range now has more powder/liquid mixing solutions than ever before with the development of the FMX5 Laboratory scale powder/liquid mixer and a version of the Flashmix which is supplied with a powder suction hose attachment.

The Silverson product range now has more powder/liquid mixing solutions than ever before with the development of the FMX5 Laboratory scale powder/liquid mixer and a version of the Flashmix which is supplied with a powder suction hose attachment.

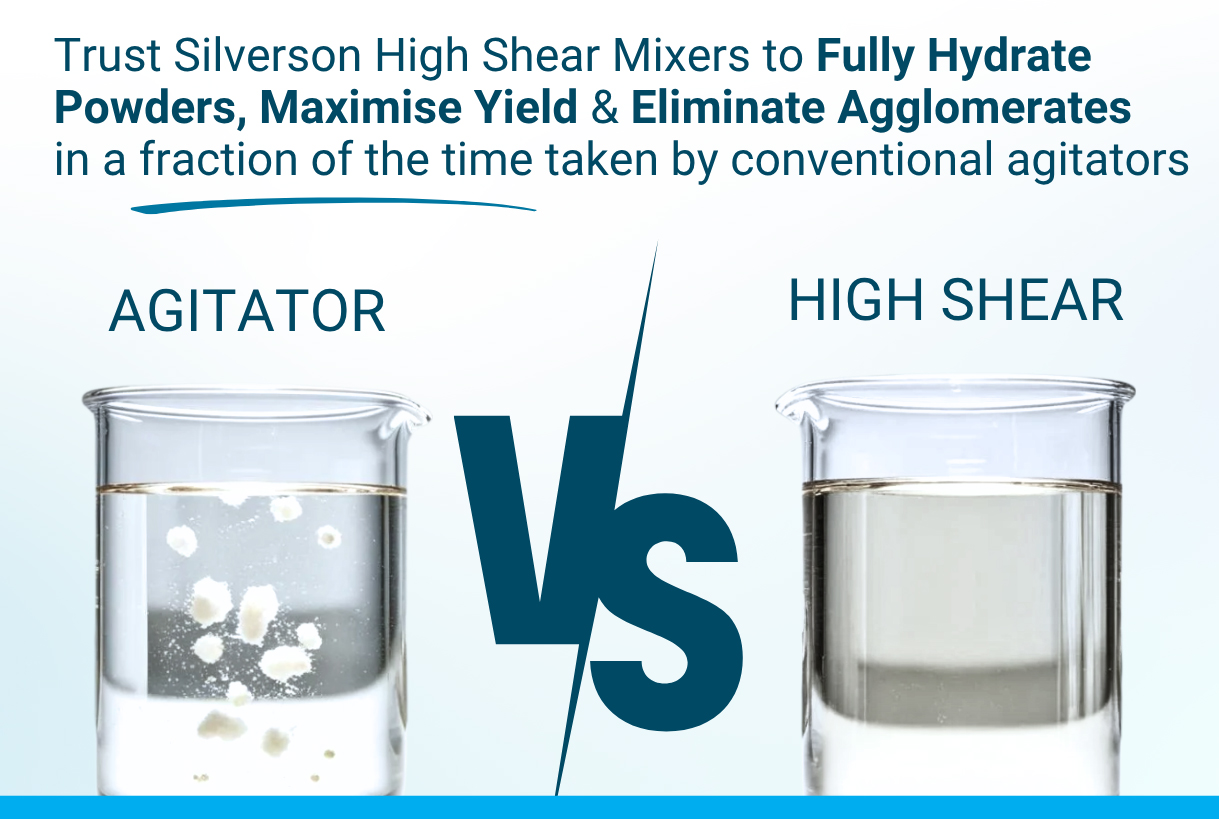

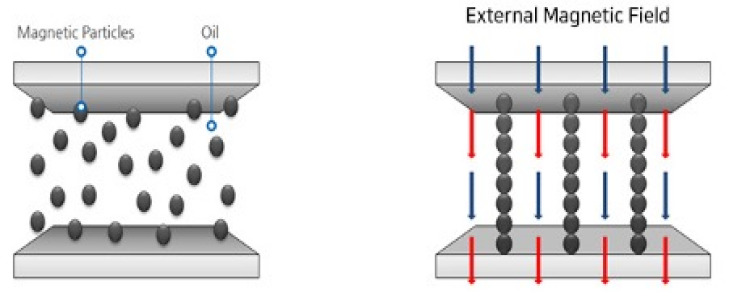

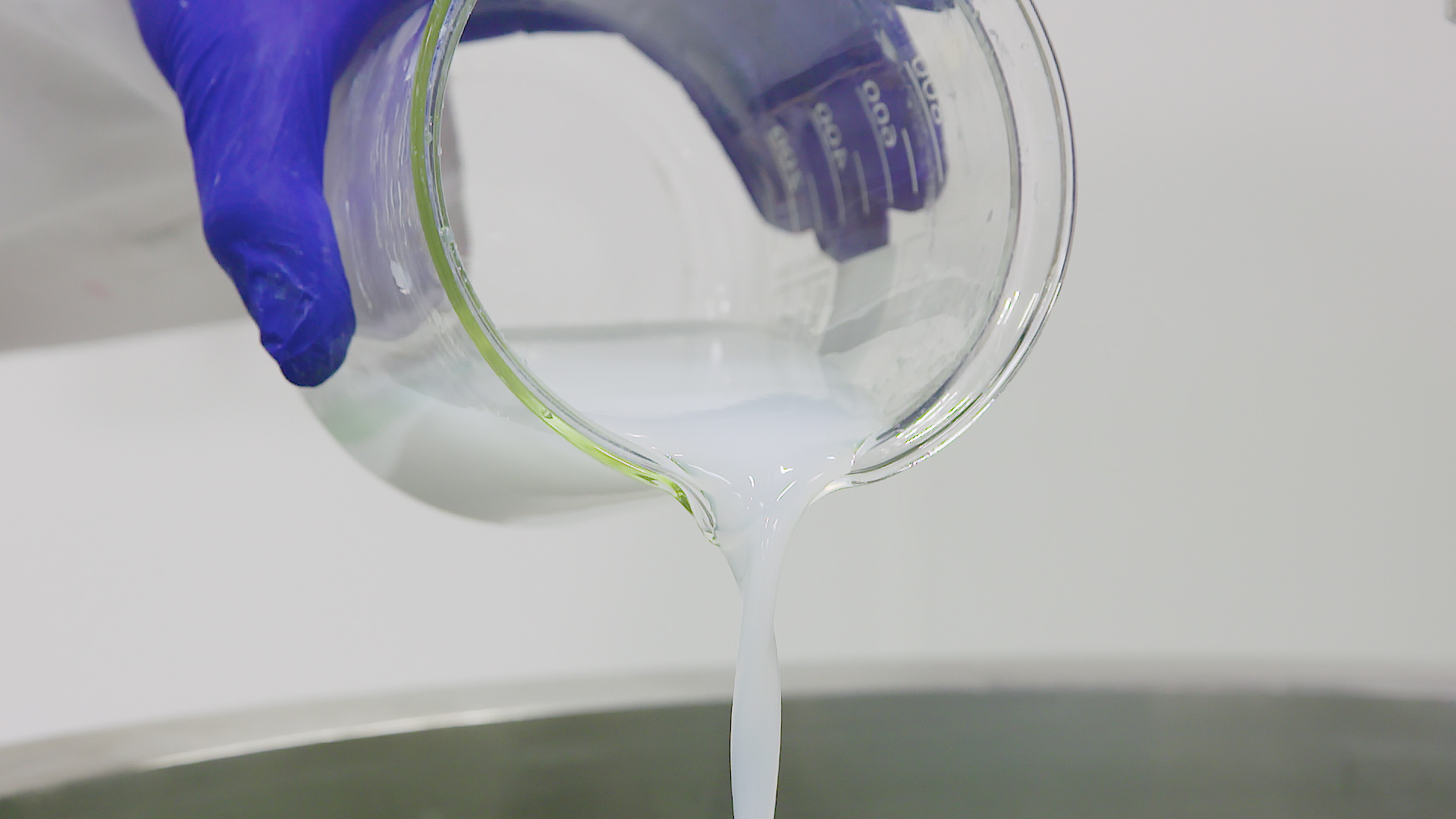

Dispersing powders into liquids and creating a consistent, homogeneous product, time after time, is one of the most difficult of all mixing tasks. Whether the need is to incorporate large volumes of powders or handle small amounts of critical components such as active ingredients, Silverson has a comprehensive range of products designed to provide the most efficient means of incorporating powders into liquids.

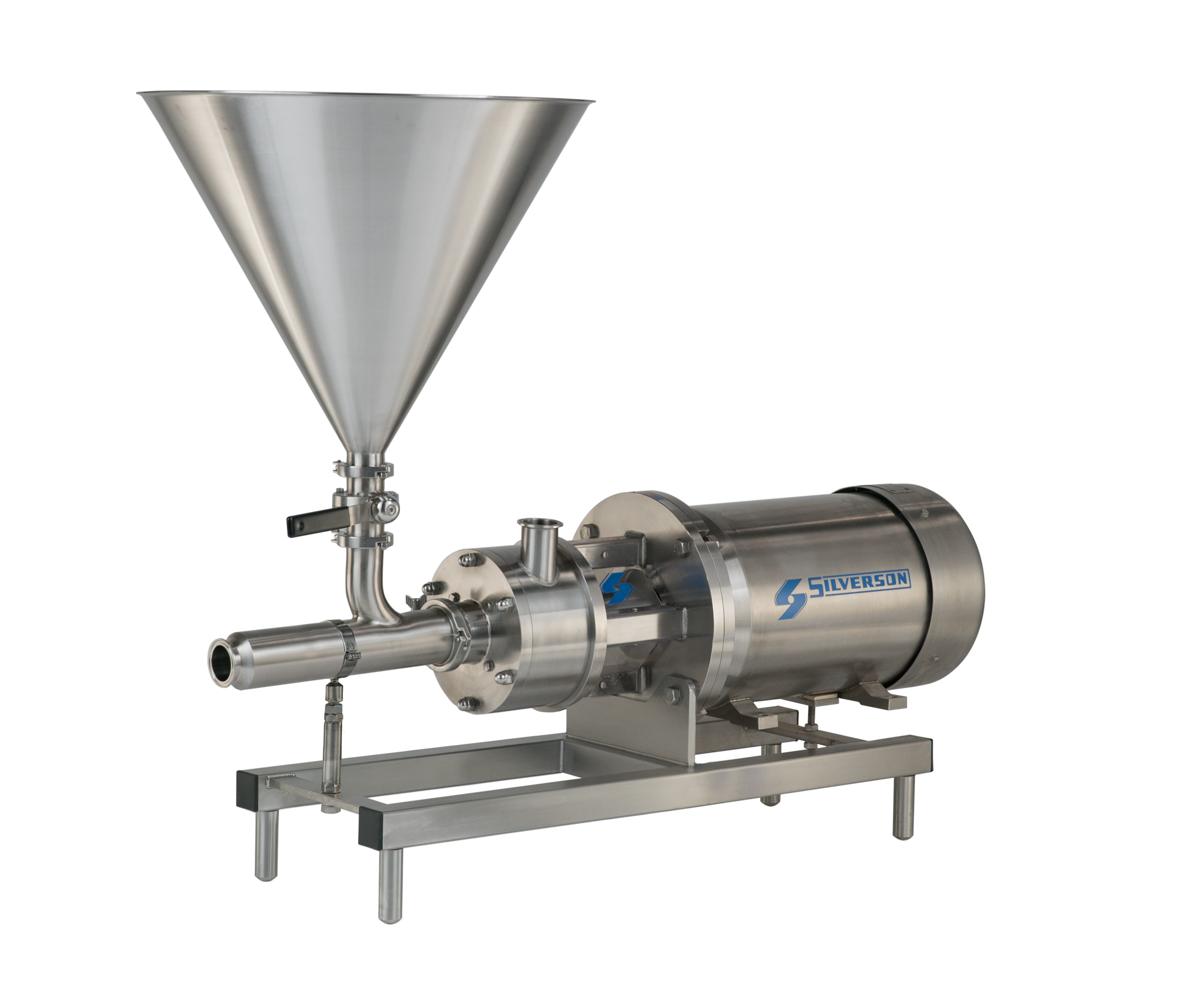

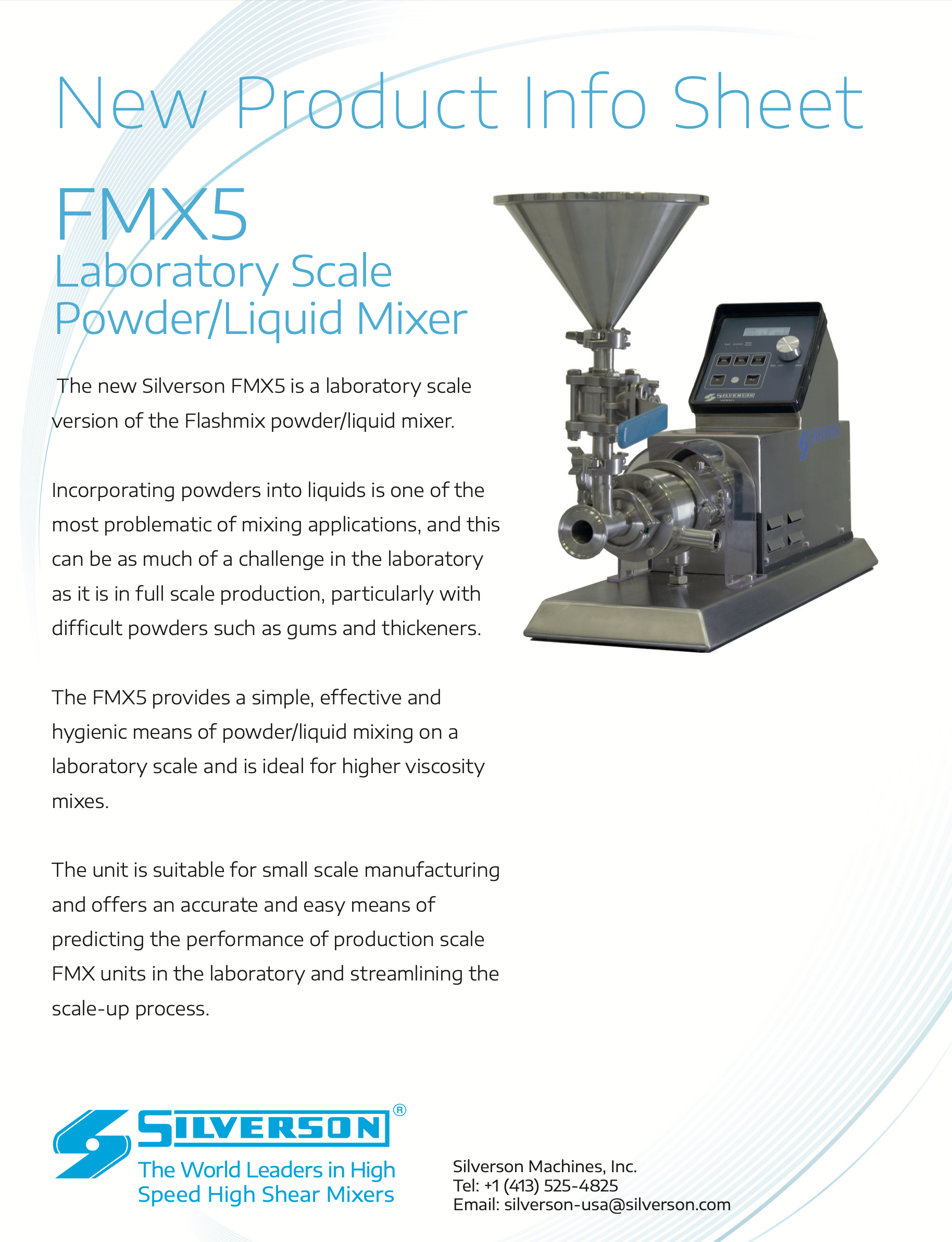

Silverson can now provide customers with the same powder/liquid mixing advantages as larger-scale production with the introduction of the FMX5 to the product range. The FMX5 is a benchtop version of Silverson's production scale Flashmix mixers and provides a simple, effective, and hygienic means of powder/liquid mixing on a Laboratory scale. It is also able to process higher viscosity mixes.

The FMX5 is suitable for small-scale manufacturing and R&D work with a typical batch size of up to 10 liters, depending on viscosity. The mixer offers an accurate means of predicting the performance of the production scale Flashmix, making the scale-up process a simple task.

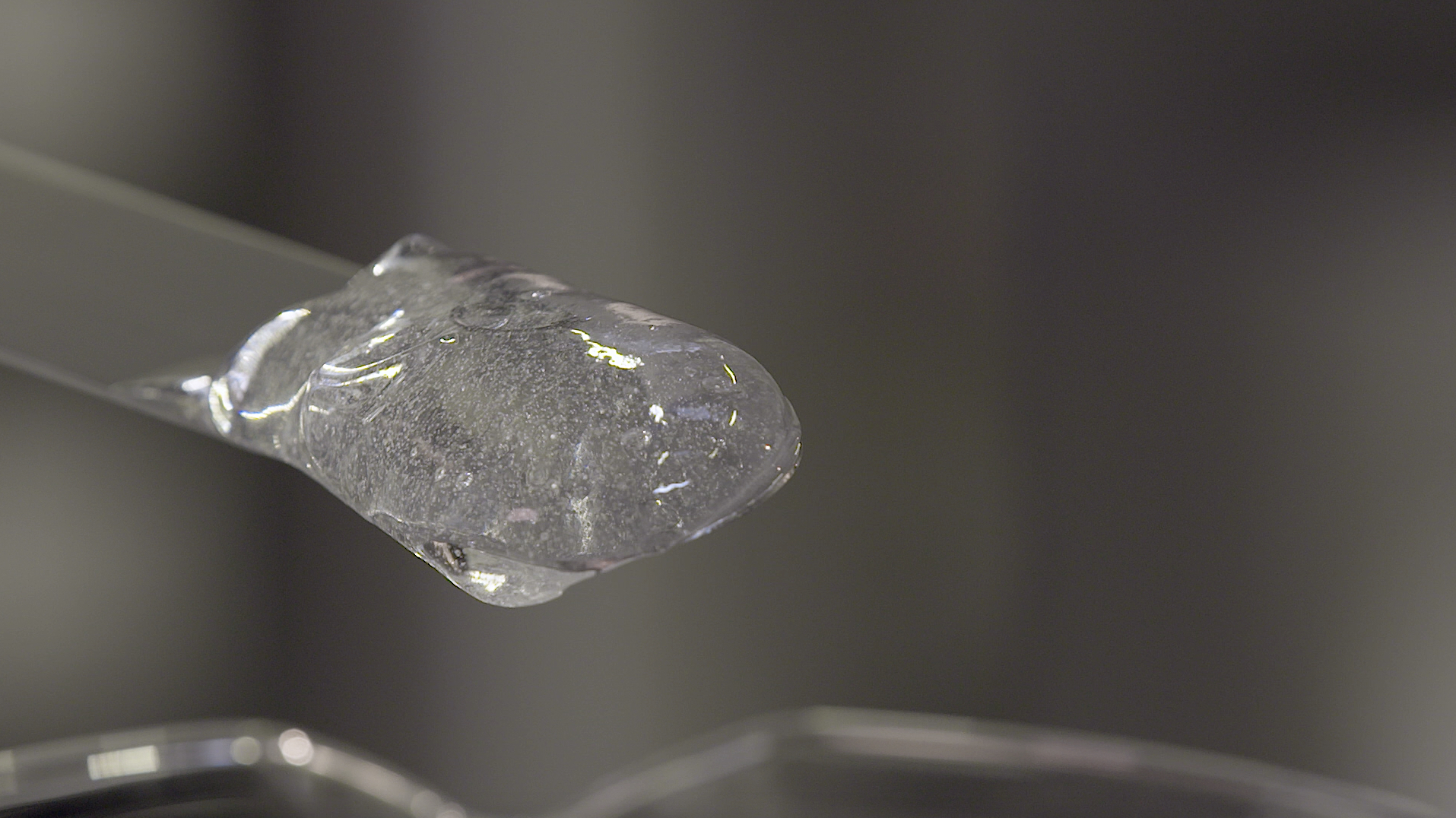

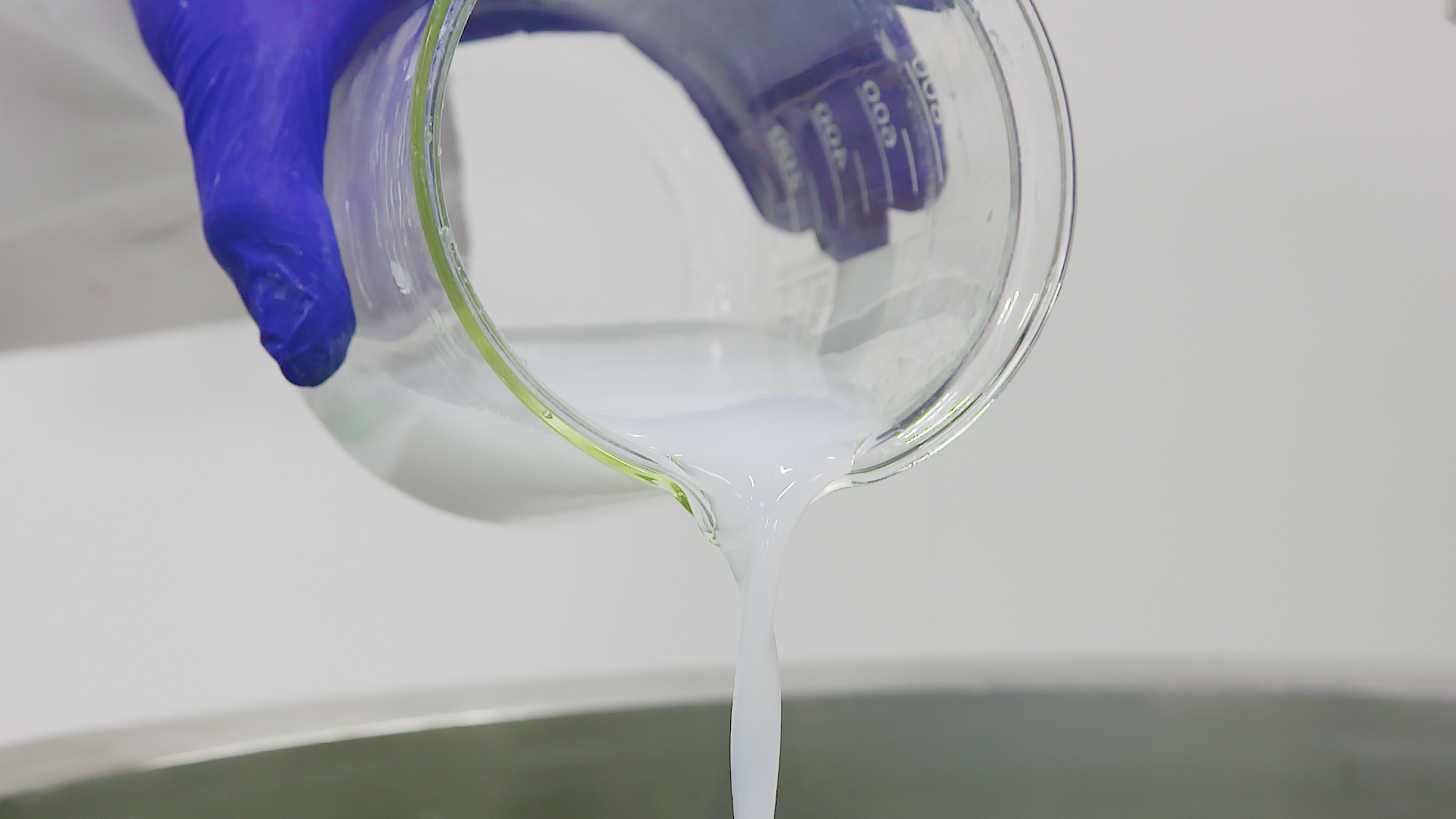

The mixer recirculates liquid from the vessel and powder is loaded into the stainless-steel hopper. Once the powder feed valve is opened the high pumping action forces the powder into the high-velocity liquid stream. The powder and liquid ingredients are introduced straight into the high shear zone of the mixer and are instantaneously combined as they are subjected to intense hydraulic and mechanical shear. A brief period of recirculation results in an agglomerate-free, homogeneous dispersion in a matter of minutes. Different designs of powder feed hoppers are available to assist with the flow of more cohesive powders.

The FMX5 offers proven performance on a wide range of powders including gums (CMC, Guar, Gum Arabic, Pectin, Xanthan), sugars, flours, milk powder, and Carbopol, Bentonite, and many others across a range of industries. The introduction of this Powder/Liquid mixer to the Silverson product range opens the possibility of many more applications than were previously possible at a laboratory scale.

The Silverson FMX5 Laboratory scale Powder/Liquid mixer

The Silverson FMX5 Laboratory scale Powder/Liquid mixer

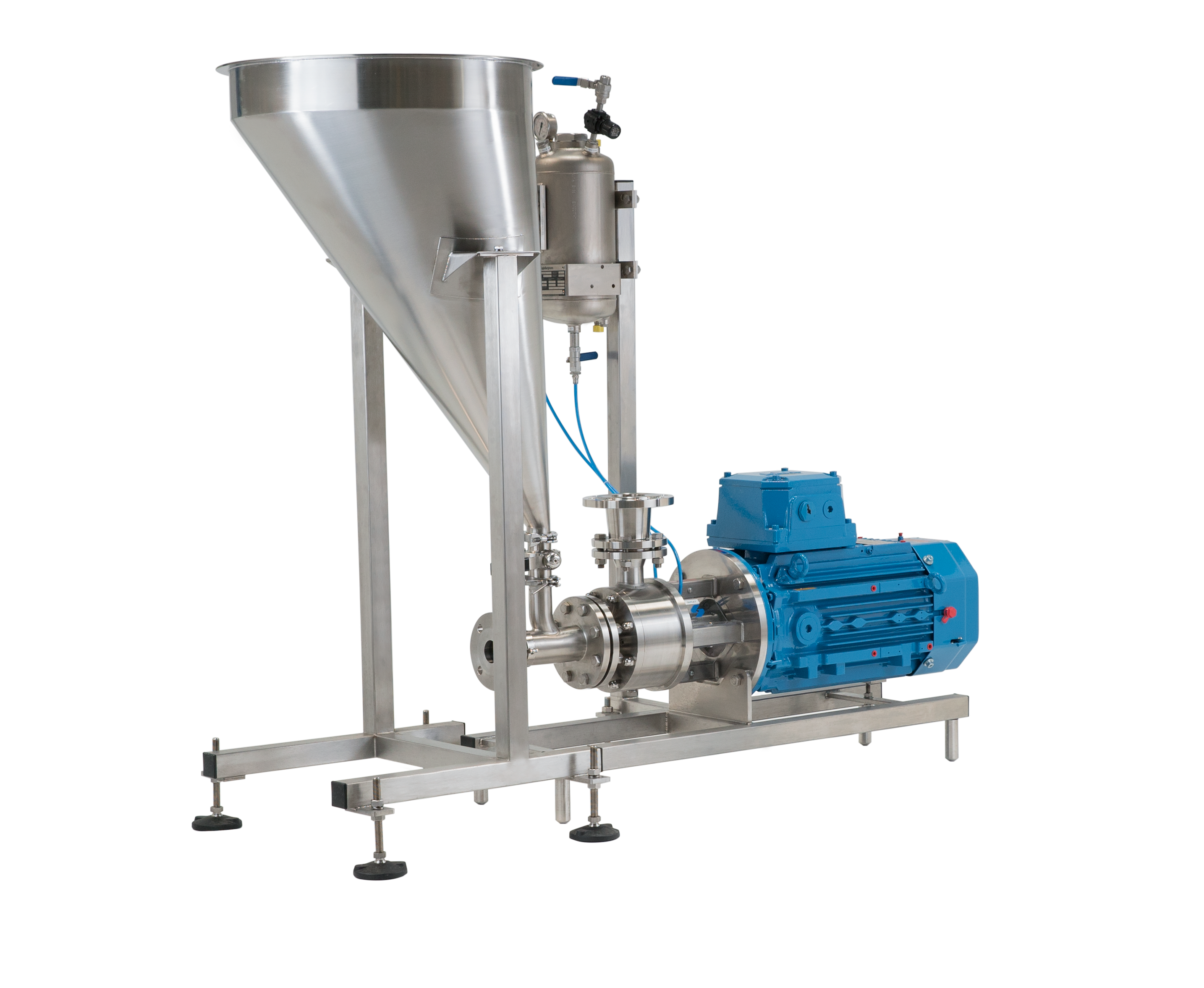

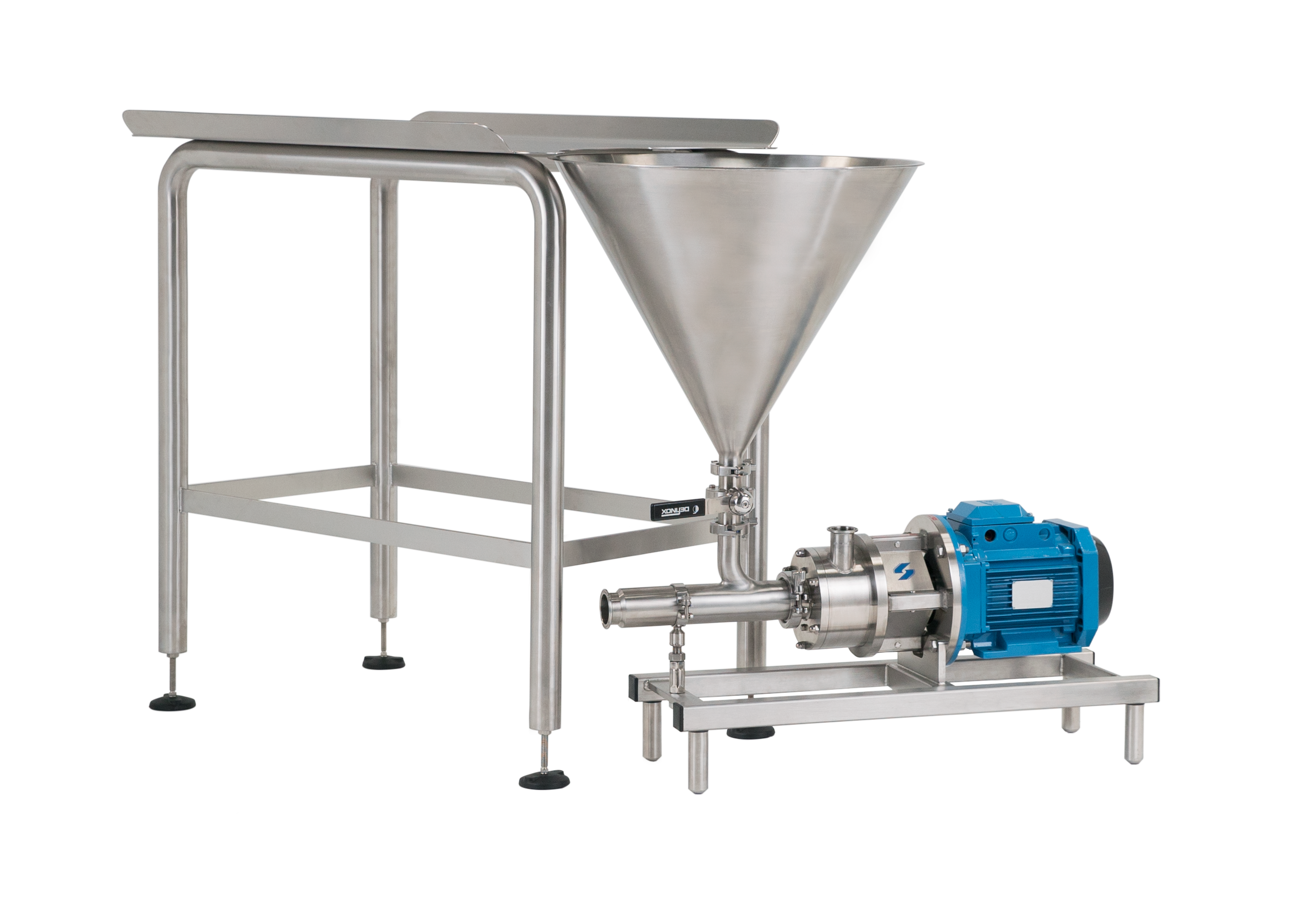

For larger scale powder dispersion, with powder incorporation rates of up to 500 lbs/min, Silverson offers the Flashmix. Unlike many other powder/liquid mixers which use a vacuum to pull in powders, the Silverson Flashmix literally forces powder into the liquid stream. This allows it to disperse ...

+ Read more

For larger scale powder dispersion, with powder incorporation rates of up to 500 lbs/min, Silverson offers the Flashmix. Unlike many other powder/liquid mixers which use a vacuum to pull in powders, the Silverson Flashmix literally forces powder into the liquid stream. This allows it to disperse and hydrate large volumes of powders before they enter the mixing vessel, preventing the build-up of partially hydrated powder on the vessel wall which can be a problem when using conventional agitators. The Flashmix can is also suitable for use at higher temperatures and with higher viscosity mixes.

The Flashmix can now be supplied with a powder suction hose attachment for powder incorporation, rather than the standard hopper. The hose is attached to the Flashmix via a specially modified powder inlet manifold that draws the powder up through the hose and into the vessel. This enables the machine to suck powders into the mix straight from their original containers, minimizing handling requirements. This is particularly useful for free-flowing powders which are prone to dusting, for example, Aerosol. Other applications include sugars, salt and gums, and thickeners such as pectin and starch.

With the use of either the standard Flashmix hopper or the hose attachment, problems occurring due to operator error, such as adding powders too quickly, can be effectively eliminated. With the Silverson Flashmix range, the mixer dictates the powder addition rate, so repeatability is assured, and a consistent homogeneous product will be produced batch after batch – both in the Laboratory and on the production floor.

For sanitary powder/liquid mixing requirements, an Ultra-Sanitary version of the FMX5 Laboratory powder/liquid mixer is available. This model offers single or double mechanical sealing arrangements and is ideally suited for applications in the pharmaceutical, biotech, food, cosmetics, and other “clean” industries.

For large-scale production, Ultra-sanitary versions of the Silverson Flashblend can also be supplied for aseptic processing and Clean Room operation. The Flashblend is designed to incorporate powders on a continuous and semi-continuous basis. It is generally configured as a semi-automatic system with a clean-in-place (CIP) mode, allowing the unit to be used for continuous operation and repeated batch production without stoppages for manual cleaning or inspection.

For in-tank powder/liquid mixing, the Silverson Ultramix can rapidly incorporate high percentages of powders and can handle relatively high viscosity mixes. It is particularly useful for incorporating difficult powders with a tendency to float or “raft.”

- Read less

Published by Silverson Machines on Nov 21, 2022