High Shear Mixers in Graphene based products and applications

In the latest video from Silverson Machines see how Silverson High Shear mixers are helping those at GEIC (Graphene Engineering Innovation Centre) with the commercialisation of graphene products.

The unique characteristics of graphene make it an appealing material for use in electronics, smart packaging, bioengineering, super capacitors and nanodevices to name but a few. However, while the commercial potential is substantial, until very recently, the processes used to obtain defect-free graphene yielded such minuscule amounts that development of this potential into commercial applications remained more a theoretical possibility than a reality.

Now that Graphene is available in large quantities, ongoing research by GEIC at the University of Manchester, UK, and other institutions, is helping companies incorporate it into formulations for a wide range of products.

What is graphene?

Dr Lisa Scullion, Applications Manager at GEIC describes it as: "Graphene is essentially the building blocks of graphite. It is a one-atom-thick layer of carbon atoms, so it has a huge surface area. As such, graphene is exceedingly strong, highly conductive, very elastic and creates an almost perfect barrier which lets nothing through, not even gases."

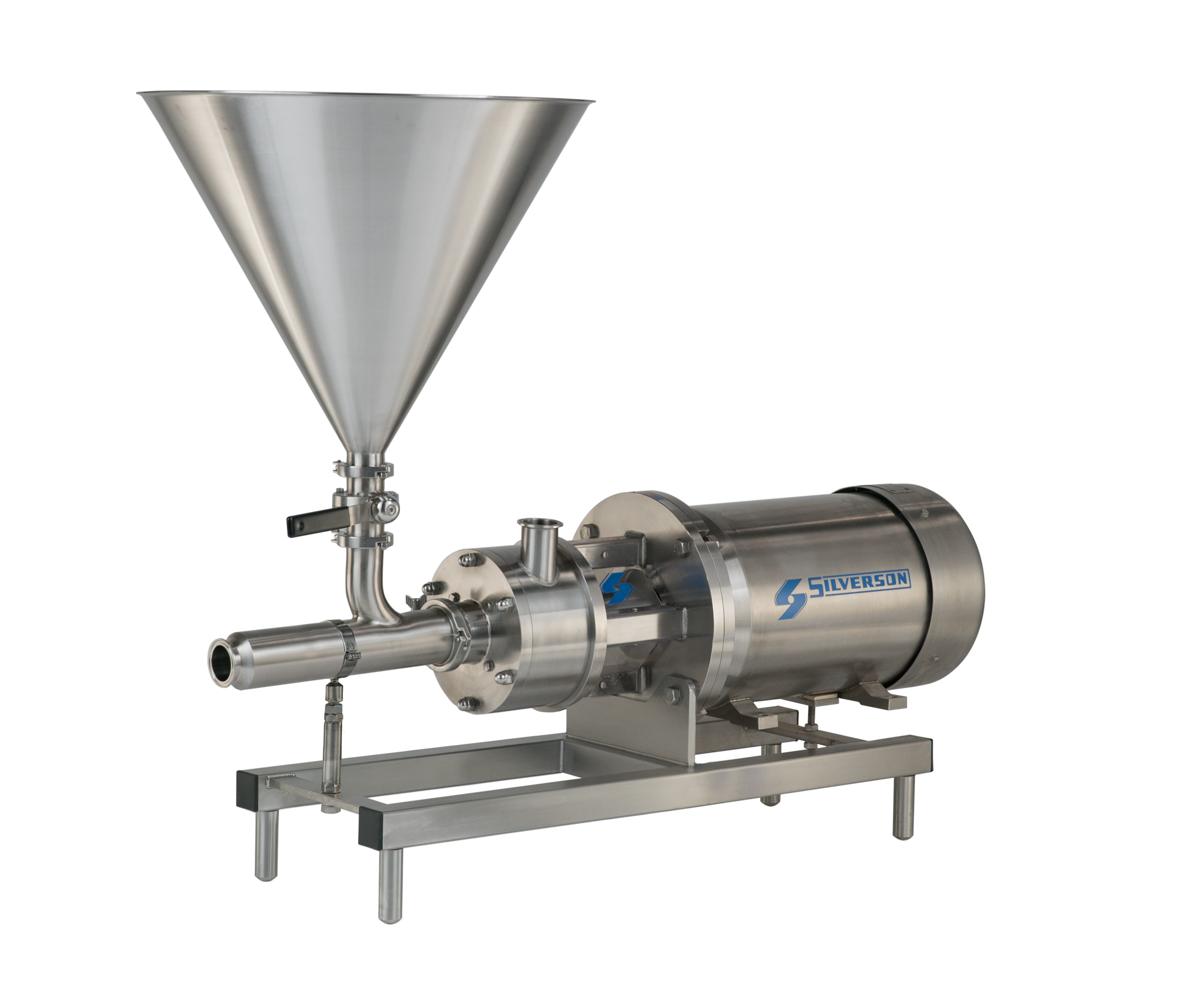

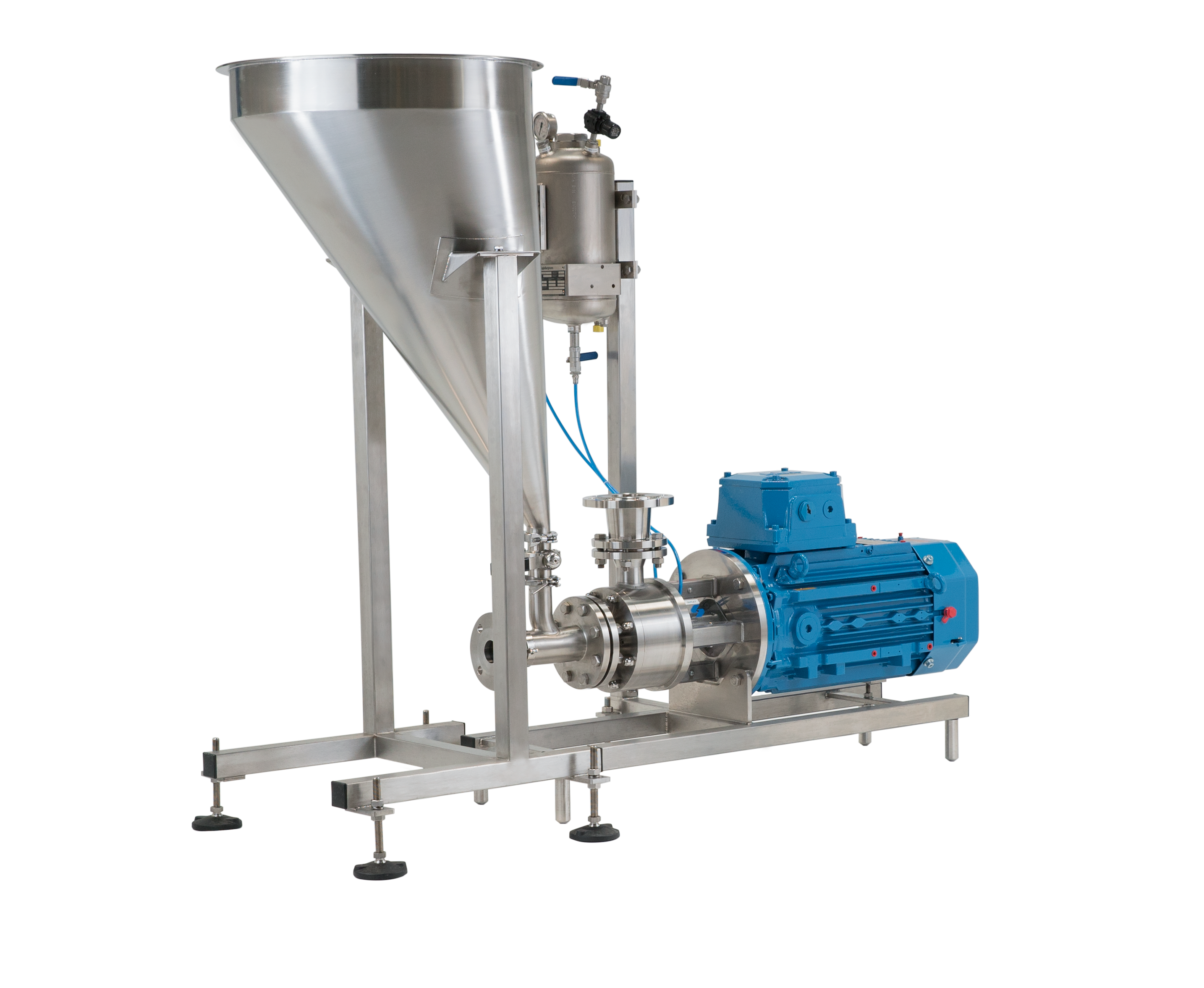

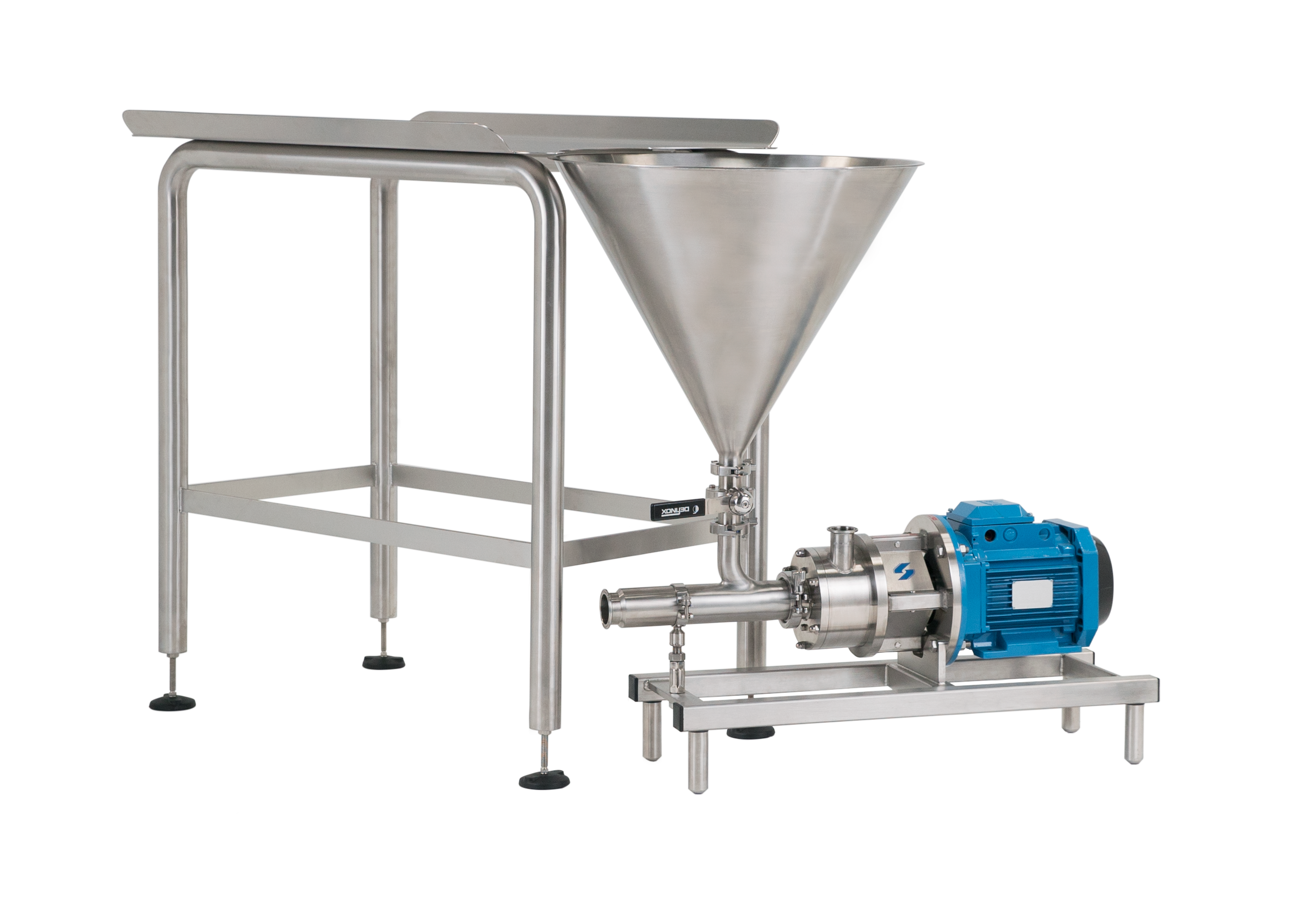

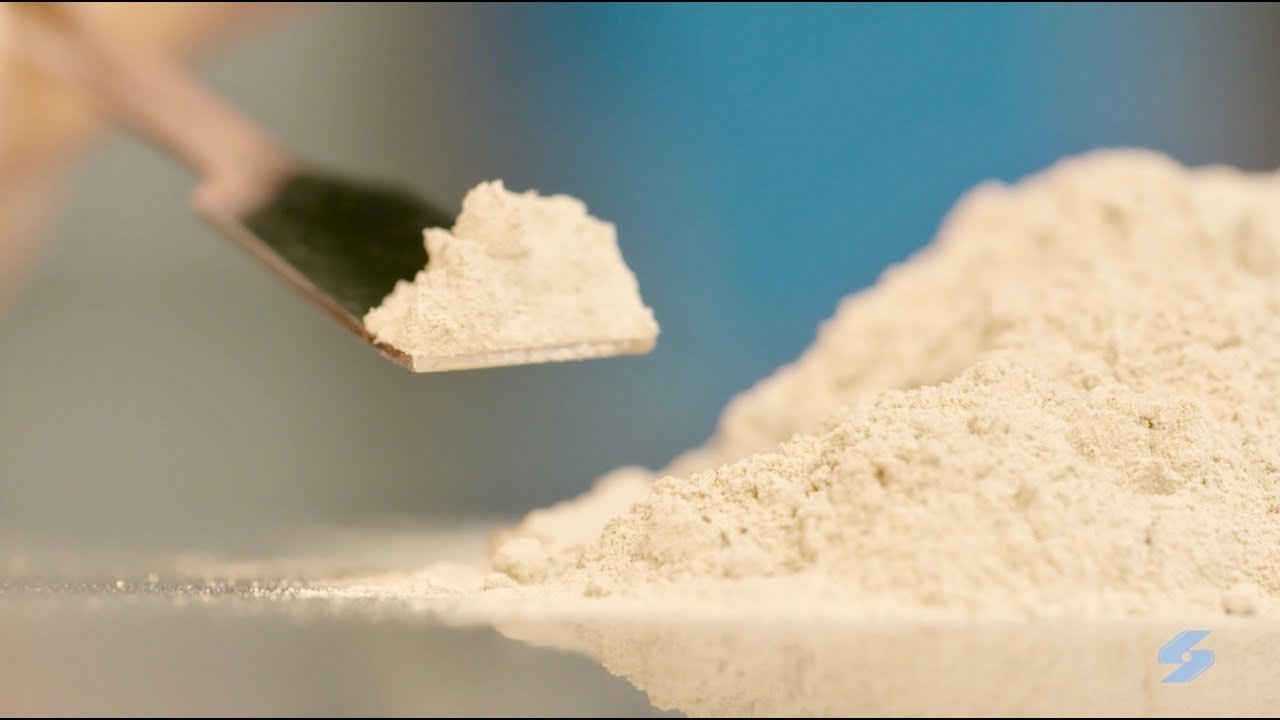

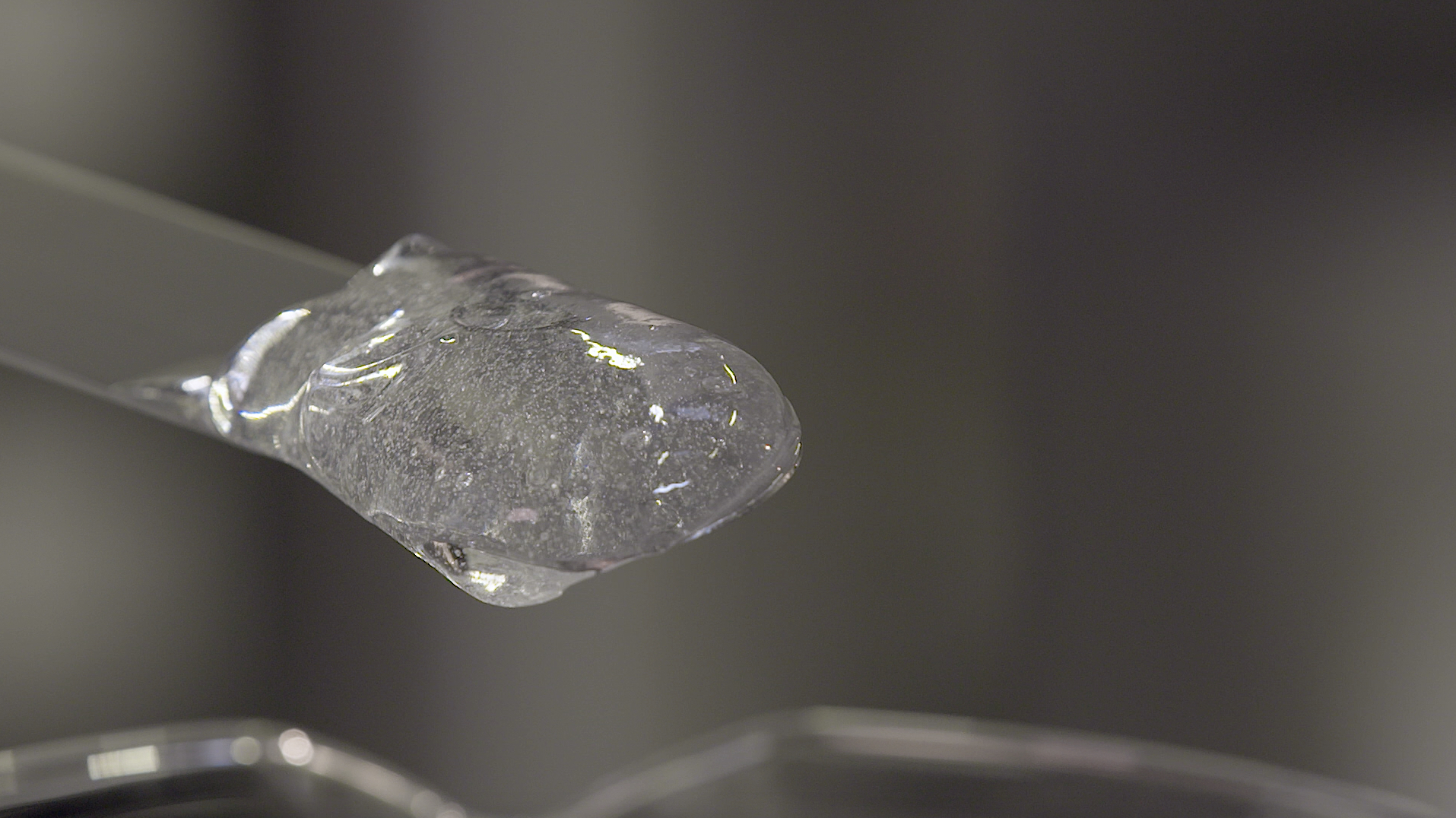

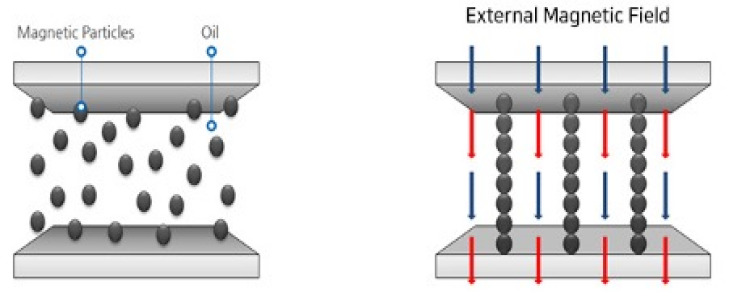

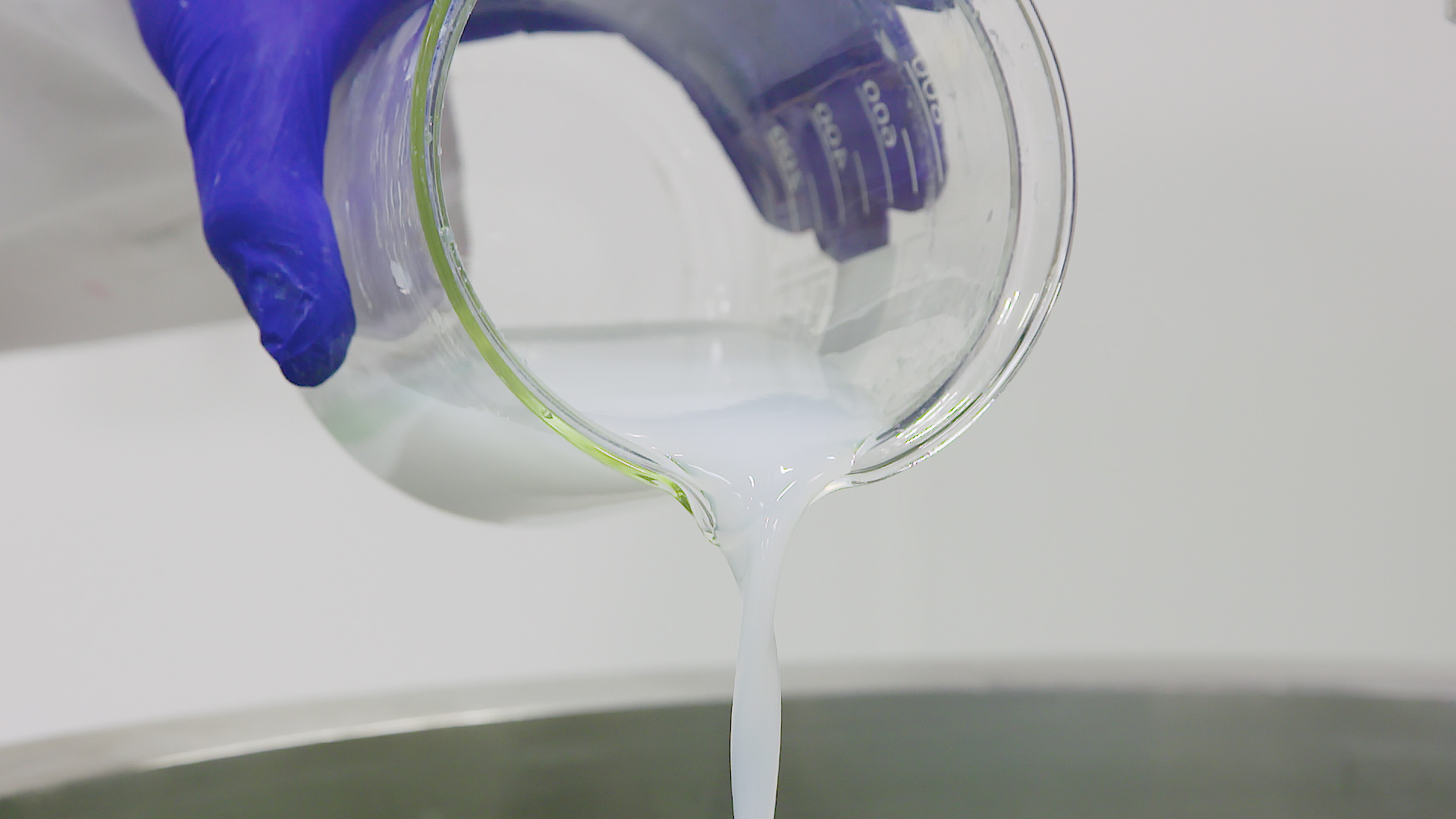

Graphene can come in lots of different forms, one of the main types is called graphene nanoplatelets which is in the form of a black powder. But there are different variations of graphene, such as graphene oxide which can come as either a liquid suspension or as a wet cake paste. Part of the problem with scaling up graphene production is that the mixing equipment needs to be able to deal with all the different forms and variations of graphene. Something which the Silverson Machines have proven themselves capable of at GEIC.

Another challenge of working with graphene is that it behaves in a different way, depending on what it is being put into. The different grades of graphene behave differently in different materials. As it is a new material, having only been around for about 20 years, part of GEIC research is finding out how to get graphene to behave in the way they want and again Silverson mixers have been crucial in finding solutions and achieving the results they want.

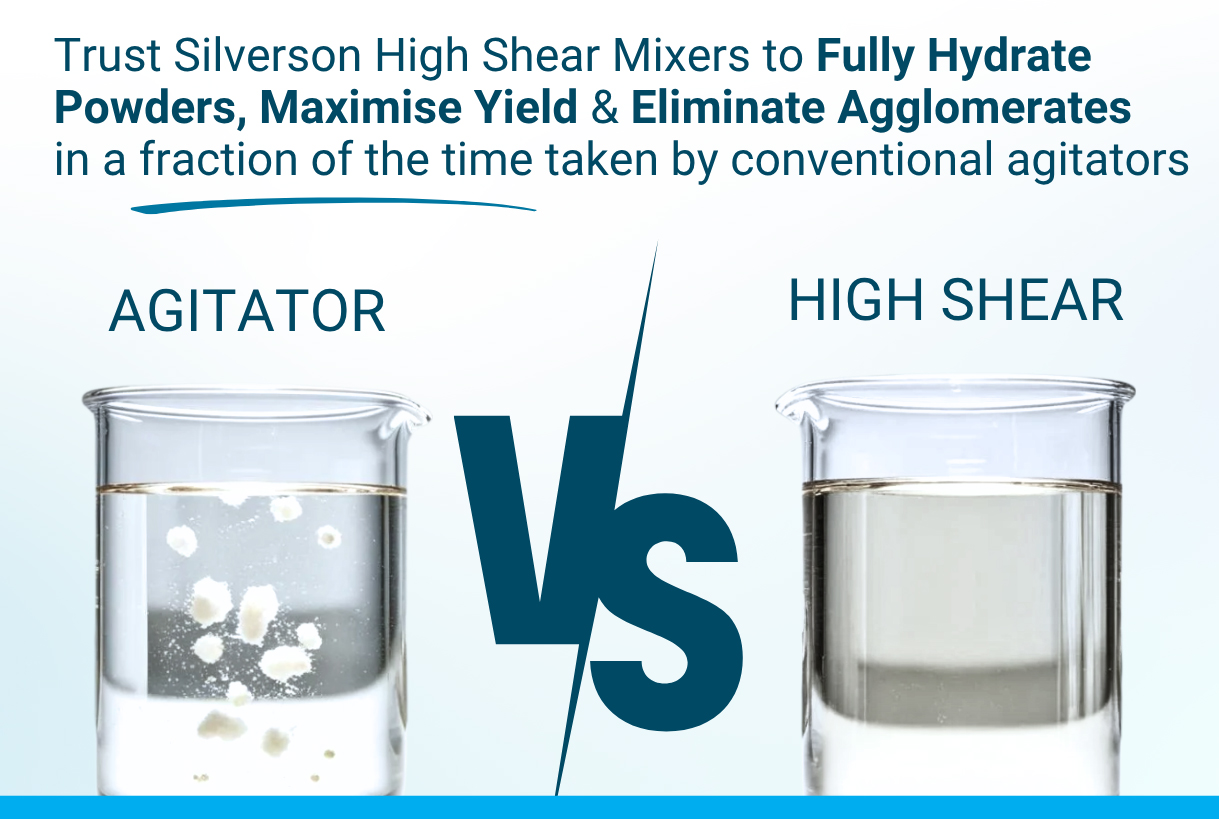

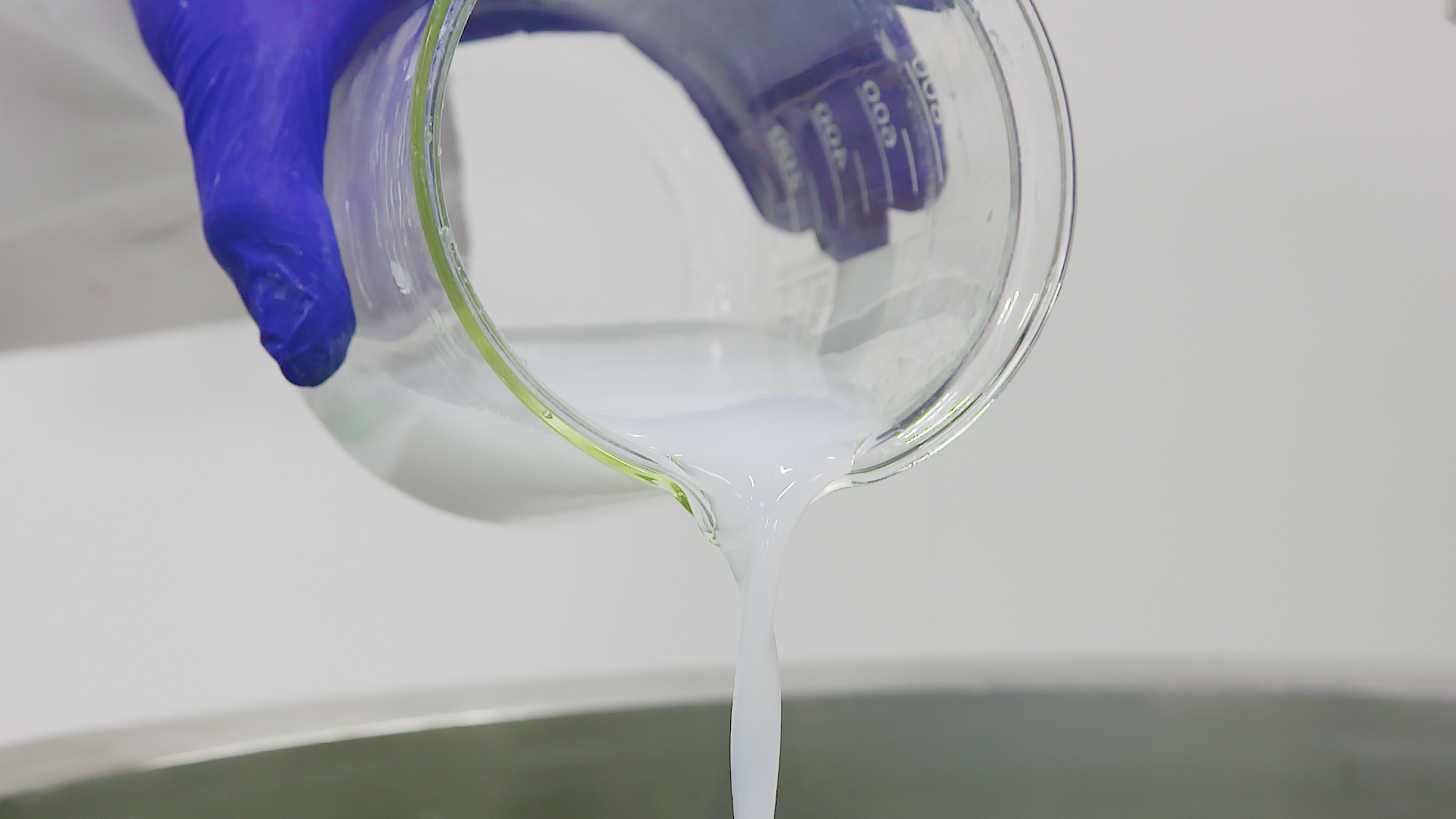

For example, graphene can be very tricky to disperse in water or liquid base formulations as it tends to agglomerate when added to liquid bases. It naturally begins to want to go back to its graphitic state and restack. If the graphene is not dispersed into the liquid base thoroughly, the end properties which are so desirable in these products, will not be achieved as the amounts of graphene in the formulation is minimal. So it is essential that dispersion is done efficiently and properly.

Pioneering Graphene Breakthroughs with Silverson High Shear Mixing

Pioneering Graphene Breakthroughs with Silverson High Shear Mixing

How are Silverson High Shear Mixers being used?

In the infancy of graphene research, Silverson mixers were used in one of the successful techniques used to extract graphene from graphite, through shear exfoliation. This process used the high shear of a rotor stator mixer t...

+ Read more

How are Silverson High Shear Mixers being used?

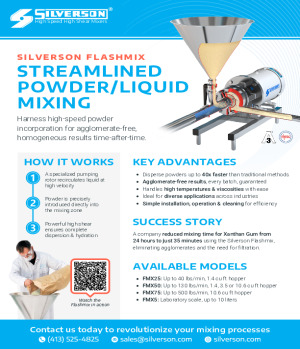

In the infancy of graphene research, Silverson mixers were used in one of the successful techniques used to extract graphene from graphite, through shear exfoliation. This process used the high shear of a rotor stator mixer to exfoliate defect-free, few-layer graphene from graphite in solvent systems or certain surfactants.

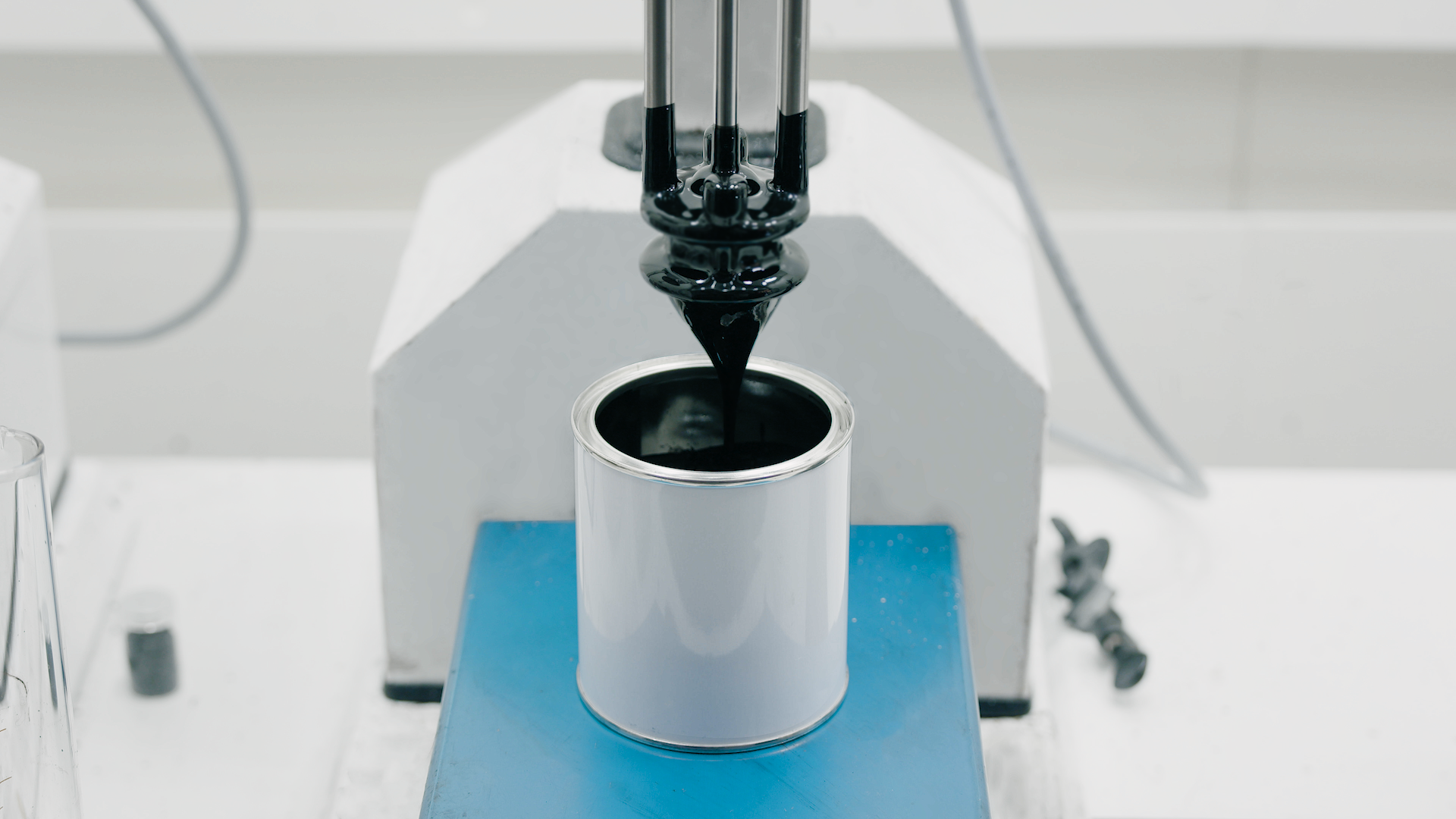

Now that research has moved on, the high shear energy of Silverson mixers is still proving essential for graphene formulations at a laboratory scale. The high shear energy ensures that the graphene is dispersed well throughout an entire mix so the desired end properties are achieved. GEIC have tested these formulations under microscopy and have seen that the level of dispersion achieved with a Silverson Laboratory mixer, far outperforms conventional lab stirrers. Not only can the Silverson disperse the graphene effectively, it will also disperse any pigments, dispersants or resins in the formulation as well, completing the whole process.

One of GEICs main focuses is bridging the gap between what has been done in the laboratory and scaling up to pilot production, which is what industry needs in order to commercialise graphene products. To this end, the team at GEIC has recently purchased a production scale Silverson Batch Mixer. This has completely changed how they work on collaborative projects with their partner companies from different industries and how they can provide large scale samples for them. Since using the Batch mixer, GEIC's production times have been reduced from several days to a few hours.

Silverson designs, engineers and constructs its laboratory mixers to the same precision tolerances as its production units, with comparable rotor tip speeds and shear rates across the entire product line. Because of this, all our machines produce scalable results, so replicating lab-scale results with production scale mixers is ultimately achievable. This was first demonstrated in relation to graphene in the research published in the journal Nature Materials, where a team at the Centre for Research on Adaptive Nanostructures and Nanodevices, Trinity College Dublin, Dublin, Ireland, showed scalable graphene production is possible.

Dr Lisa Scullion, says in the video: "One of the main benefits is that we can scale up directly from the smaller mixers to the bigger mixers, and we've tested that and we know that the Silverson systems are reliable and versatile throughout the whole process."

To find out more, read our application report and watch the video on the Silverson website: www.silverson.com

- Read less

Published by Silverson Machines on Feb 16, 2024