Dispersion and hydration of Alginates

Alginates are natural polymers (biopolymers) or hydrocolloids that are obtained from brown seaweed and are water-soluble when mixed under the correct conditions. Alginates are used as thickening, stabilizing and gelling agents, find out more about how Silverson High Shear Mixers can help to improve the dispersion and hydration of alginates when used in place of conventional mixing equipment.

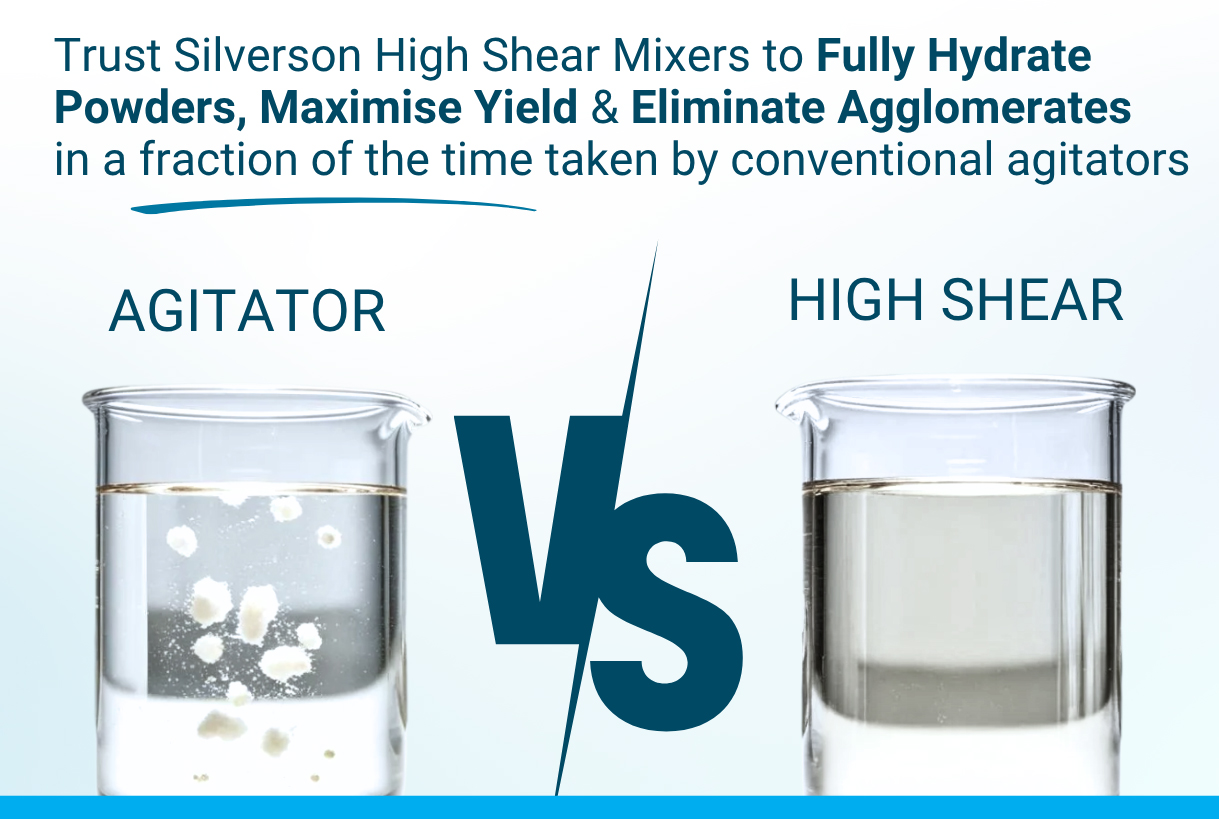

Alginates are available in powdered and granular form, both of which have a strong tendency to form lumps when added to water and a number of dispersion and hydration methods are used to overcome this. These include premixing the dry alginate with another powdered ingredient such as salt or sugar, to separate the particles and allow for easier dispersion with simple stirrers, but this leads to increased processing times. Controlled powder addition into liquid can help reduce the formation of agglomerates but this method is impractical for large scale productions and can be exacerbated by operator error. Combining alginates with other gums, such as pectin, increases the viscosity dramatically which can lead to problems with localized mixing when the mixing equipment is unable to handle the viscosity increase and continue to move the product around the vessel.

Agglomerates can easily form, even when steps are taken to reduce the risk, so how can these problems be solved? - with High Shear Mixing!

How to Mix Alginates with Silverson High Shear Mixers

How to Mix Alginates with Silverson High Shear Mixers

Silverson Machines’ high shear mixing technology effectively disperses alginates in a fraction of the time taken by conventional mixers and agitators. Here’s how it works:

The vessel is charged with deionized water and recirculation through the Flashmix is started. The alginate is ad...

+ Read more

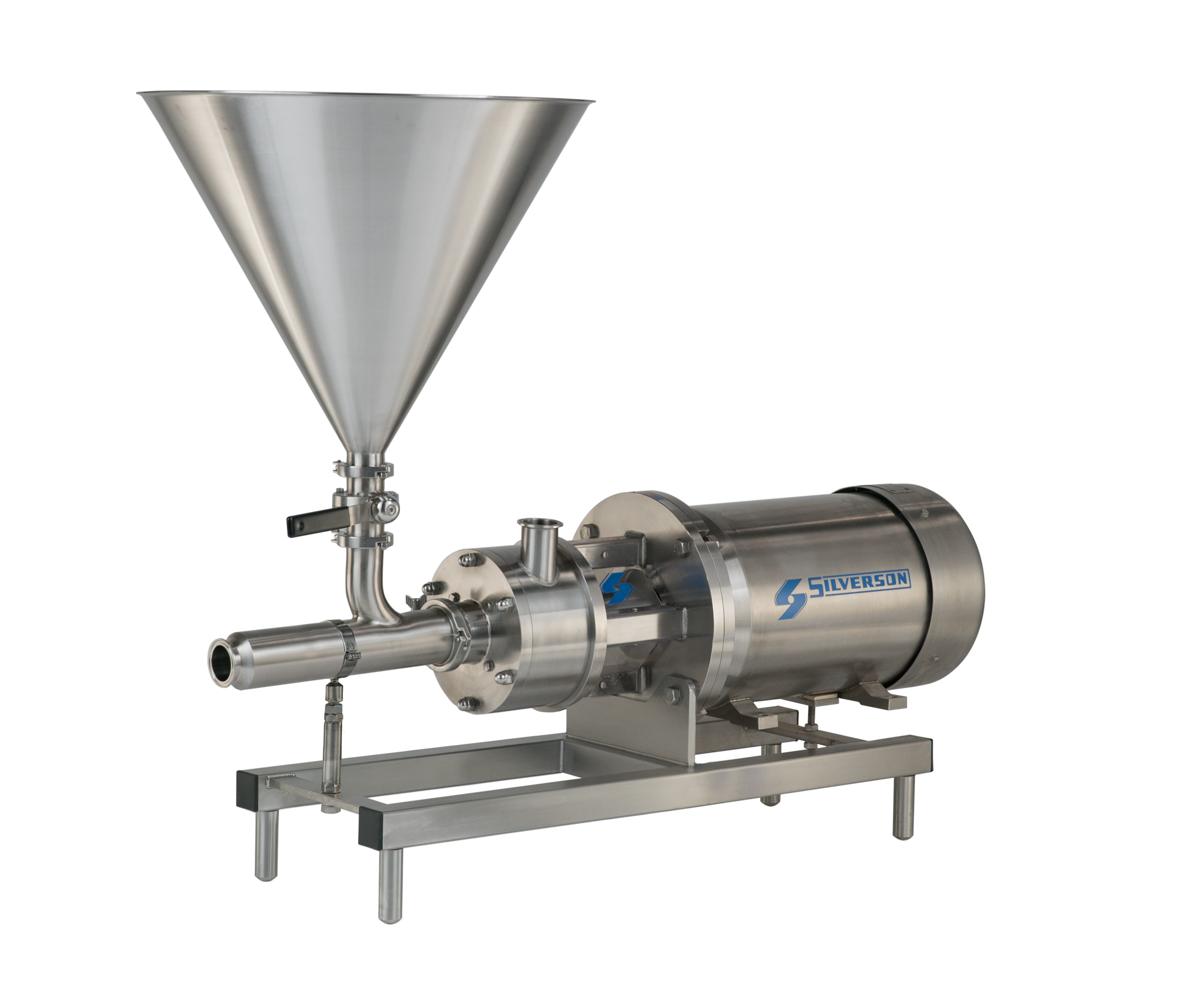

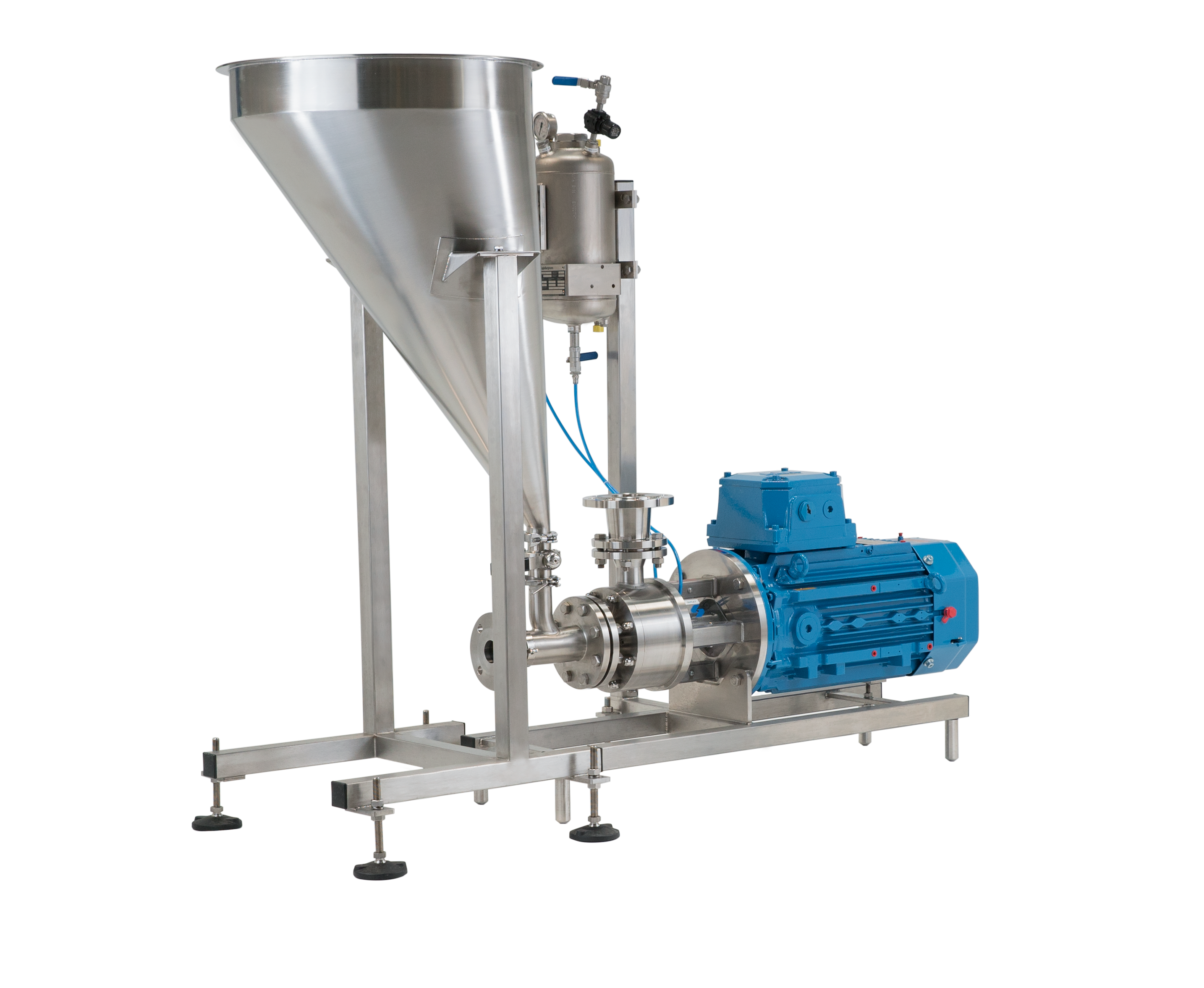

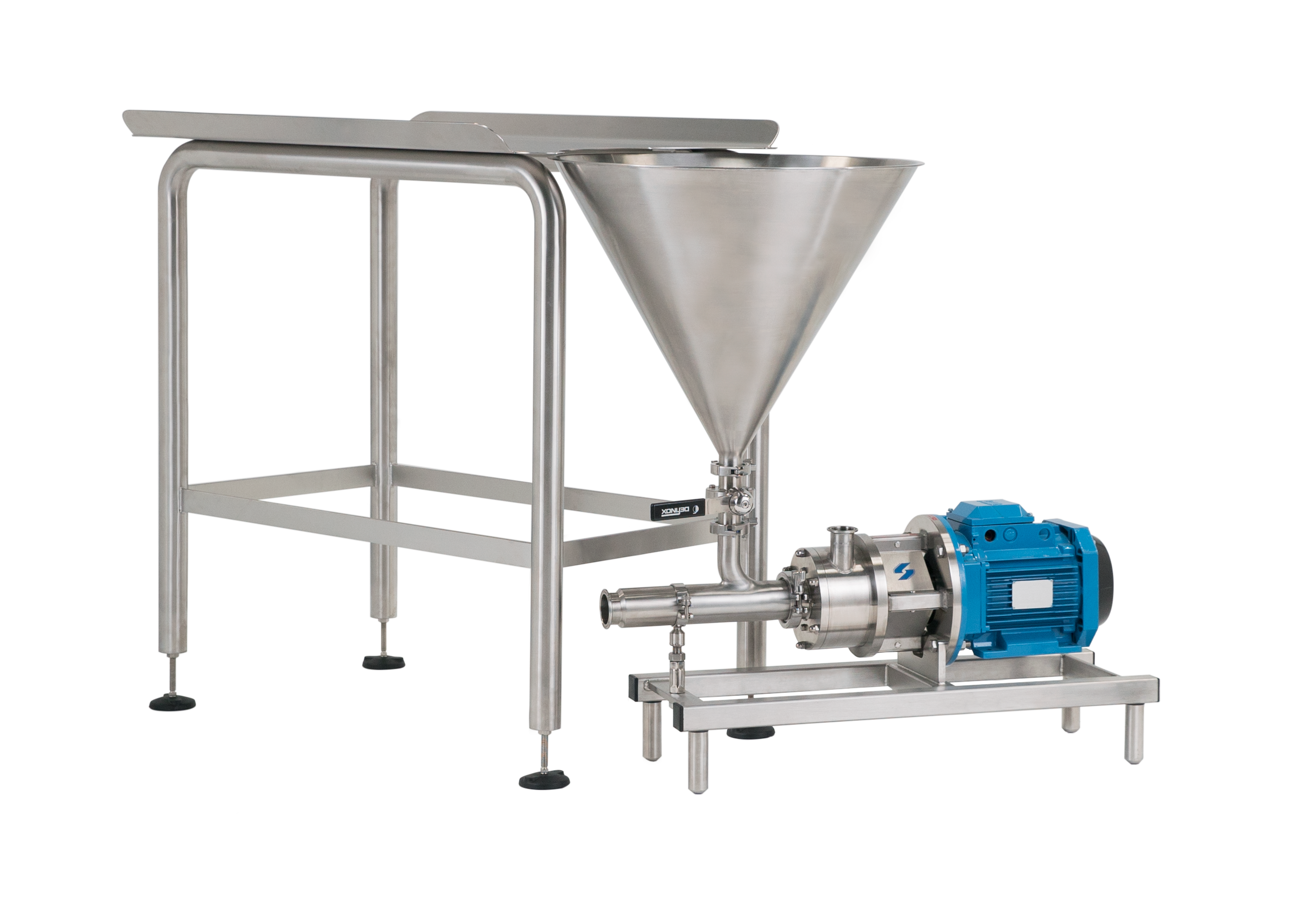

Silverson Machines’ high shear mixing technology effectively disperses alginates in a fraction of the time taken by conventional mixers and agitators. Here’s how it works:

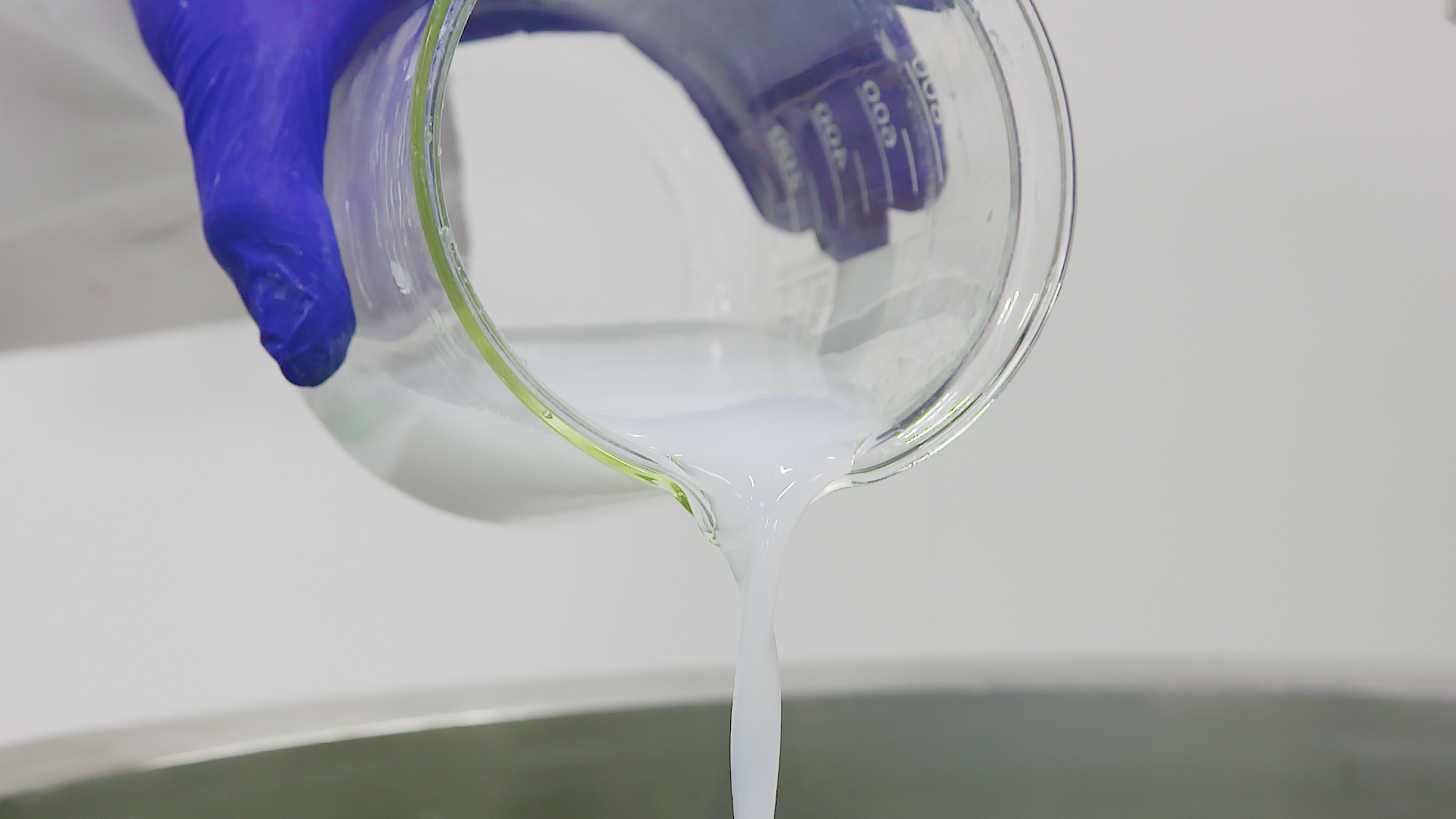

The vessel is charged with deionized water and recirculation through the Flashmix is started. The alginate is added to the powder feed hopper and when the valve is opened it is drawn directly into the high-velocity liquid stream.

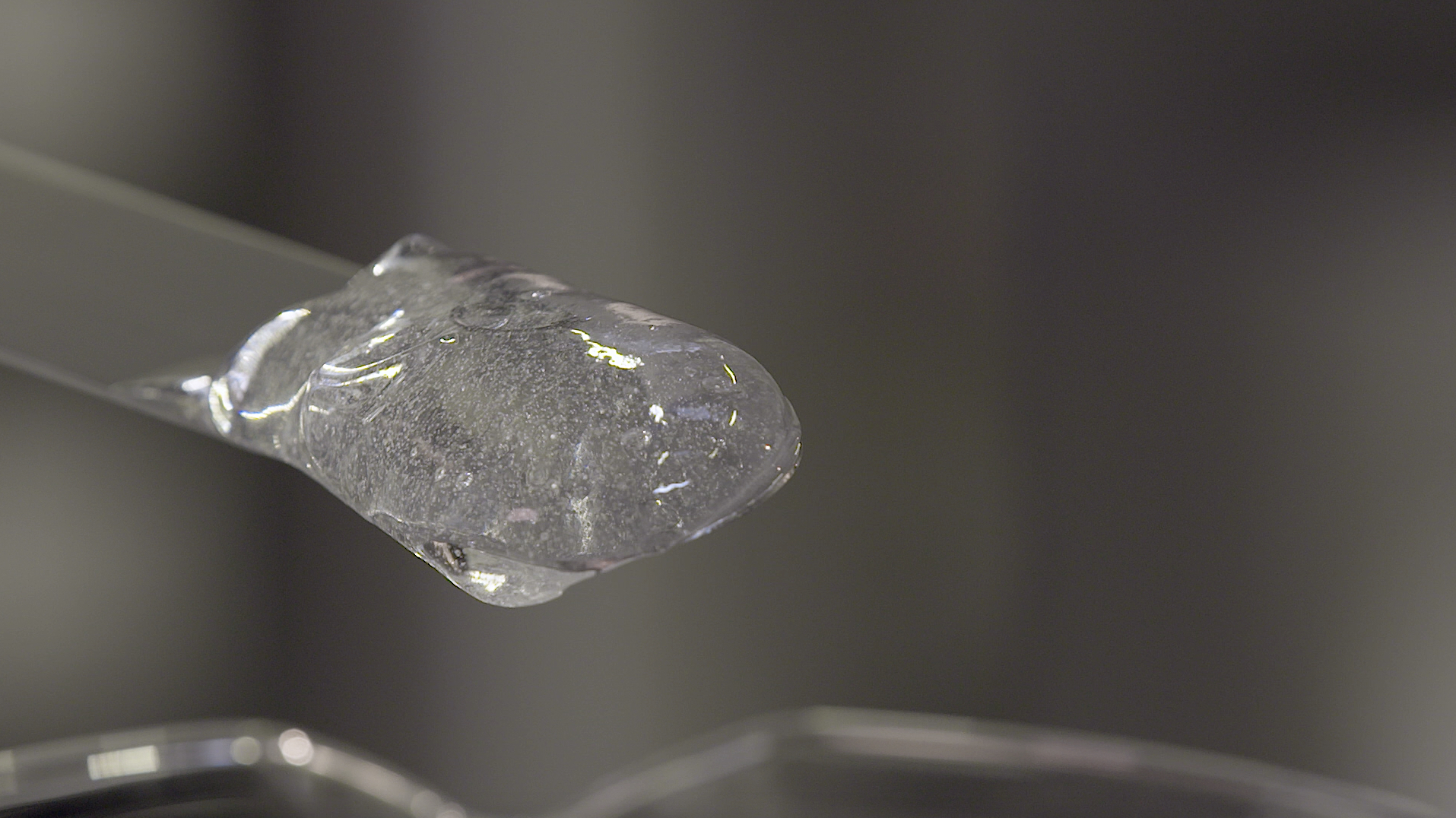

The powder/liquid mix passes immediately into the rotor stator workhead and is subjected to intense mechanical and hydraulic shear. This ensures that it is completely dispersed and agglomerate-free.

To find out more, visit the Silverson website, or contact us today to discuss your mixing requirements.

- Read less

Published by Silverson Machines on Aug 10, 2023

Silverson Machines

www.silverson.com

E: [email protected]

T: 413-525-4825

Address

355 Chestnut St

East Longmeadow, MA

01028

United States

Show map

Visit our profile