FMX25 purchased to produce shock absorbers for motor vehicles

A company has purchased a Flashmix FMX25 for dispersing metal powder into hydrocarbon oil to produce a smart material used as a shock absorber in semi-automotive vehicle suspensions and prosthetic limbs.

A company has purchased a Flashmix FMX25 for dispersing metal powder into hydrocarbon oil to produce a smart material used as a shock absorber in semi-automotive vehicle suspensions and prosthetic limbs.

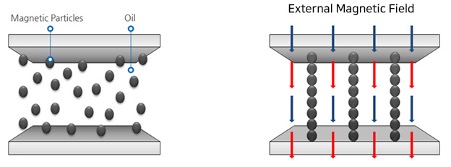

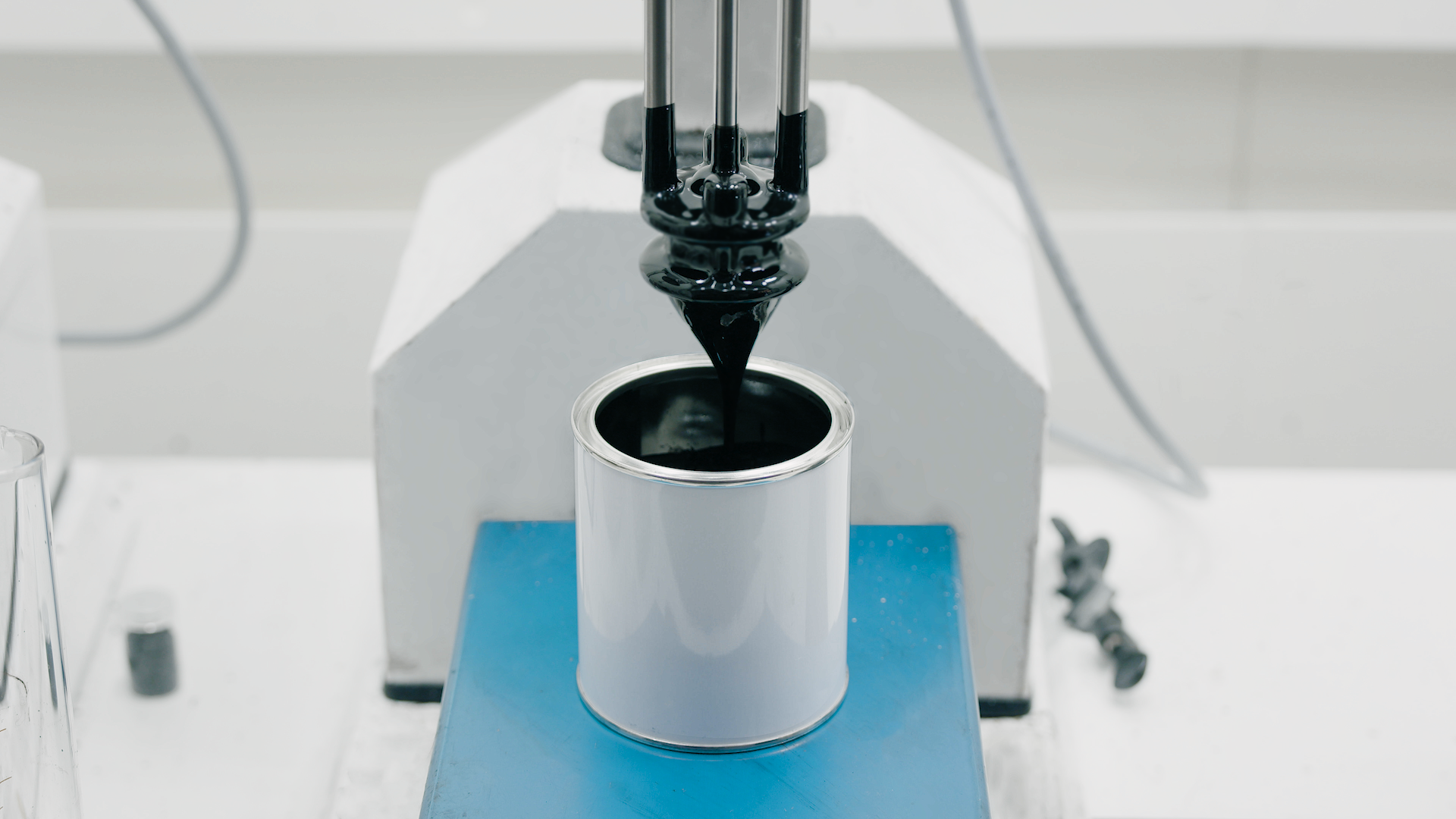

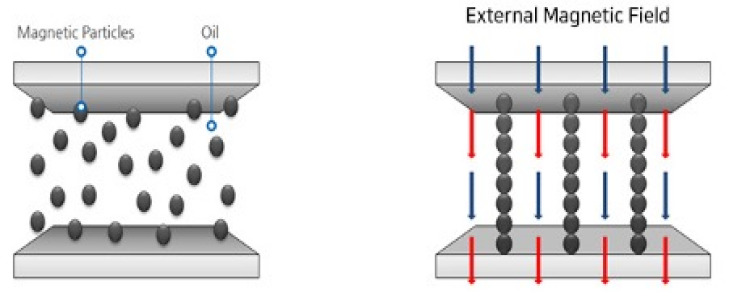

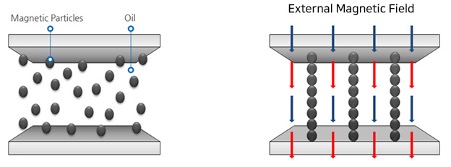

Magneto-Rheological Fluid (MRF) is composed of oils filled with metal particles (normally Iron) and other functional additives such as surfactants that surround the metal particles to protect them and help keep them suspended within the fluid. These fluids are controlled by an external magnetic field generated from an induced current.

The metal particles make up approximately 20 - 40% of the volume of the fluids. The particles are between 3 - 10 microns but have a powerful effect on the fluid's consistency; when exposed to a magnetic field the particles line up, thickening the fluid dramatically. This thickening process takes less than 1 second (twenty-thousandths of a second).

The ability to change from liquids to semi-solids almost instantly makes these fluids useful for dampening impacts and vibrations in items like car shock absorbers.

The company that produces MRF contacted Silverson for help with particle size distribution/reduction. They had been using a...

+ Read more

The ability to change from liquids to semi-solids almost instantly makes these fluids useful for dampening impacts and vibrations in items like car shock absorbers.

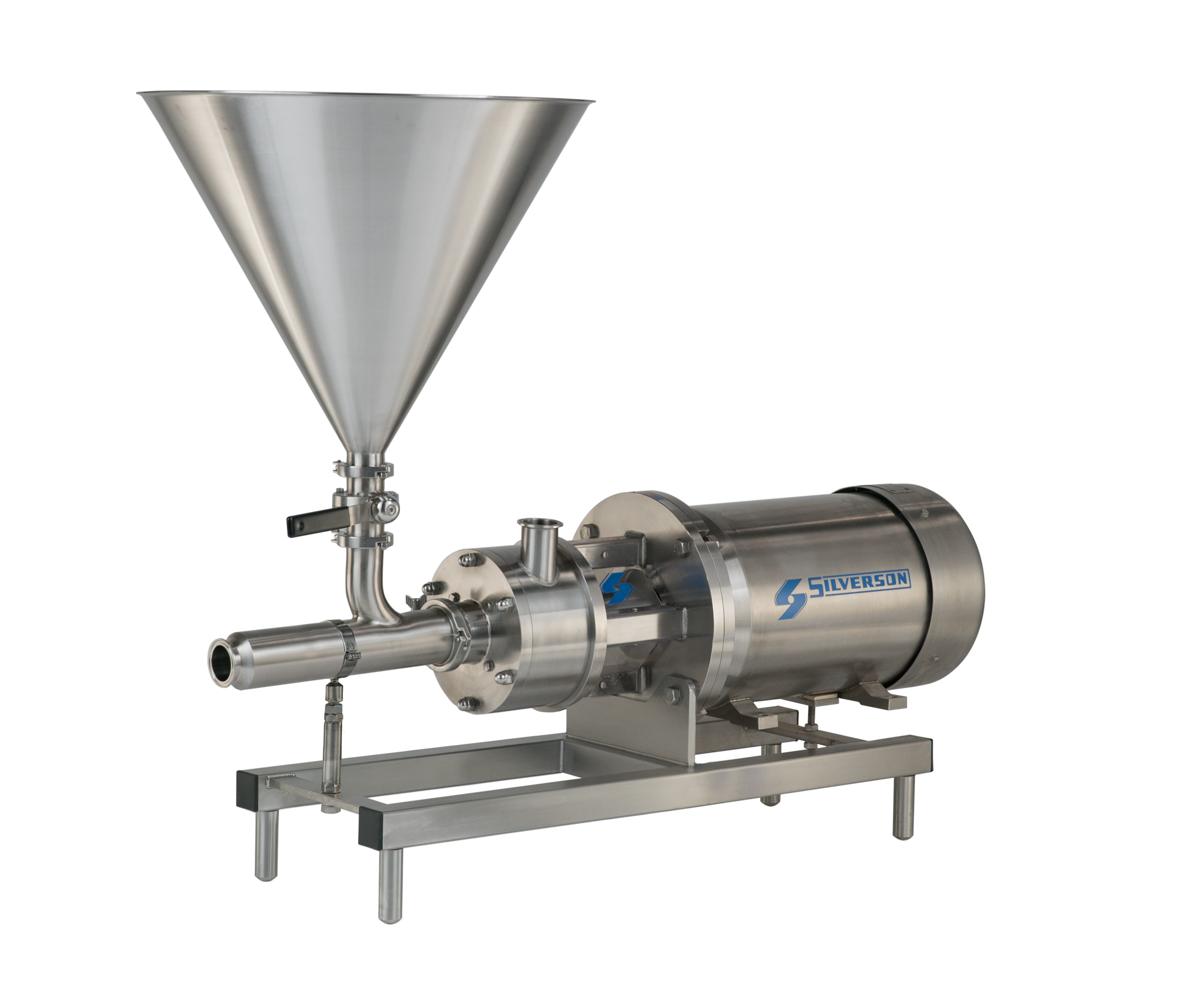

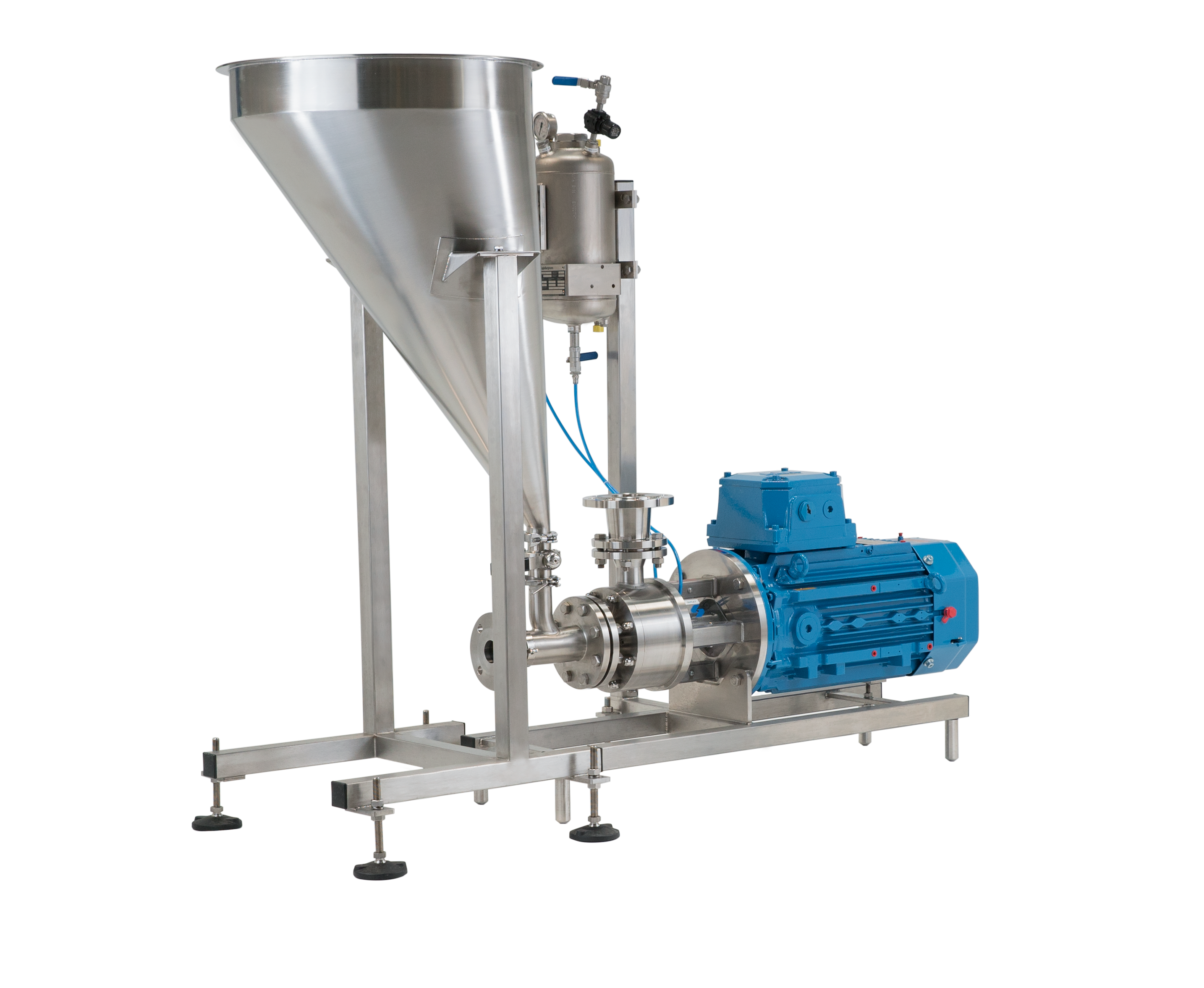

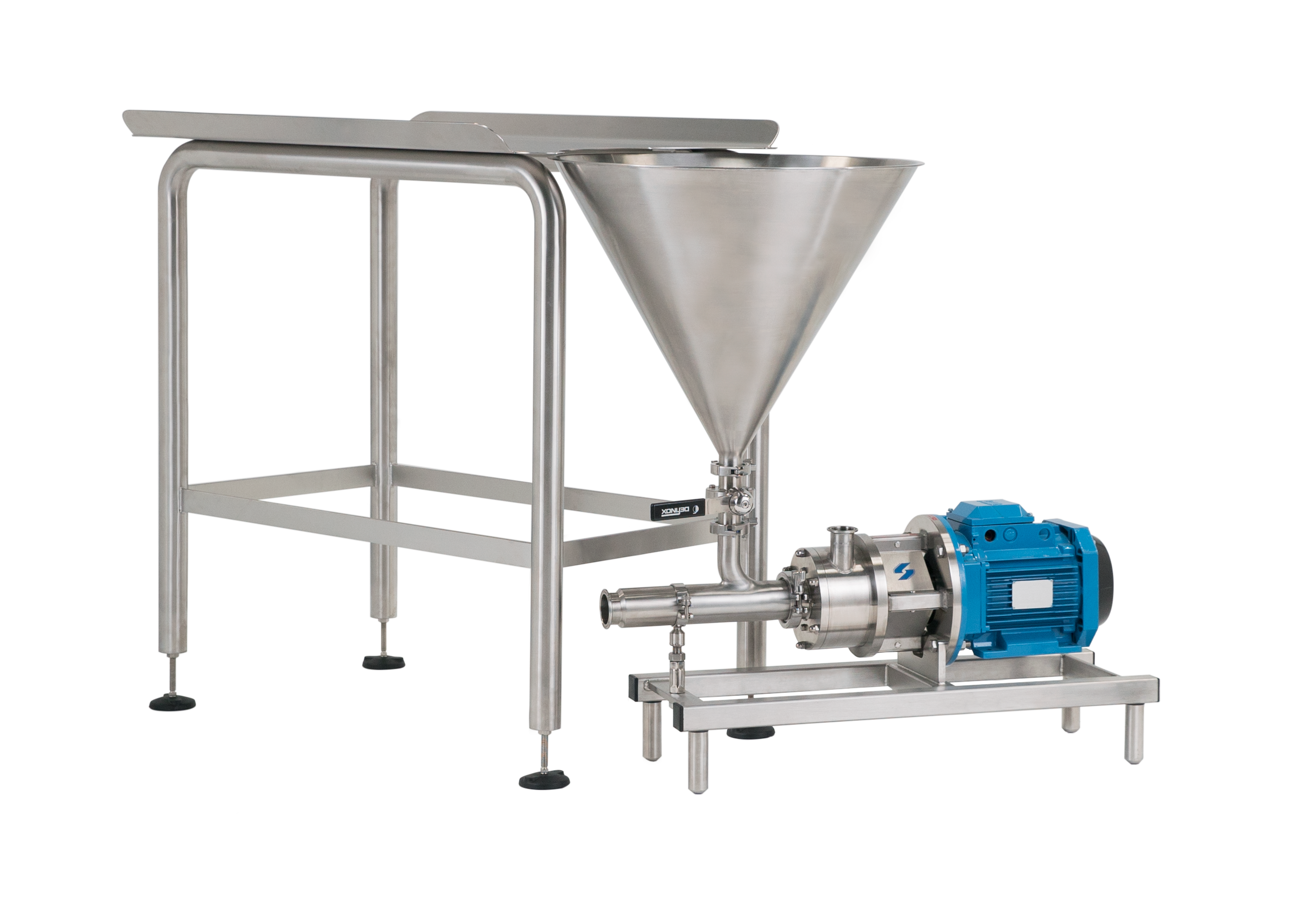

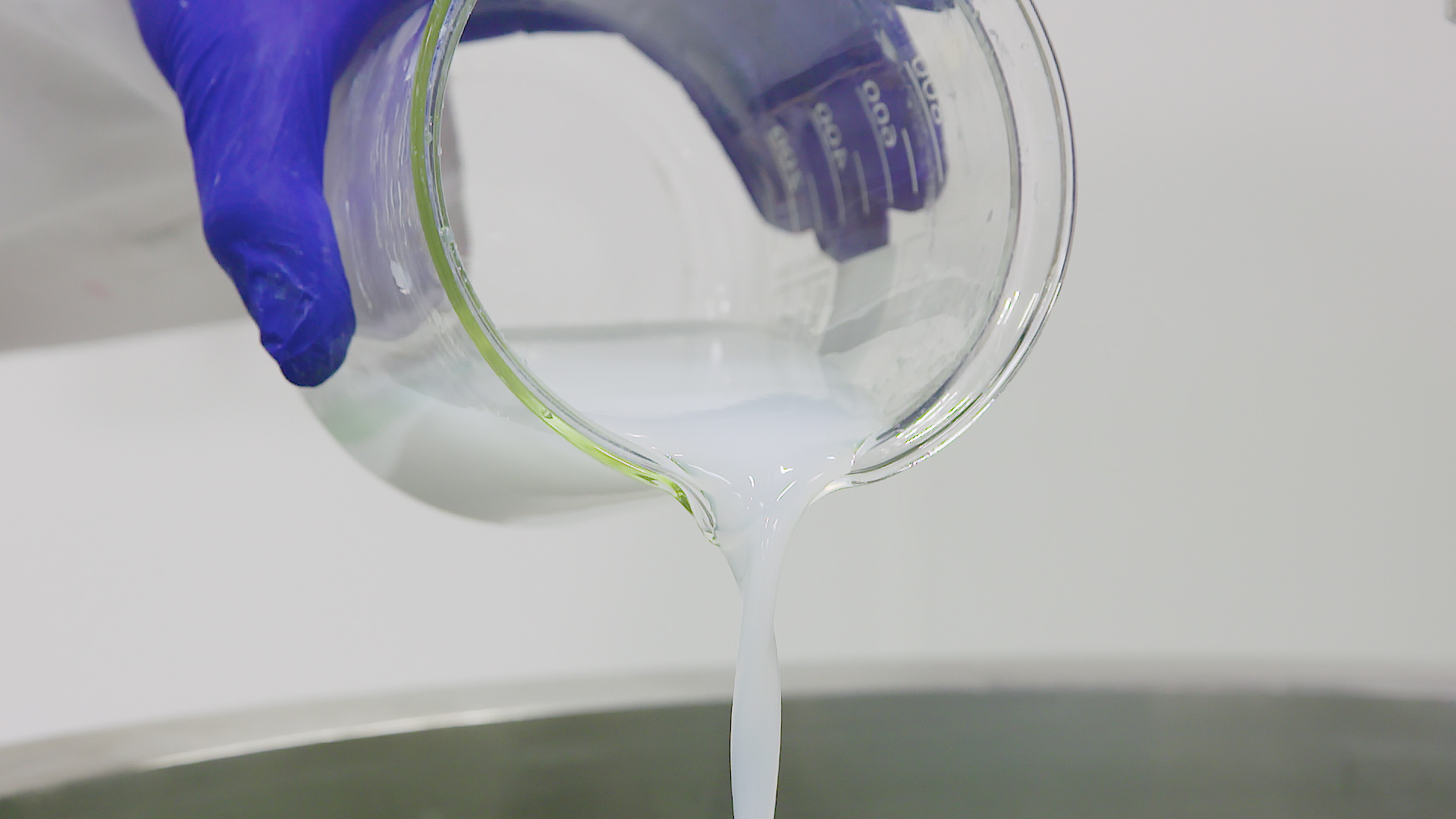

The company that produces MRF contacted Silverson for help with particle size distribution/reduction. They had been using a dissolver to disperse 26 gallons of metal powder into hydrocarbon oil. The process was taking 2 - 3 hours and the resulting product did not meet the desired particle size.

After discussing their application, the FMX25 was recommended and then tested in the laboratory. The mixer was started, and 1.3 gallons of metal powder was added to 16 gallons of recirculating hydrocarbon oil. The powder needed to be introduced into the mix very slowly because of the rapid increase in viscosity, with the end product being between 3000 - 4000 cps. The mix was recirculated for 10 minutes before a test was carried out to analyze the fineness of the metal powder.

After this short amount of time, the results were better than the dissolver, so much so that 10 minutes of mixing was enough to reduce the particles to the size the company was happy with, and they purchased the FMX25.

- Read less

Published by Silverson Machines on Oct 11, 2022

Silverson Machines

www.silverson.com

E: [email protected]

T: 413-525-4825

Address

355 Chestnut St

East Longmeadow, MA

01028

United States

Show map

Visit our profile