Custom Powder/Liquid mixing solutions

At Silverson we know that anyone mixer is not right for everyone. That’s why we will listen to your specific needs to make sure we create the right mixer for you. We design and build every Silverson mixer ourselves. Our extensive in-house engineering and machining facilities allow us to design and manufacture mixers customized to your precise needs.

At Silverson we know that anyone mixer is not right for everyone. That’s why we will listen to your specific needs to make sure we create the right mixer for you. We design and build every Silverson mixer ourselves. Our extensive in-house engineering and machining facilities allow us to design and manufacture mixers customized to your precise needs.

Below are some examples of how we have been able to customize our Powder/Liquid mixers to meet customers specific requirements:

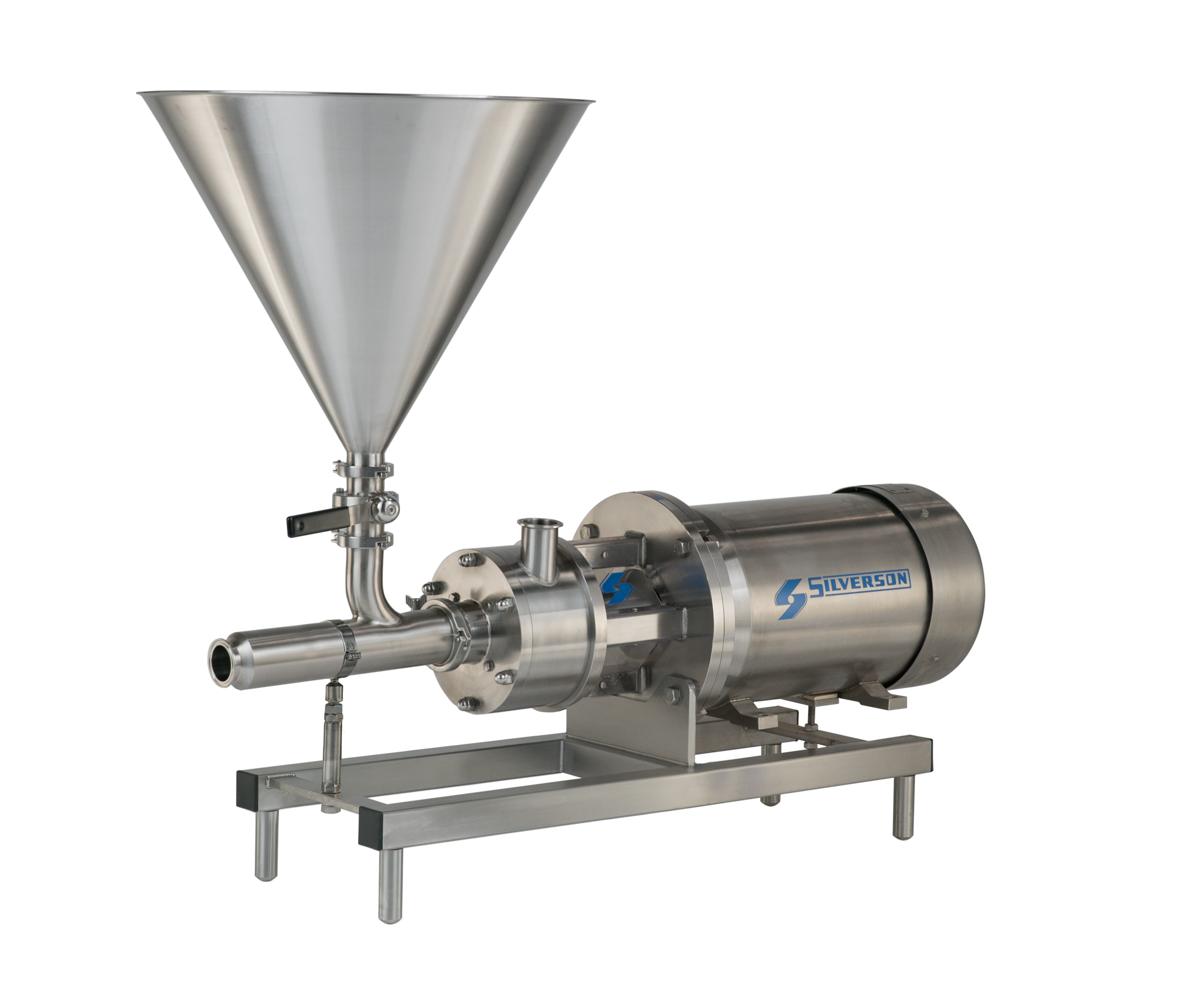

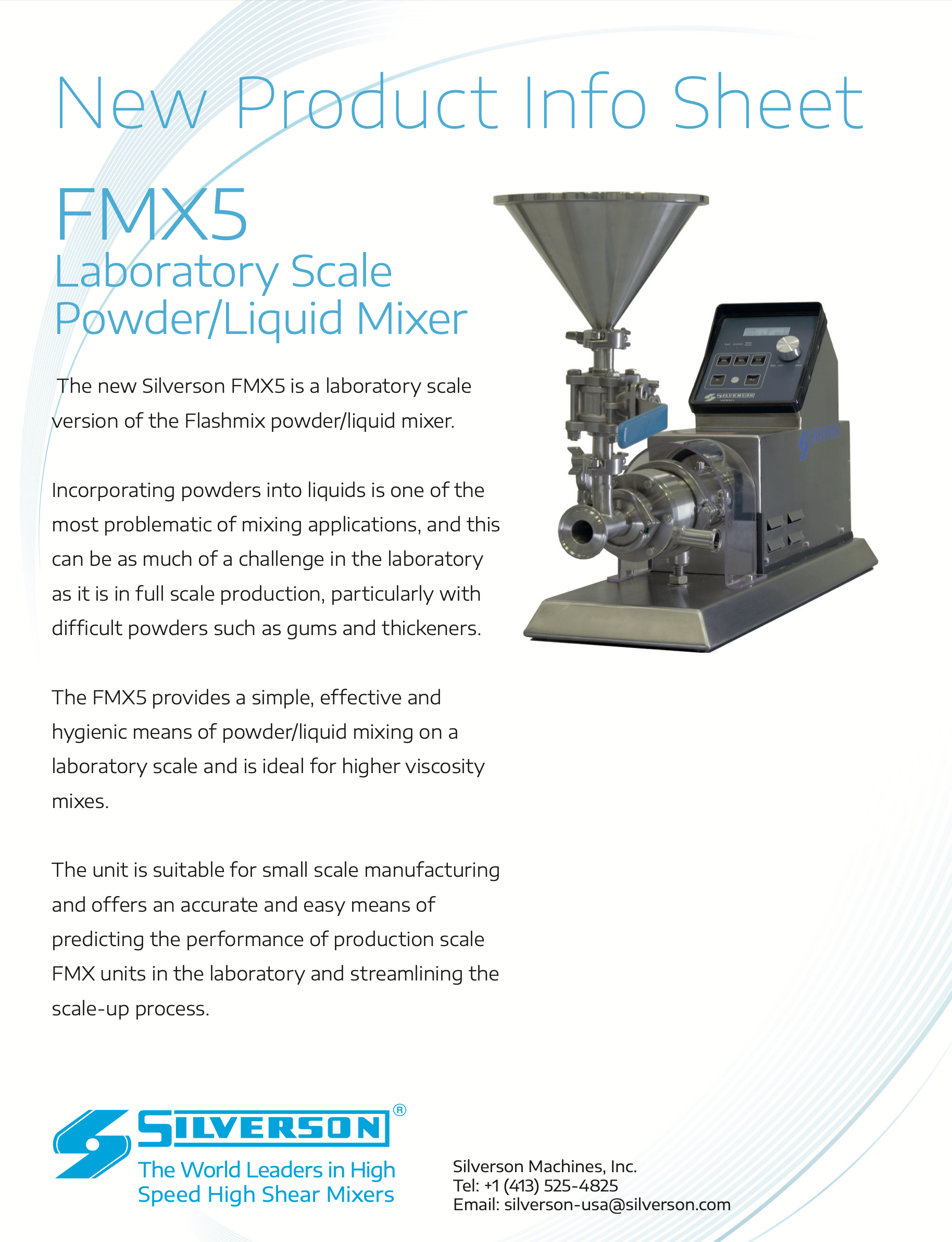

FMX with additional hopper for incorporating liquids

A food company has recently purchased a Flashmix with an additional hopper retrofitted onto the machine for incorporating liquids.

The company is a previous customer of Silverson and had been using an In-Line mixer with a 238-gallon steam jacket heated vessel for processing starch liquor. They were developing a new product that required suspension of small seeds in the liquor and wanted something that would make material handling easier for them.

After having looked on the Silverson website they decided a mixer from the Flashmix powder/liquid mixer range, along with a sack table, would work best for them and a trial unit was sent to their factory.

The trials they ran went very well and the customers were very pleased with the performance of the machine and were especially impressed with how easy the Flashmix made powder handling and addition. So much so that they enquired as to whether they could add their liquid in the same way.

To meet this request an additional hopper was retrofitted onto the mixer.

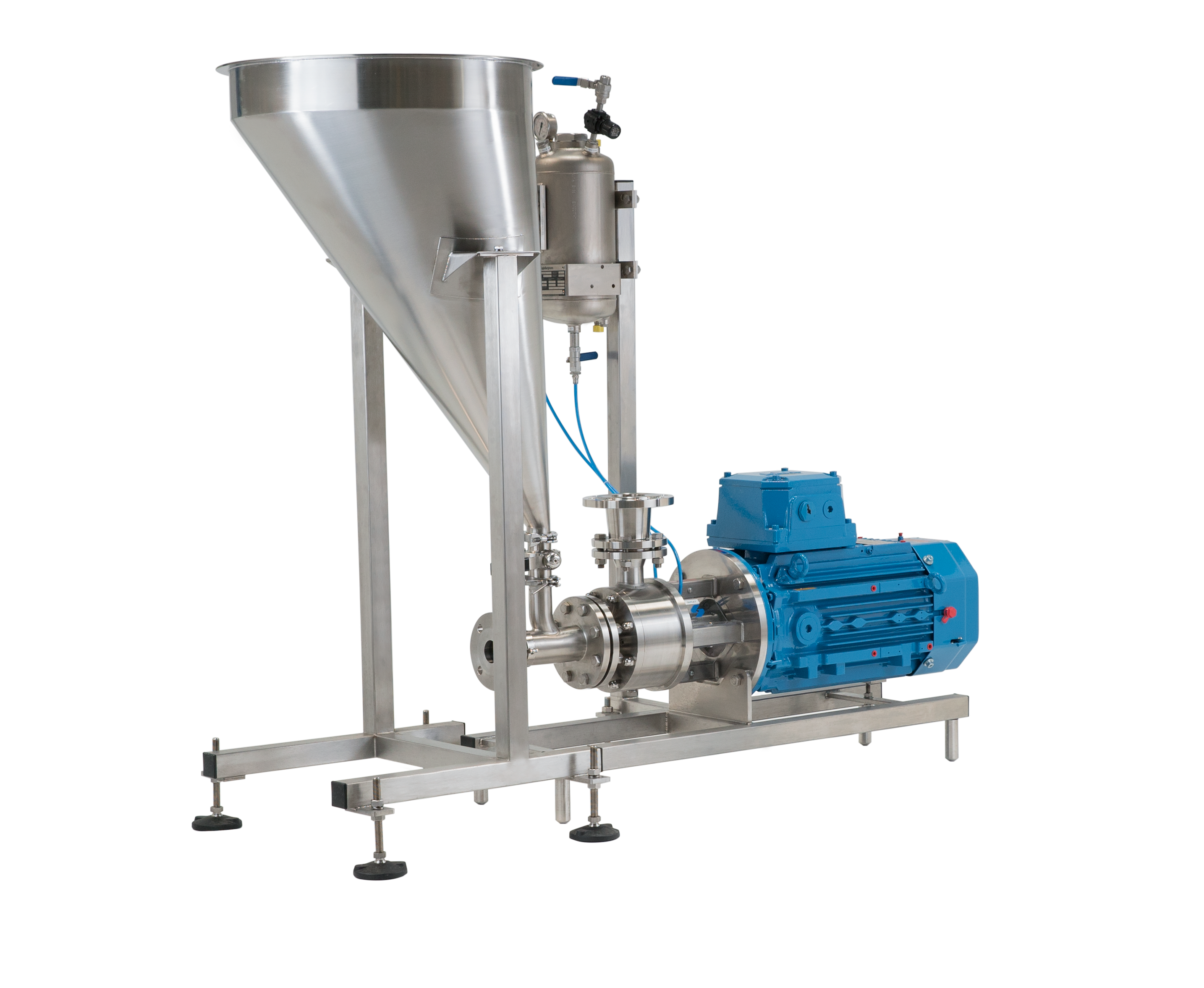

Flashmix FMX25 with integral sack table

A natural health company has taken delivery of a Flashmix FMX25 with a custom integral sack table.

The company that manufactures nutritional supplements, healthy foods, and over-the-counter supplements such as creams and vitamins, had the mixer and sack table customized to their specific needs.

The company contacted Silverson to request a duplicate of an In-Line machine they had purchased several years ago.

During discussions about their process, it was apparent that Flashmix may be more suitable for their application. After viewing some related product videos, the customer agreed that an FMX25 powder/liquid mixer would be the best mixer for the job.

The company wanted a mixer they could use in various locations and thought it would be too difficult to move the Flashmix and the free-standing sack table around separately. As a solution, Silverson designed a non-standard integral sack table and mixer as seen in the pictures below.

The customer was very pleased with this arrangement and the unit is successfully installed in their production facility.

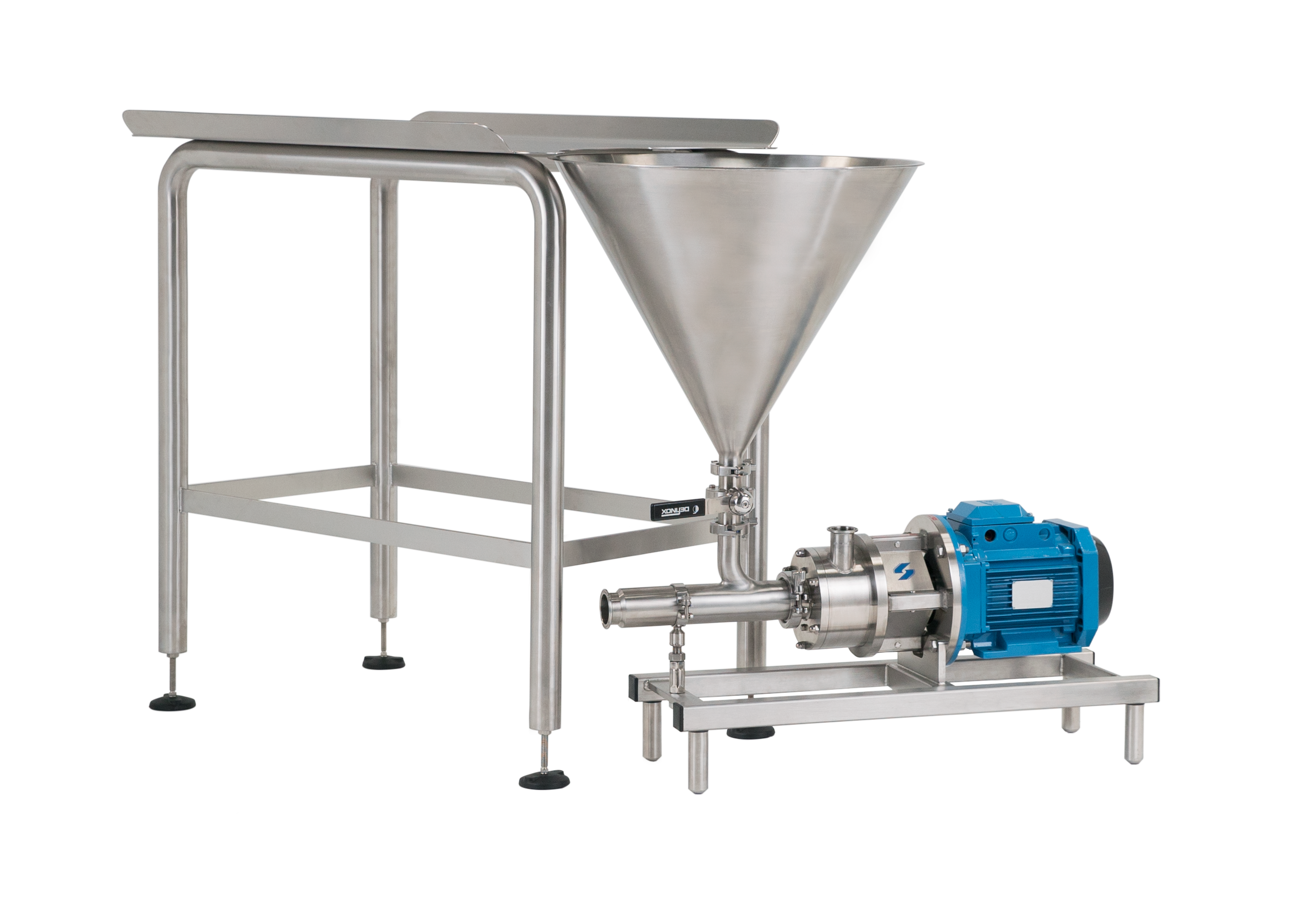

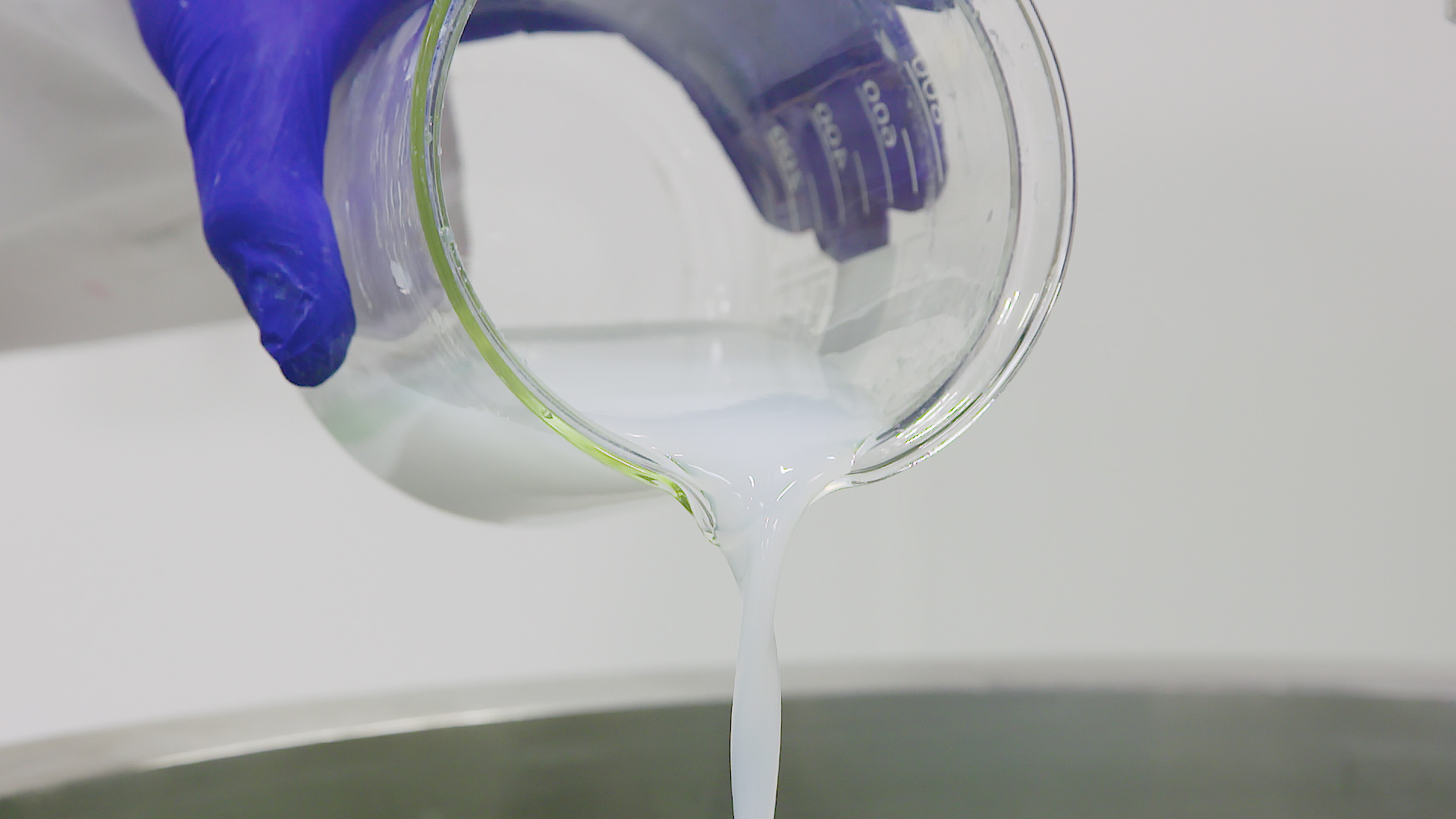

Flashmix with Ball Valve for soap production

Soap base manufacturers have recently purchased a specially modified Flashmix FMX50 powder/liquid mixer for their process, following successful trials at their site. Previously the company had been using a competitor's in-tan...

+ Read more

Flashmix with Ball Valve for soap production

Soap base manufacturers have recently purchased a specially modified Flashmix FMX50 powder/liquid mixer for their process, following successful trials at their site. Previously the company had been using a competitor's in-tank high shear mixer in their reactors but opted for the Flashmix for powder addition as they could use the mixer on all four of their tanks instead of needing a separate mixer for each tank.

After running a series of trials with a standard FMX50 in their factory, the company came up with several modifications to adapt the mixer to suit their specific process and site conditions.

The special Flashmix was configured with a 26-gallon powder feed hopper and a smaller hopper for liquid additions; allowing the customer to keep the main hopper dry. Both of the hoppers were fitted with ball valves rather than the standard butterfly valves to control powder and liquid additions help reduce/eliminate the build-up of powder on the valves and keep flow rate consistent.

The valves were specified by the customer as the mixer was to be used for a number of duties including incorporating large volumes of gum to thicken their soap product.

The machine was to run on an almost continuous basis to produce repeated batches in the four reactors, meaning downtime needed to be kept to a minimum.

A further modification was suggested by Silverson, to overcome potential problems due to height restrictions in the client's mixing area. The mixer was mounted onto a stainless-steel plate rather than a standard skid so the mixer could be installed as close to the floor as possible.

If you’d like to discuss how Silverson can help with your mixing application, please contact [email protected]

- Read less

Published by Silverson Machines on Apr 11, 2022

Silverson Machines

www.silverson.com

E: [email protected]

T: 413-525-4825

Address

355 Chestnut St

East Longmeadow, MA

01028

United States

Show map

Visit our profile