FMX50 produces vegetal glue to replace traditional chemical glue in chipboard and wood paneling

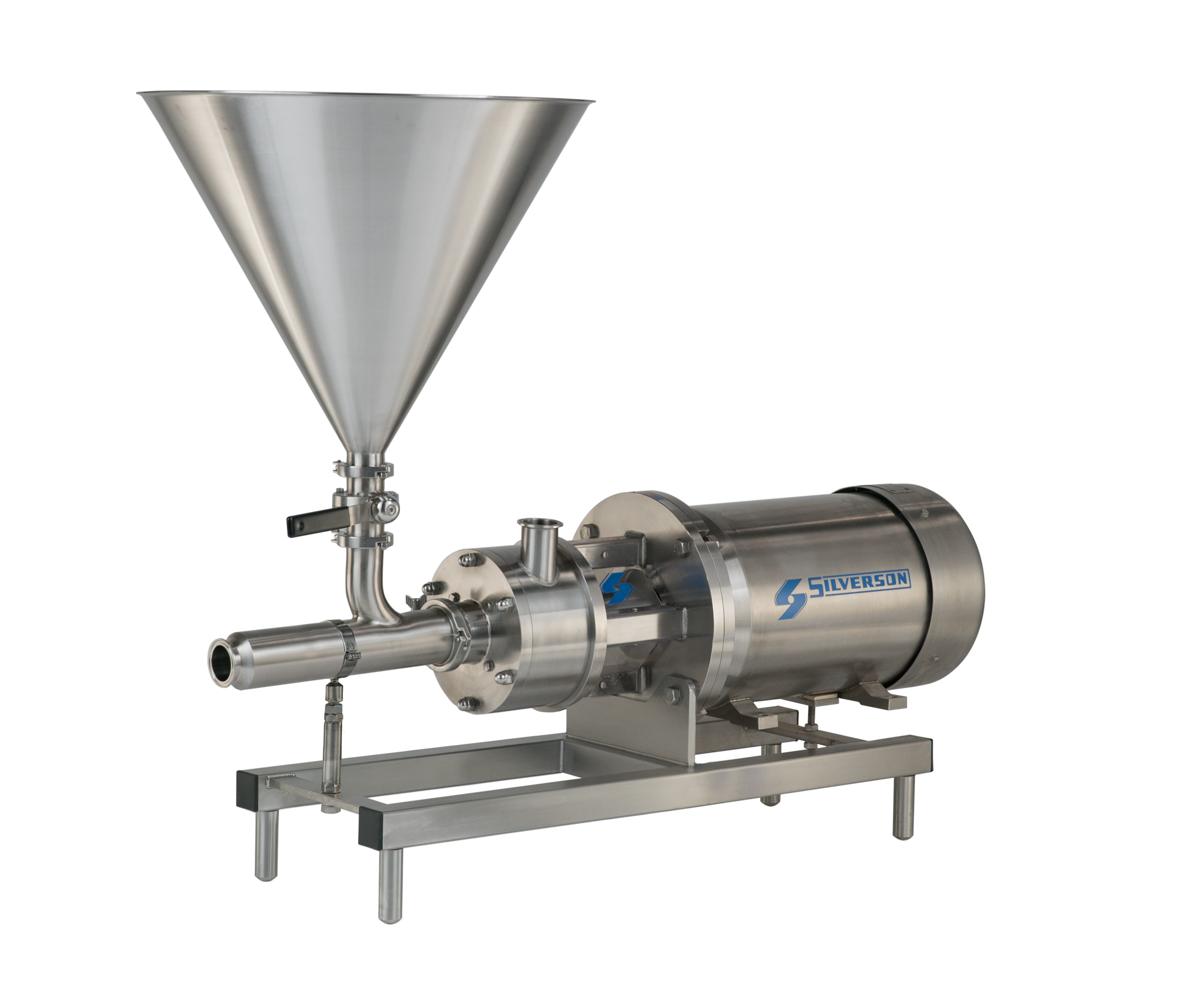

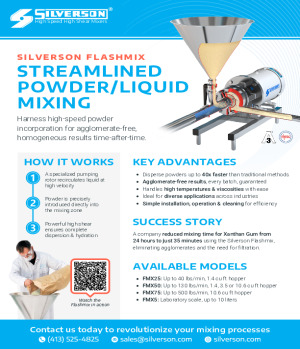

A Silverson Flashmix FMX50 has been sold to a company specializing in the development of viable alternatives to fossil-based products by using new techniques to create renewable raw materials from vegetable proteins.

A Flashmix FMX50 has been sold to a company specializing in the development of viable alternatives to fossil-based products by using new techniques to create renewable raw materials from vegetable proteins.

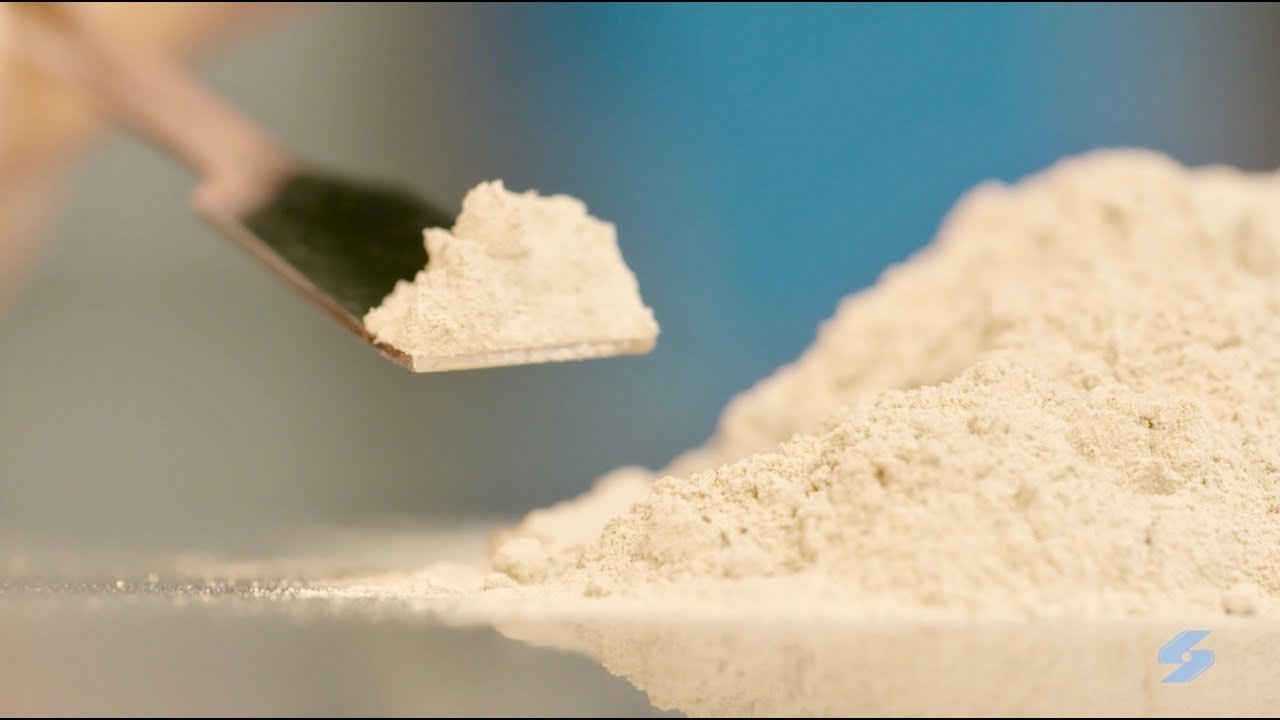

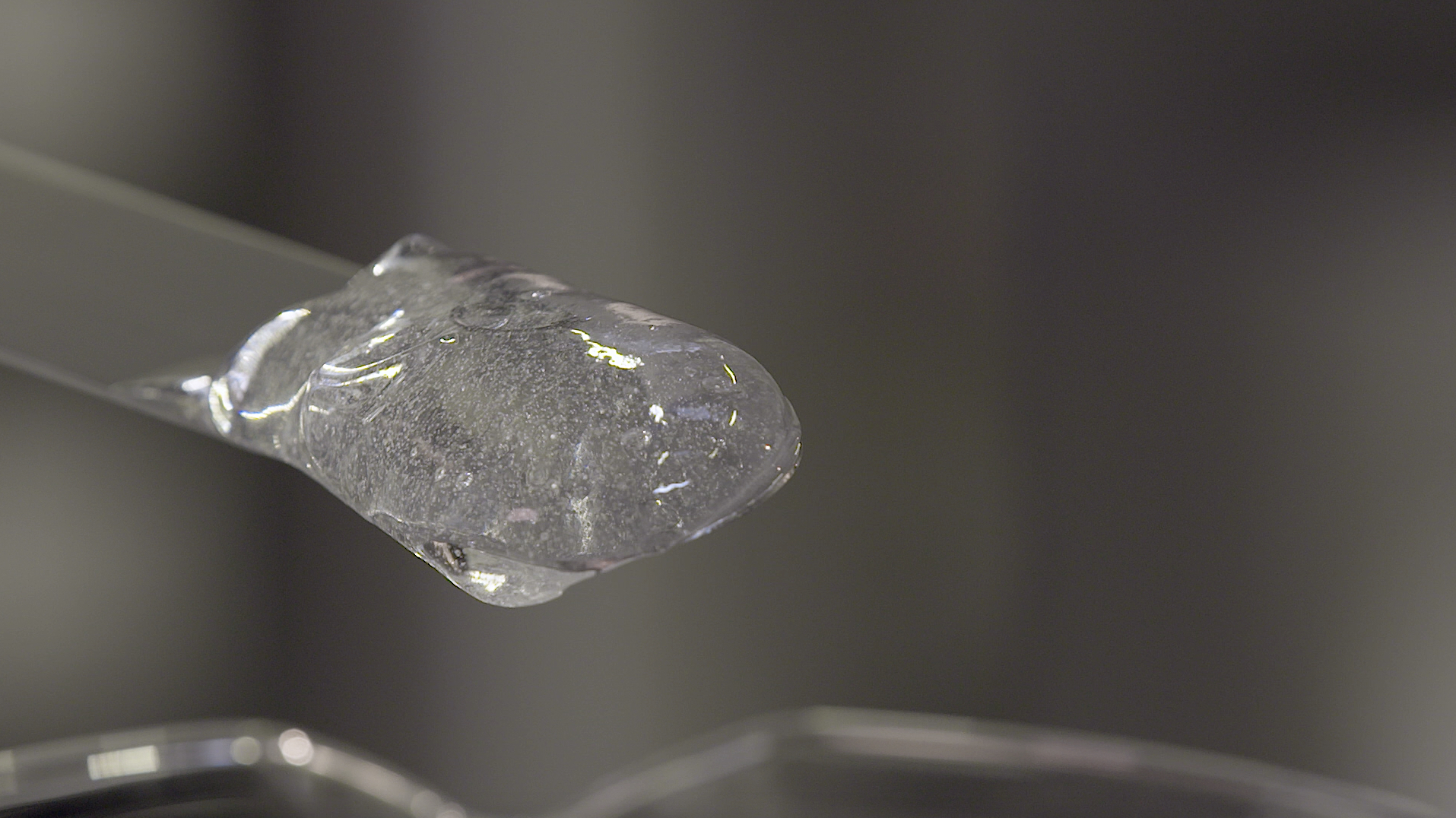

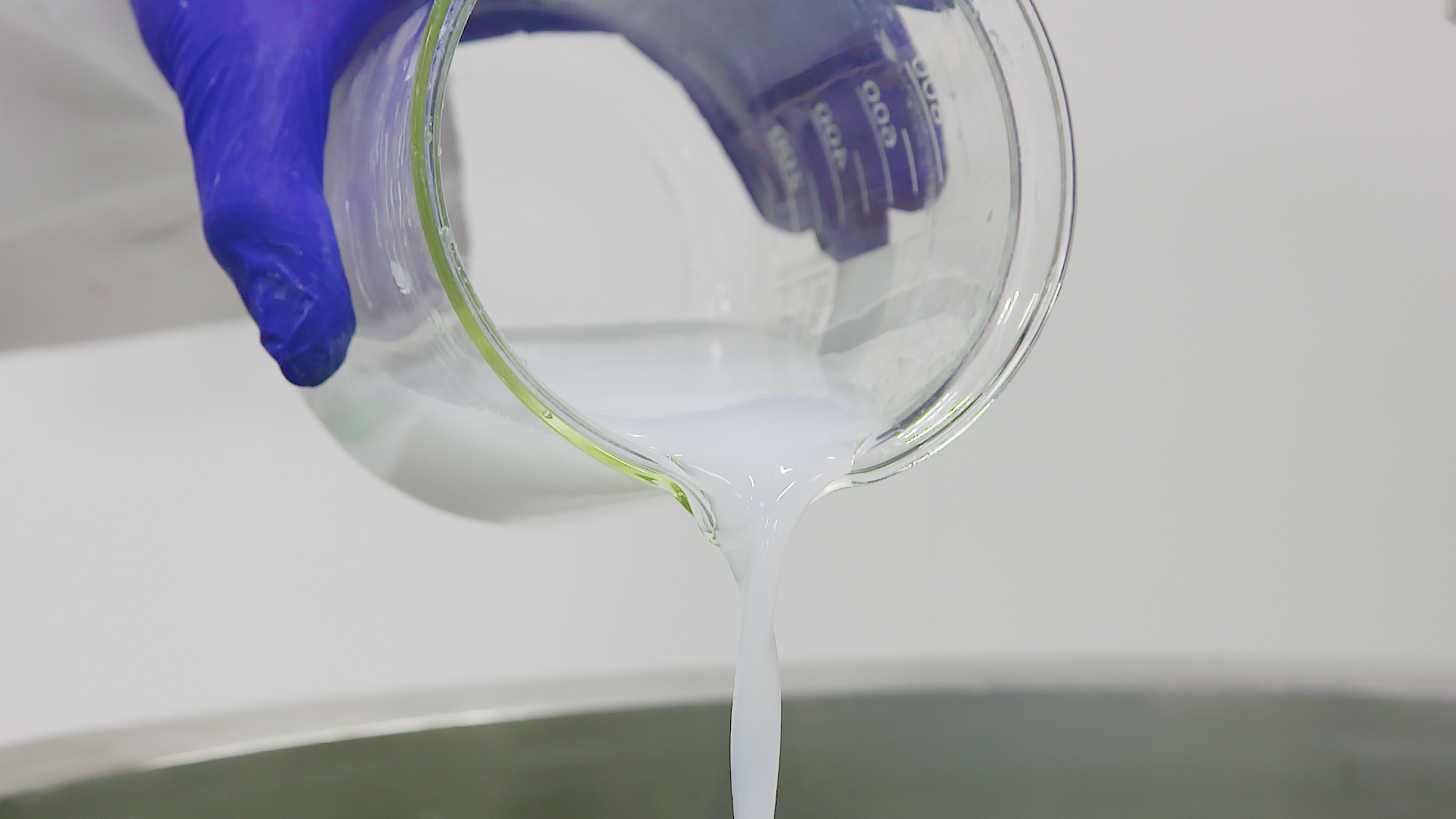

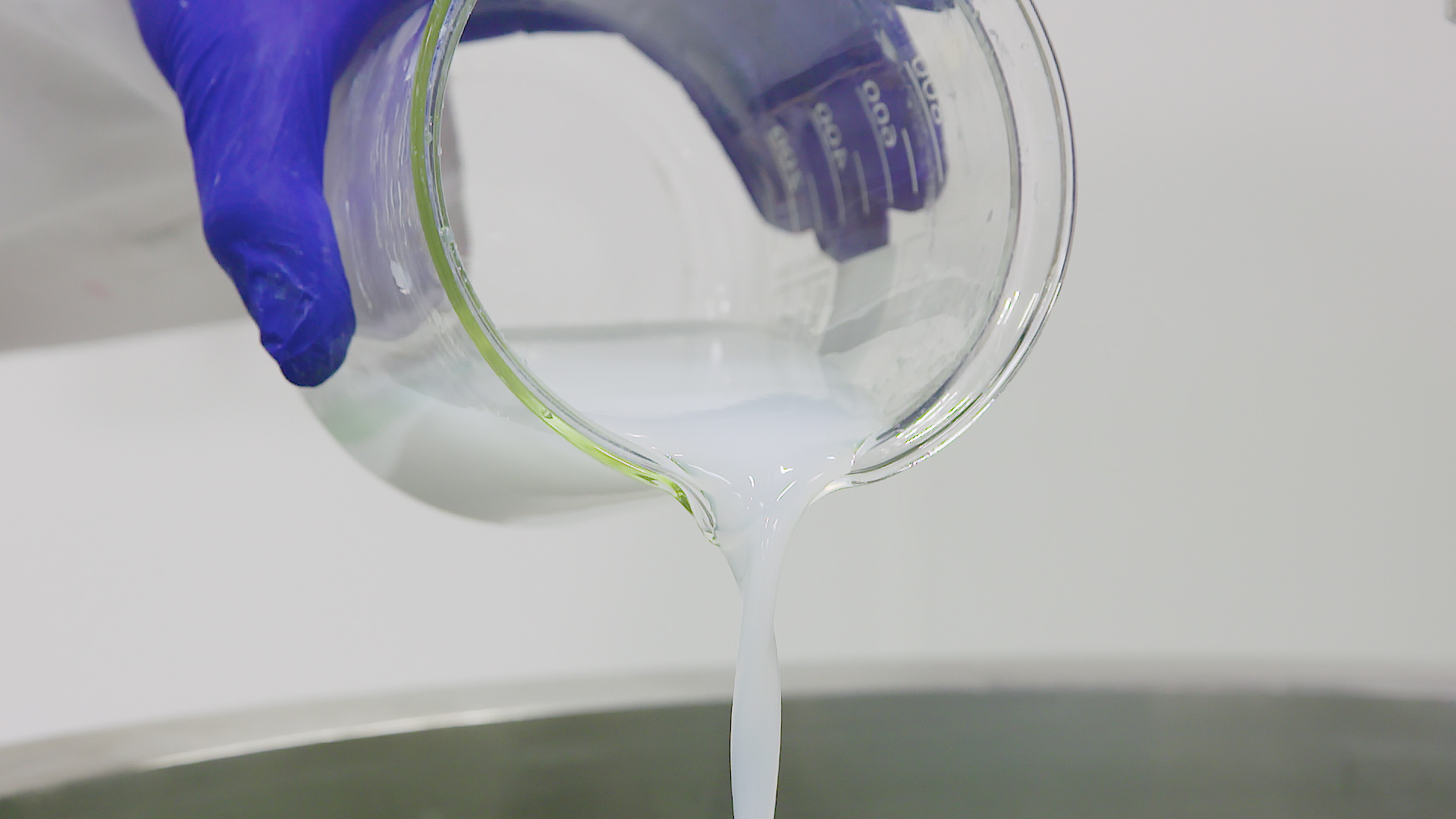

The FMX50 will be involved in part of a process to manufacture vegetable glues to replace traditional chemical glues for chipboard and wood panels. The FMX will be used for mixing 25% vegetal proteins into room temperature water in a 2T tank. The vegetal protein comes in fine particle powder form and is made from 'residual oilcakes' the by-product of the vegetable oil-making process. The vegetal protein in this application uses the by-product of the rapeseeds used for making Colza oil, helping to minimize waste in the vegetable oil industry.

The final viscosity of the powder and water measured around 1000 - 1500 cps, but the liquid was very sticky so after each batch, a cleaning phase using hot water via spray balls in the tank was needed. Trials were run at Silverson to validate the effectiveness of the CIP system and to test the powder incorporation capabilities before the company invested in Flashmix.

The Flashmix was set up with a CIP loop and a 130-gallon vessel with an in-tank agitator. 95 gallons of water was charged into the vessel, then 90kg of powdered protein was incorporated in 1 minute 30 seconds with no problems. Before adding more powder, the CIP was used to test its effectiveness.

After 5 minutes an additional 30kg of powder was added to increase the total solid dispersion to 25% the company wanted. This took 45 seconds to incorporate, again with no problems. The Flashmix was then used to discharge the vessel.

The Flashmix succeeded in minimizing foam, which they ...

+ Read more

After 5 minutes an additional 30kg of powder was added to increase the total solid dispersion to 25% the company wanted. This took 45 seconds to incorporate, again with no problems. The Flashmix was then used to discharge the vessel.

The Flashmix succeeded in minimizing foam, which they had previously had an issue with, and producing a homogeneous mix in a single pass, exactly what the company wanted for the next stage of the process. When the mixer was disassembled they were also pleased to see that there was no powder remaining in or clogging the pipes or hopper.

As a result of the trial, the company purchased the FMX50 to become part of a complete mixing unit installed in their new innovation center dedicated to renewable chemistry and promoting new ways of developing vegetable proteins.

- Read less

Published by Silverson Machines on Mar 28, 2022

Silverson Machines

www.silverson.com

E: [email protected]

T: 413-525-4825

Address

355 Chestnut St

East Longmeadow, MA

01028

United States

Show map

Visit our profile