Dispersion of Bentonite with Silverson High Shear Mixers

How can Silverson Machines help with mixing Bentonite?

Bentonite is a naturally occuring aluminium silicate clay which can take up several times its own weight of water to form a highly thixotropic colloidal suspension or gel. One of the principal applications for bentonite is in drilling muds, however, it is widely used as a suspending and stabilizing agent and as an adsorbent or clarifying agent, in many industries.

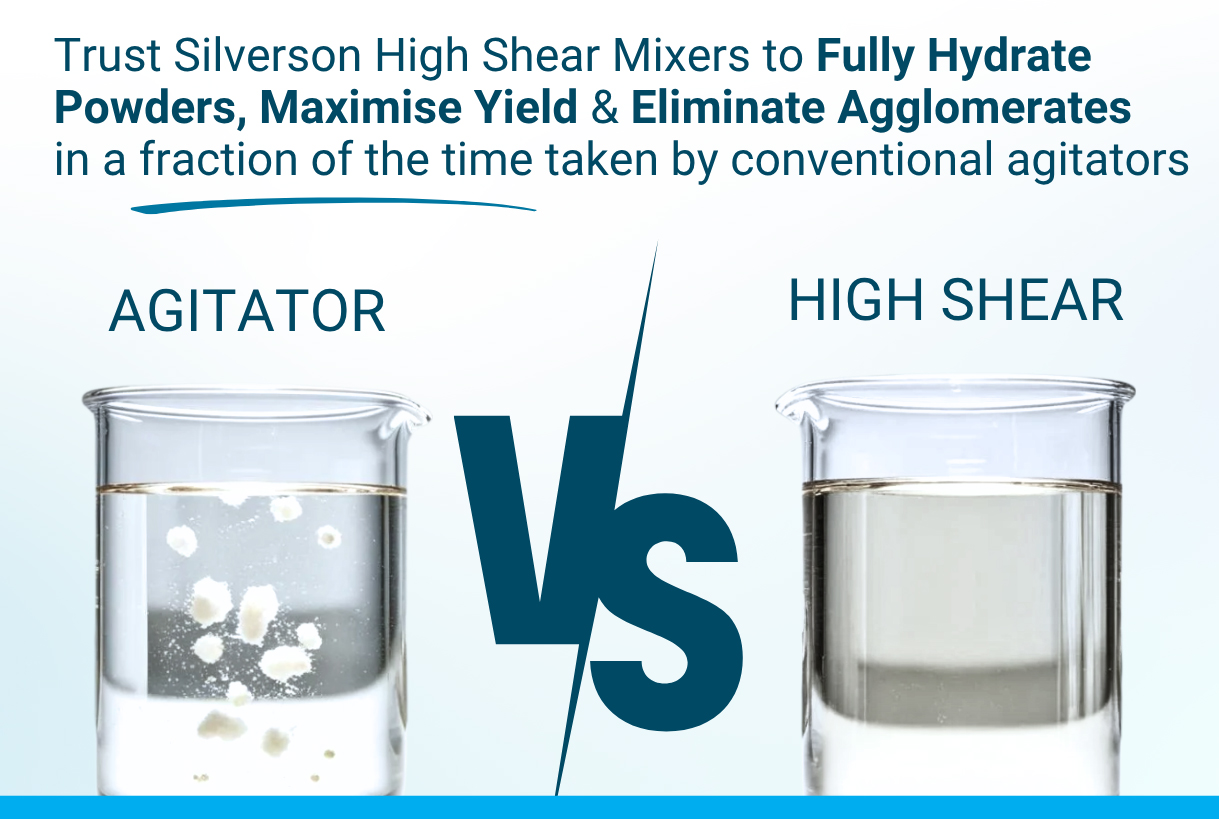

Dispersing Bentonite with conventional mixing equipment, such as agitators and stirrers can be difficult and several problems can be encountered during the mixing process. For example, long mixing cycles are required to obtain uniform dispersion and complete hydration. This is due to the powder tending to agglomerate when added to water. The washing action of conventional mixers cannot break down the agglomerates effectively, as they do not produce sufficient shear. As such, sometimes additional equipment such as colloid mills may be required to obtain the required particle size and activate the gelling effect.

How can Silverson Machines help with mixing Bentonite?

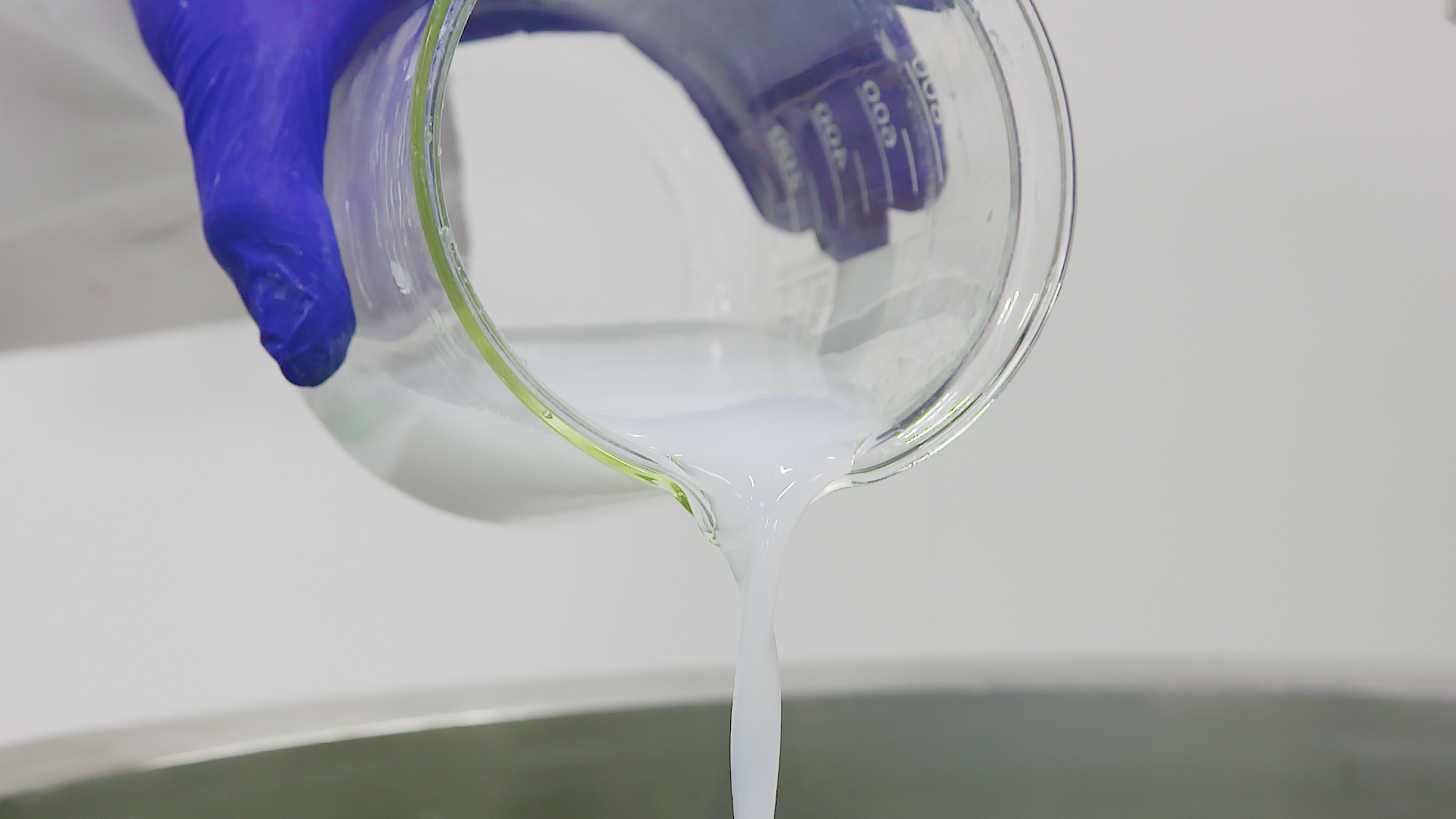

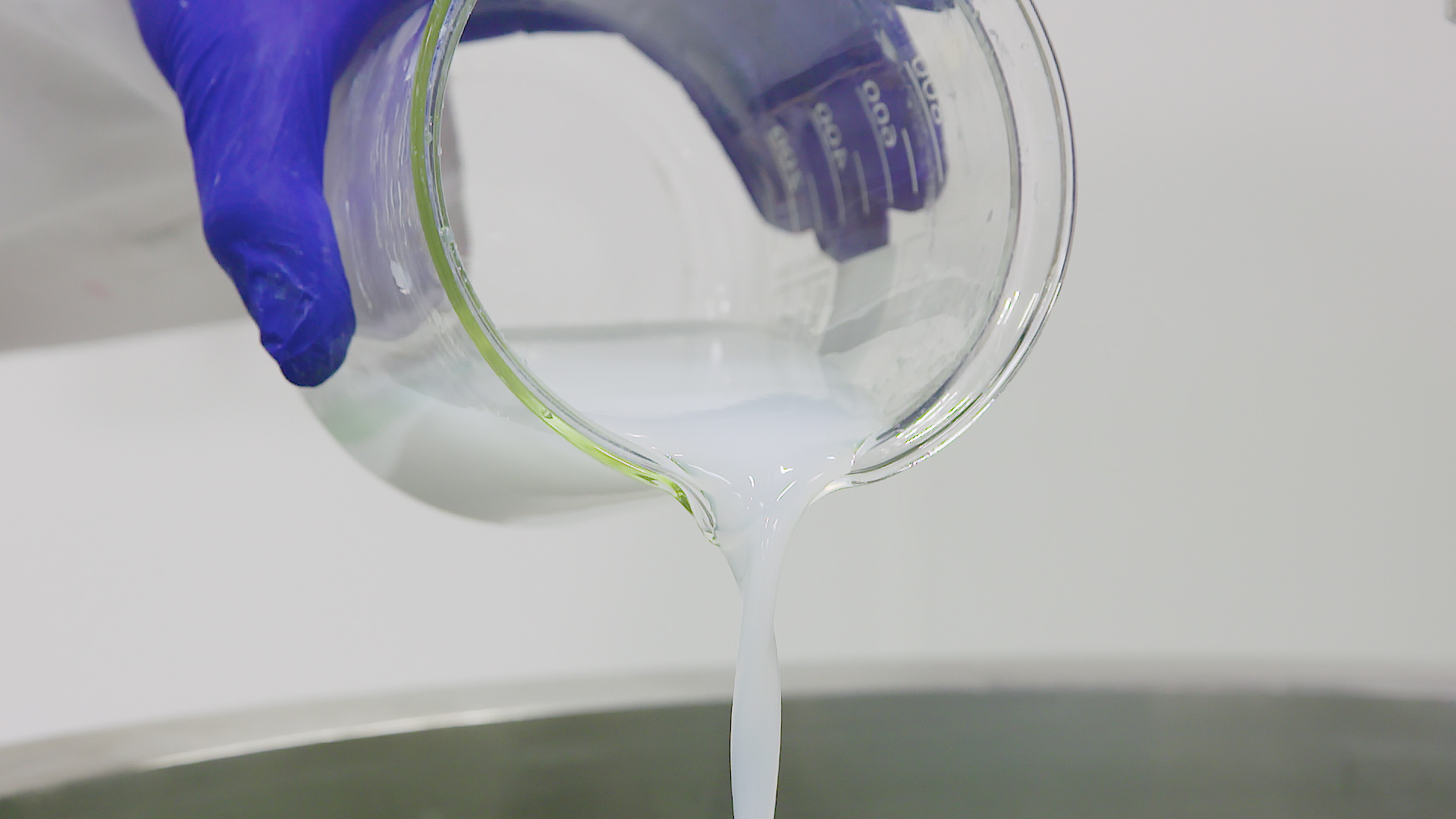

The above problems can be overcome using a high shear mixer. When the mixer is started the high speed rotation of the rotor creates a powerful suction which draws the water and clay up from the base of the vessel into the workhead, rapidly dispersing the powder.

Centrifugal force ...

+ Read more

The above problems can be overcome using a high shear mixer. When the mixer is started the high speed rotation of the rotor creates a powerful suction which draws the water and clay up from the base of the vessel into the workhead, rapidly dispersing the powder.

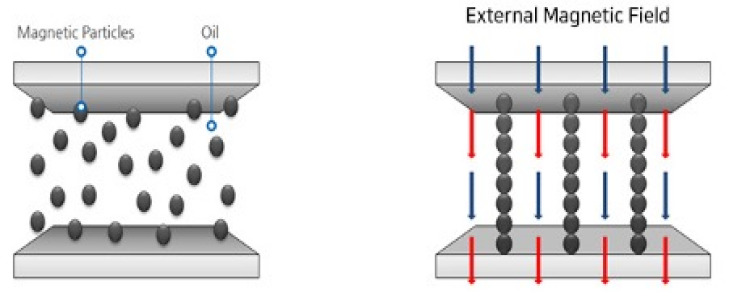

Centrifugal force drives the water and bentonite particles towards the periphery of the workhead. The particles are deagglomerated in the gap between the rotor and stator before being forced out through the stator and projected back into the mix at great velocity. Fresh material is simultaneously drawn into the workhead.

After a short mixing time, all of the material has passed through the workhead several times, activating the full yield and accelerating the hydration process.

The shorter processing time required to form a stable suspension reduces wear and therefore maintenance and spare part costs.

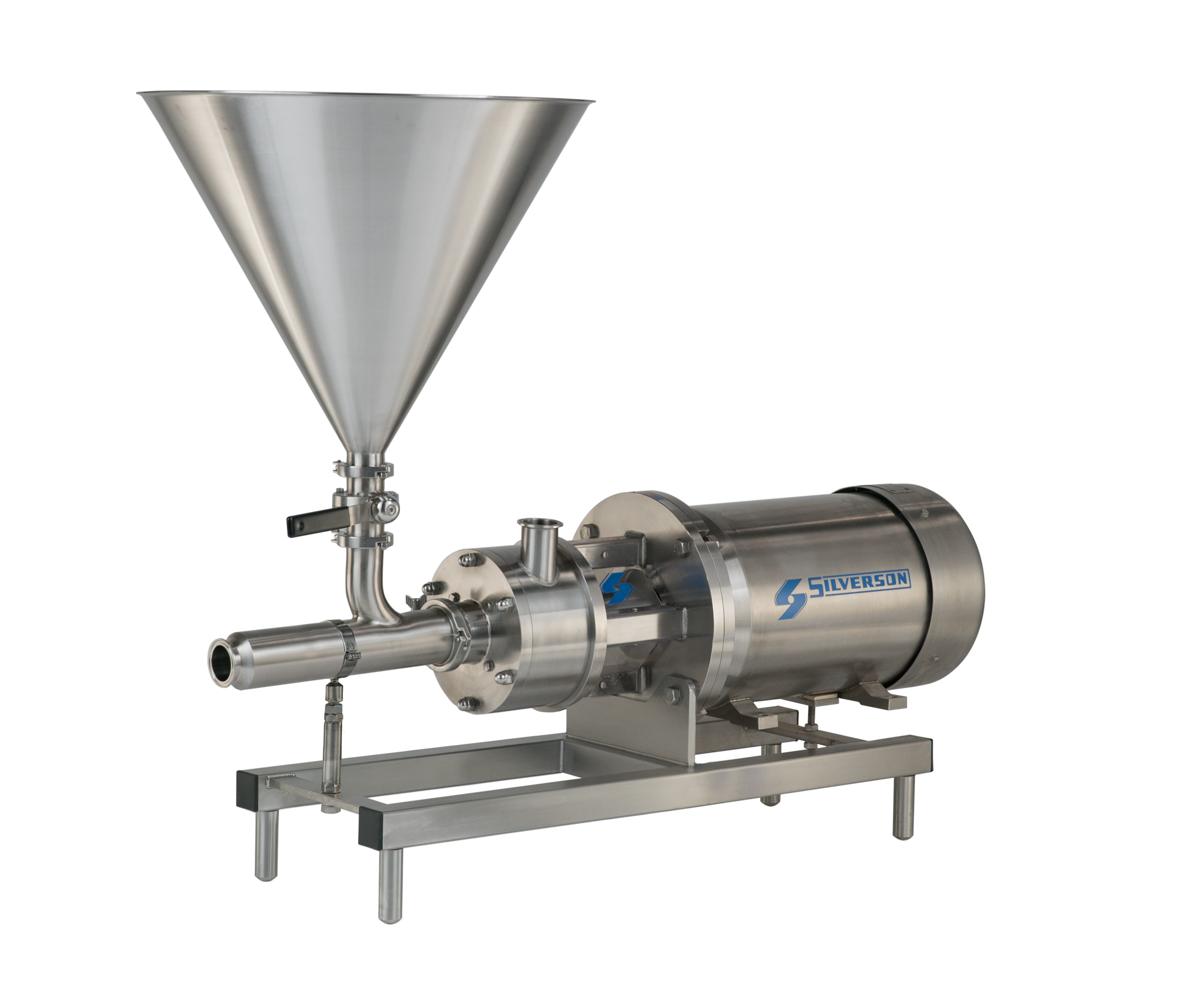

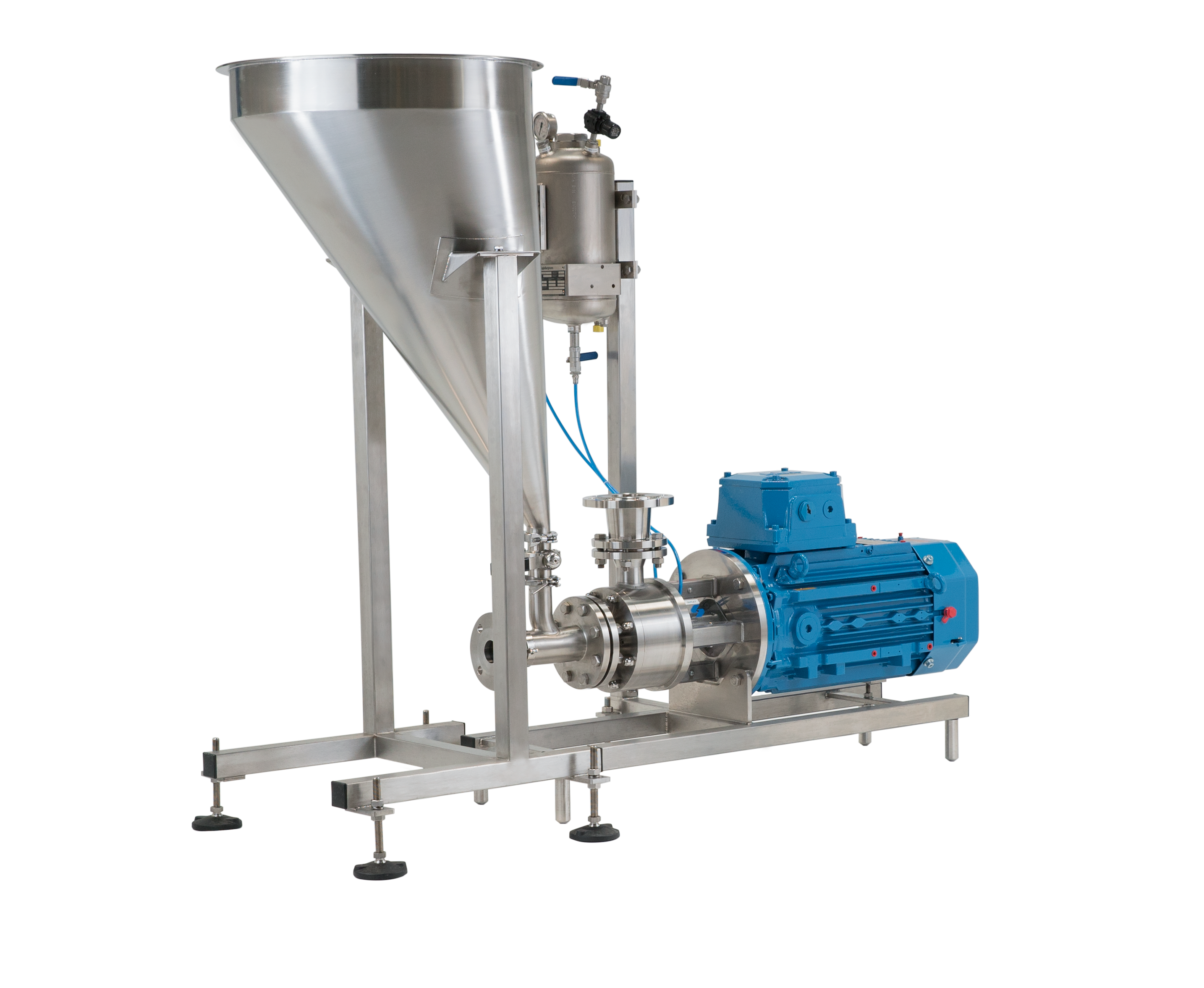

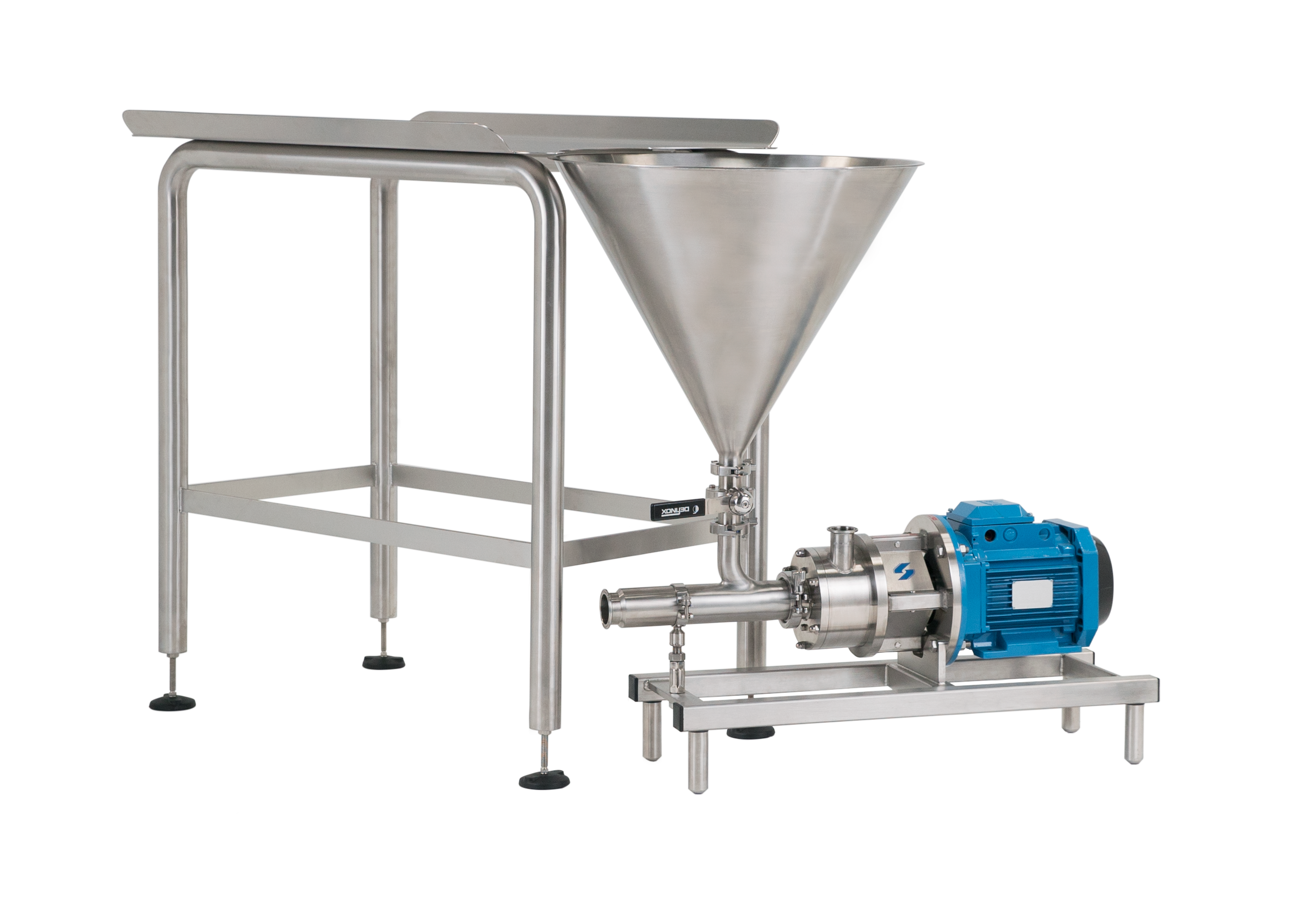

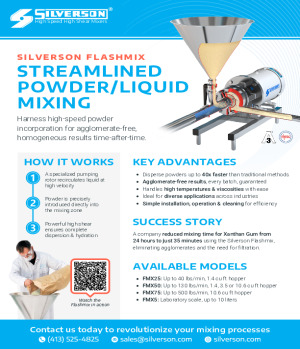

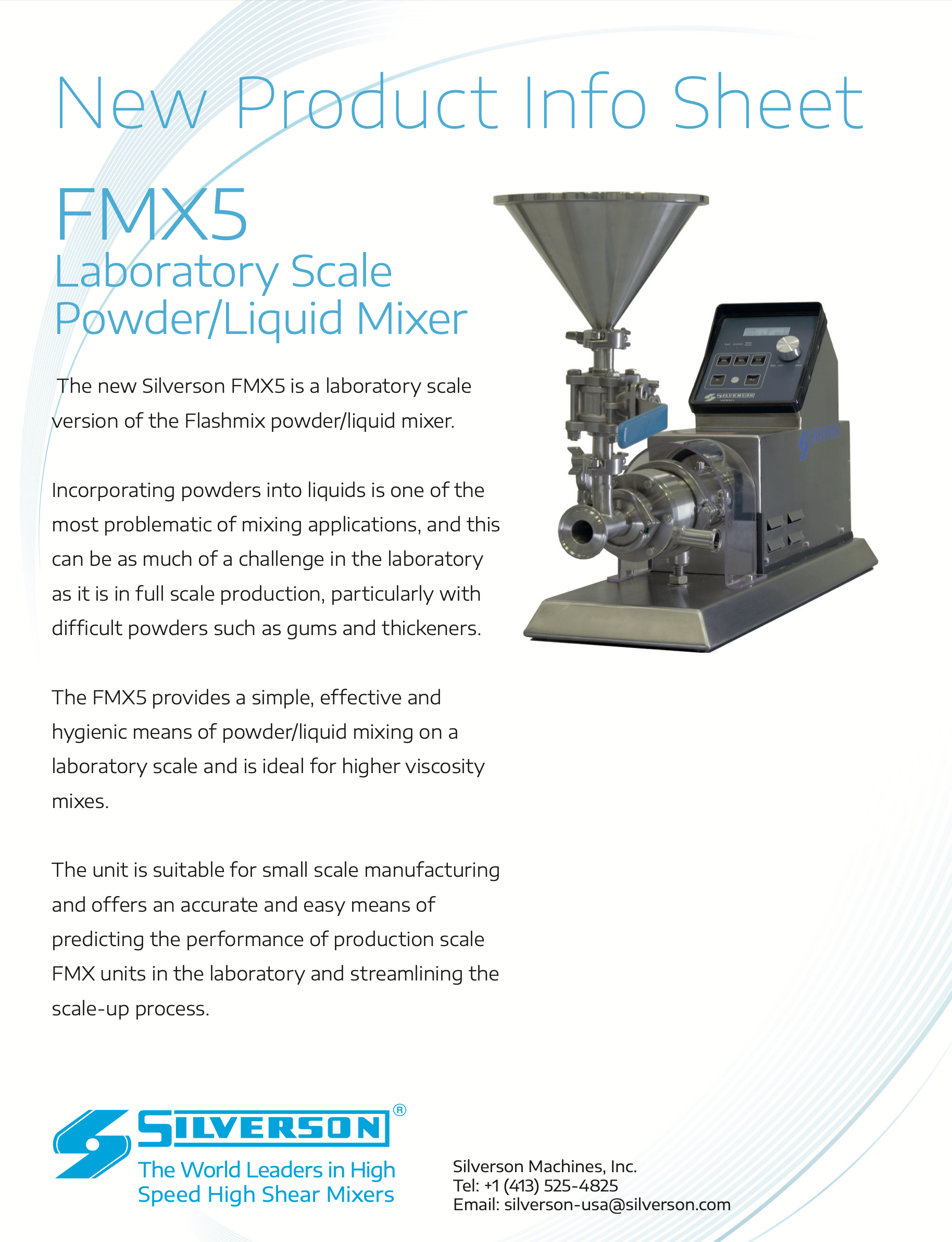

For this application, Silverson offer several mixers, including in-tank Batch mixers, In-Line mixers and the Silverson Flashmix, depending on the batch size.

You can find out more by watching the Silverson 'How to' video on dispersing Bentonite, or read the application report on the Silverson website.

If you want to discuss your bentonite, or any other powder/liquid mixing application, get in touch with us today: [email protected]

- Read less

Published by Silverson Machines on Jan 02, 2024

Silverson Machines

www.silverson.com

E: [email protected]

T: 413-525-4825

Address

355 Chestnut St

East Longmeadow, MA

01028

United States

Show map

Visit our profile