Eco-Smart Sugar Sifters: 65% Less Energy Consumption

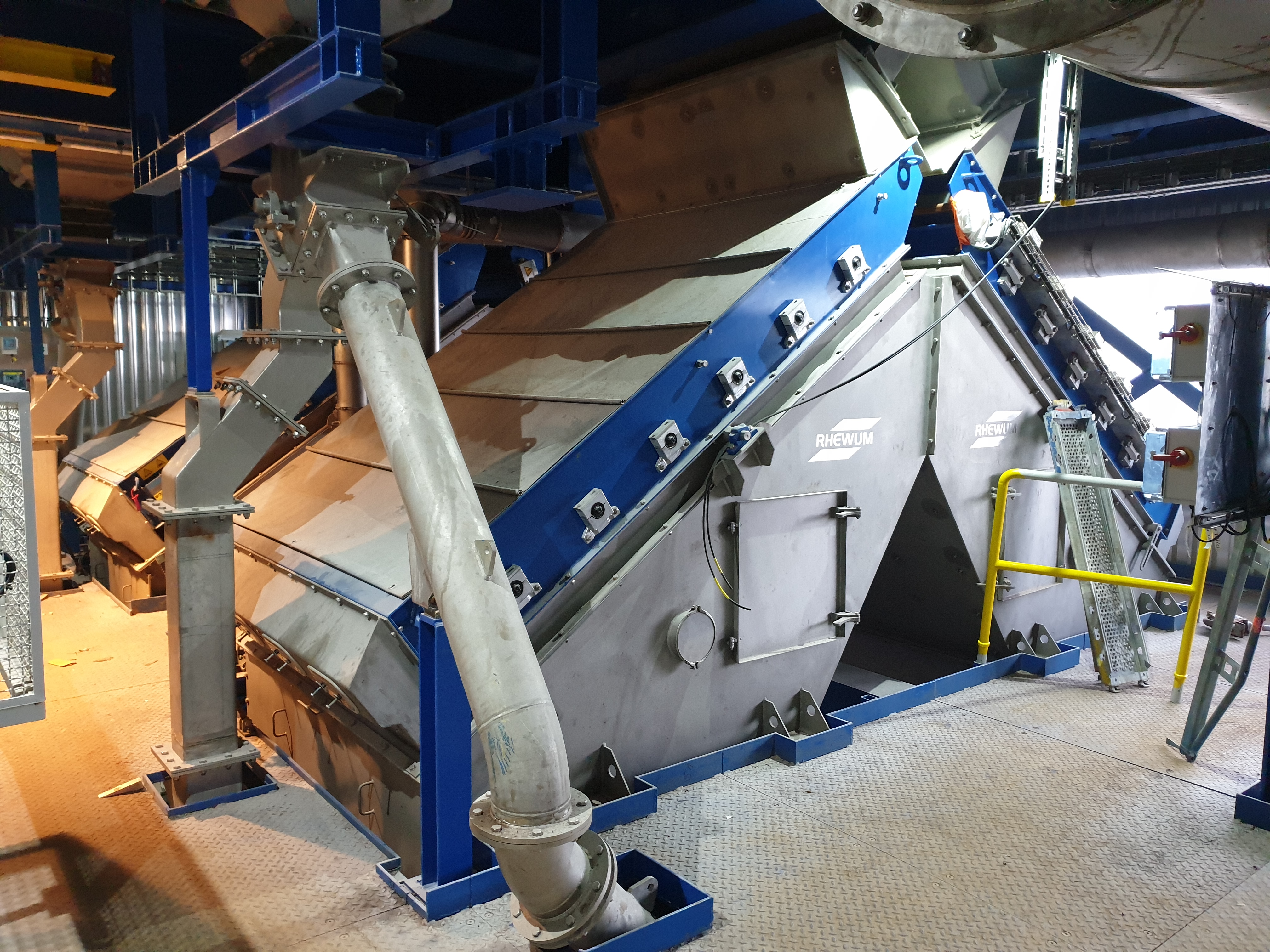

Sugar refining facilities are achieving remarkable energy savings through direct-vibration screening technology, reducing power consumption by up to 65% while improving product quality and operational efficiency.

Industrial sugar processing facilities face mounting pressure to reduce operational costs while meeting strict quality requirements. Direct-excited screening technology has proven its effectiveness in addressing both challenges, delivering substantial energy savings alongside improved screening performance.

The Challenge with Traditional Screening Methods

Conventional screening systems in sugar refining typically rely on linear motion "sizers" or gyratory movement screens. These traditional approaches face several limitations that impact both efficiency and sustainability:

- Linear Motion "Sizers" operate at steep inclinations (20°-45°) with high transportation speeds of 0.5-1.3 m/s. While they offer high capacity due to fast material flow, they suffer from significant clogging tendencies and low screening efficiency, particularly with fine meshes.

- Gyratory Movement Screens use inclinations of 5°-15° and rely on bouncing balls for anti-clogging. However, their effectiveness is limited because balls only impact specific zones, leading to fast clogging and reduced throughput.

Direct-Vibration Technology: A Game-Changing Approach

Direct-excited screening technology addresses these challenges through a fundamentally different approach. Instead of vibrating the entire machine, this technology applies high-frequency vibration directly to the s...

+ Read more

Direct-Vibration Technology: A Game-Changing Approach

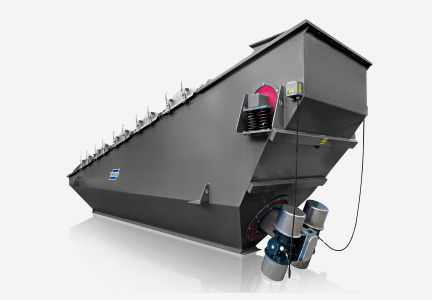

Direct-excited screening technology addresses these challenges through a fundamentally different approach. Instead of vibrating the entire machine, this technology applies high-frequency vibration directly to the screen mesh through electromagnetic vibrating heads or small out-of-balance motors.

Key Technical Features:

- Accelerations up to 15g applied directly to screen mesh

- Material thrown perpendicular from screen surface

- Static housing design eliminates structural vibration

- Automatic cleaning cycles with maximum force application

Quantified Performance Benefits

A comprehensive case study involving 300 t/h crystallized sugar processing reveals impressive performance metrics:

- Capacity Efficiency: Two direct-excited machines can handle the same throughput that requires eight traditional "sizer" screens, representing a 75% reduction in equipment requirements.

- Energy Consumption: Power requirements drop from 72 kW (traditional) to 25.6 kW (direct-excited), achieving approximately 2.8 times better energy efficiency.

- Product Quality: The technology consistently achieves product purities exceeding 92%, surpassing typical industry requirements of 90%.

Environmental and Economic Impact

The sustainability benefits extend beyond energy savings:

- Reduced Moving Mass: Traditional systems require 28 tons of moving mass compared to just 5.6 tons for direct-vibration systems, resulting in 20 times less dynamic load transmission to building structures.

- Annual Cost Savings: Based on average European electricity costs, facilities can expect annual energy savings of approximately $3,100, with greater potential in regions with higher electricity rates.

- Operational Advantages: The static housing design enables dust-tight construction, fixed connections without compensators, and reduced maintenance requirements due to fewer machines needed.

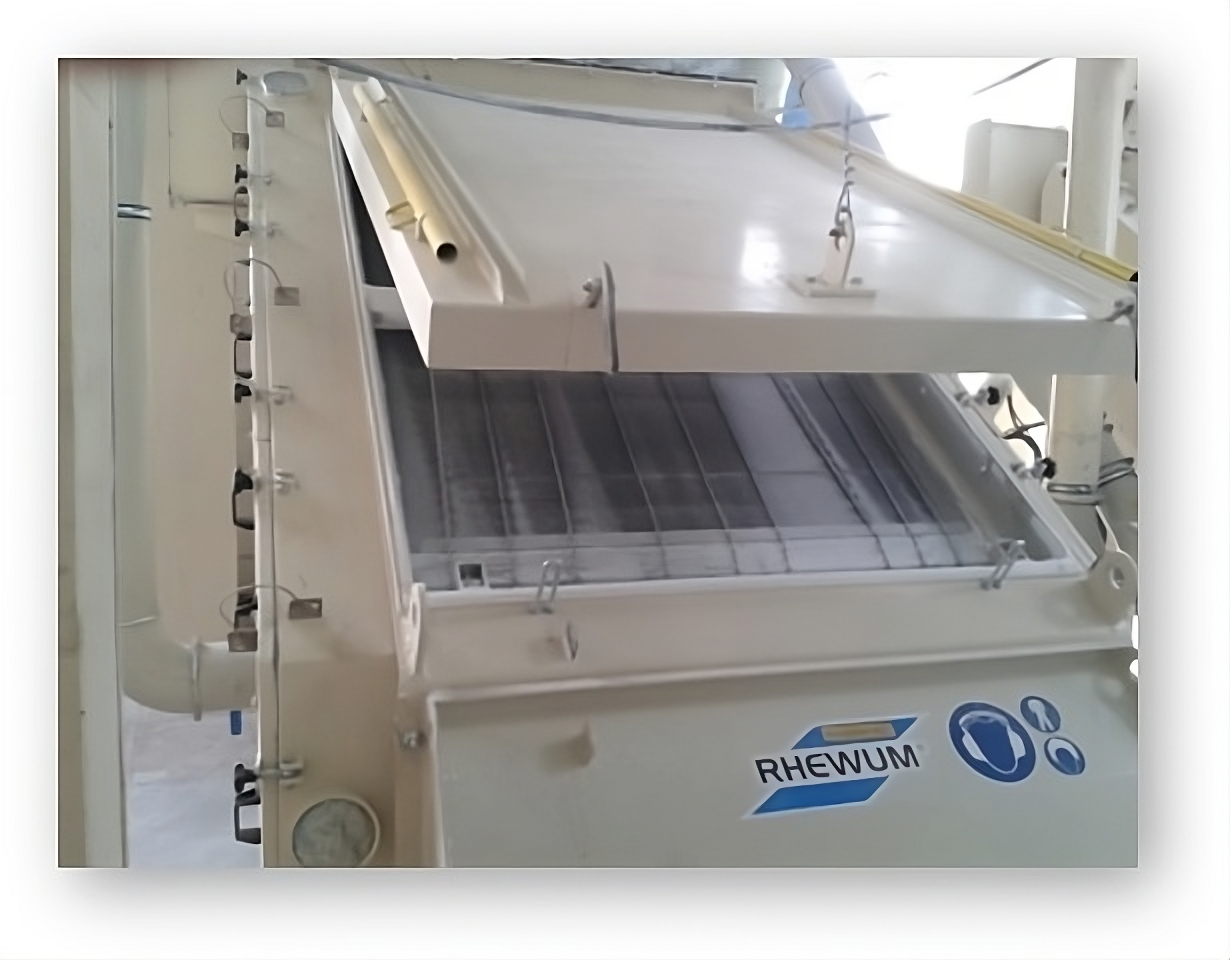

Superior Anti-Clogging Performance

One of the most significant operational improvements is the enhanced anti-clogging capability. The high-frequency direct excitation prevents mesh clogging more effectively than traditional bouncing ball systems. The technology can automatically increase forces to maximum levels during cleaning cycles, ensuring consistent throughput even with challenging materials.

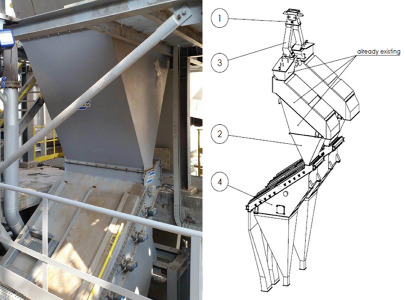

Implementation Considerations

When evaluating direct-excited screening technology, facilities should consider:

- Footprint Optimization: Fewer machines required for equivalent capacity

- Structural Requirements: Reduced foundation and support structure needs

- Integration Flexibility: Fixed connections possible without vibration compensators

- Maintenance Scheduling: Simplified maintenance due to fewer units and static housing design

Industry Applications Beyond Sugar

While the case study focuses on sugar refining, the technology's benefits extend to various industries requiring precise particle separation:

- Chemical processing

- Food and beverage production

- Pharmaceutical manufacturing

- Fertilizer production

- Building materials processing

- Mineral processing

Future Outlook

As industries face increasing pressure to reduce environmental impact while maintaining productivity, direct-excited screening technology represents a practical solution that delivers measurable results. The combination of energy efficiency, improved product quality, and reduced operational complexity makes this technology particularly attractive for facilities planning equipment upgrades or new installations.

The documented 65% energy reduction, combined with superior product quality and reduced maintenance requirements, positions direct-excited screening as a key technology for sustainable industrial operations.

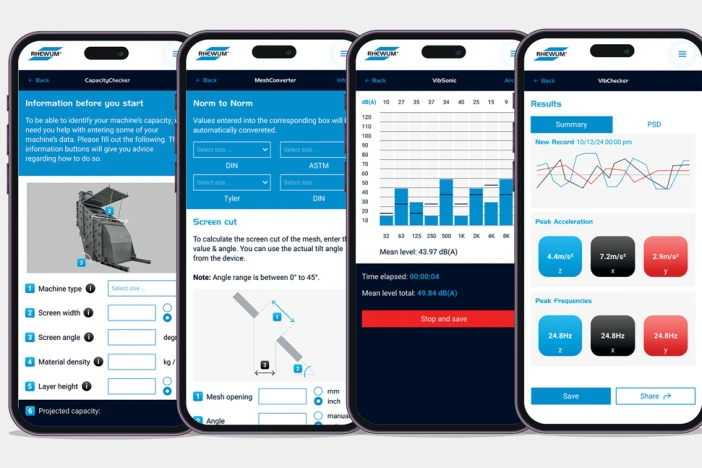

Want to see how direct-excited screening technology can boost your bottom line?

Download the complete technical white paper from our website for detailed specifications, case study data, and implementation guidelines.

- Read less

Published by RHEWUM America Inc. on Sep 15, 2025

RHEWUM America Inc.

www.rhewum.us

E: [email protected]

T 888 474 3986 (888 4RHEWUM)

954 990 8847

Address

10424 W State Rd 84

Suite 7

Davie, FL

33324

United States

Show map

Visit our profile