Boosting Potash Output by 20-30%: How to Fix Your Biggest Production Bottleneck

Most potash plants are limited by screening bottlenecks, not raw materials—strategic upgrades typically deliver 20-30% capacity gains with payback under one year. A real MOP facility boosted throughput from 400 t/h to 696 t/h by replacing four screens with two RHEWUM RHEduo® units, achieving 77.6% product purity while eliminating maintenance headaches. Right-sizing screens and fixing feed distribution beats major rebuilds for fast ROI and long-term flexibility.

Potash

demand keeps climbing while supply stays locked into a handful of regions that

could get hit by political disruptions any time. For most plants, the quickest

way to boost capacity and nail down quality isn't some massive overhaul—it's

fixing the screening bottlenecks that are choking your compaction and

granulation circuits.

Why

screening fixes work fast

Here's the

thing: screening is what's actually limiting most potash lines, especially in

compaction/granulation and final sizing. Fix that constraint and you

immediately see higher throughput and more stable product quality. The best

part? You're mostly talking about right-sizing screens and getting the feed

distribution dialed in—not tearing apart your whole plant. Most brownfield

upgrades get done in about six months and typically unlock 10–20% more

production. When you go with purpose-built machines for the key separations,

plants commonly see 20–30% capacity gains (that's often +100–150 t/h), and the

payback usually hits in under a year if you can move that extra product.

What's

actually holding you back

Here's what

we see killing throughput in potash plants:

- Undersized

or maxed-out screens

in compaction and granulation create the bottleneck; when material doesn't get

distributed evenly across the decks, your separation efficiency tanks and

recirculation goes through the roof.

- Maintenance

nightmares like

manual screen cleaning that eats up 8 hours a month, mechanical knockers that

need swapping every three months because of the high temps, and product screen

conveyor belts that have to be replaced roughly every three weeks—and dust

makes all of this worse.

- Too much

recirculation of

oversize and fines drives up energy costs in the compaction–crushing–screening

loop and messes with stability downstream.

Real-world results: MOP granule plant gets 75% more throughput

We ran a comprehensive study at a muriate of potash (MOP) granule facility to see what strategic screening upgrades could actually deliver. The goal was pushing their potassium chloride (KCl) compaction...

+ Read more

Real-world results: MOP granule plant gets 75% more throughput

We ran a comprehensive study at a muriate of potash (MOP) granule facility to see what strategic screening upgrades could actually deliver. The goal was pushing their potassium chloride (KCl) compaction and screening line from 400 t/h up to 696 t/h (with 900 t/h design capacity).

What they were dealing with: Four third-party product screens running 100 t/h each, but getting hammered by operational problems:

- Manual screen cleaning sucking up 8 hours every month

- Mechanical knockers dying every three months from high-temp wear

- Feed conveyor belts needing replacement every three weeks

- Uneven feed distribution across screens killing efficiency

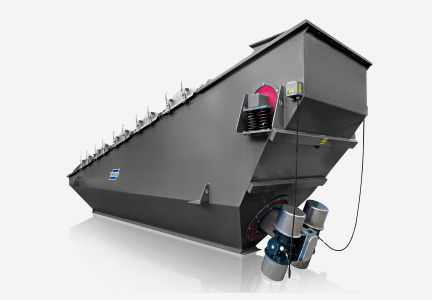

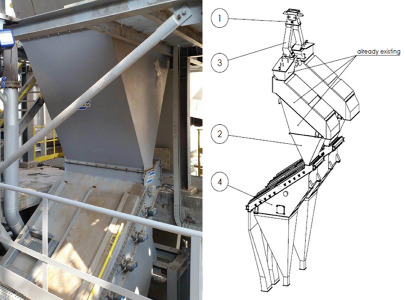

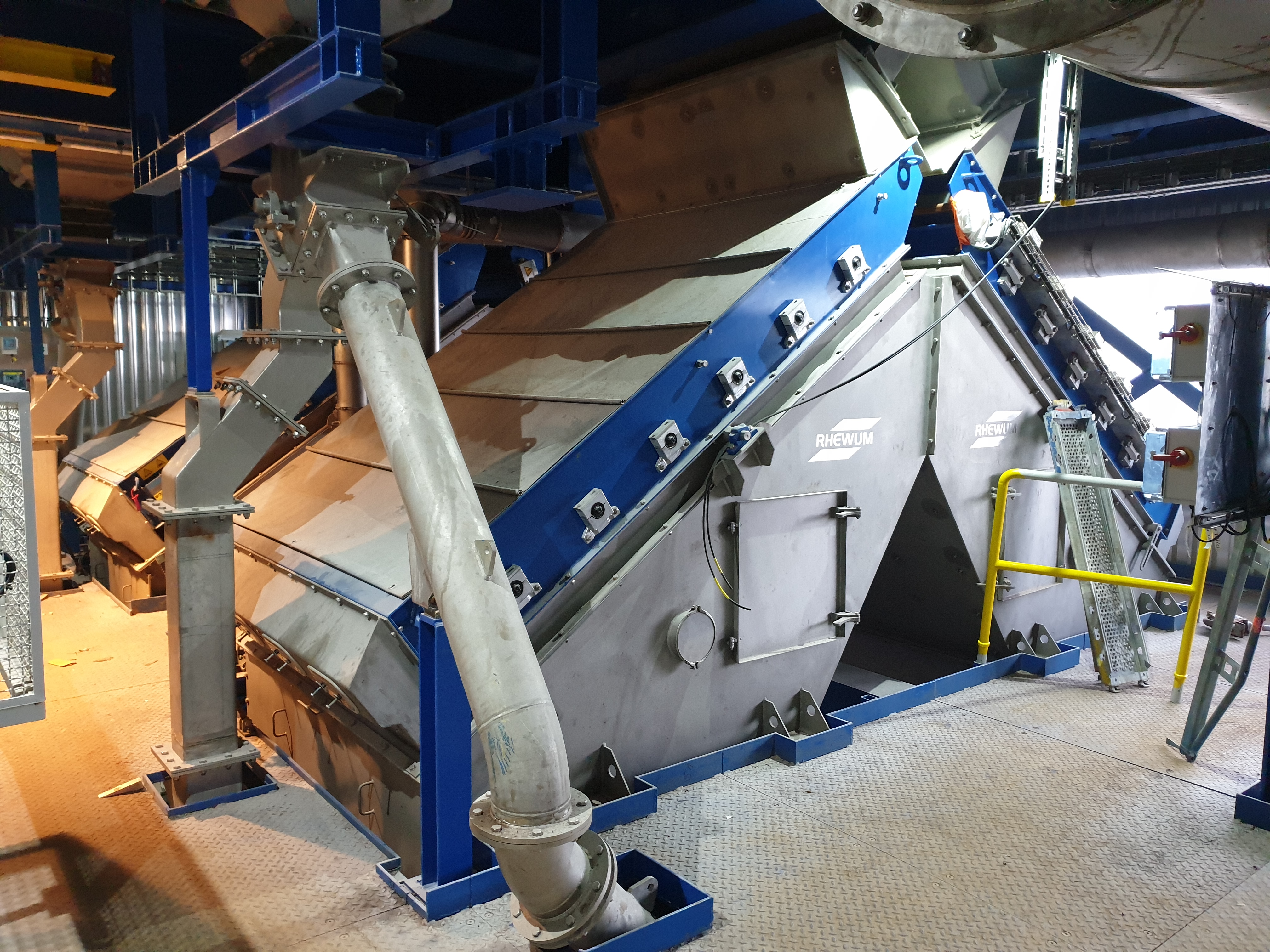

The fix: RHEWUM swapped out those four screens for two RHEduo® triple-deck machines, each handling 348 t/h feed capacity (450 t/h design). We managed material distribution through RHEmid feeders and custom distribution chutes to keep loading consistent.

The numbers: RHEduo® system trials delivered solid results:

- 4-2 mm fraction: 77.6% product purity with 90.57% yield

- Final product output: roughly 155-138 t/h in the target 4-2 mm range

- Combined system throughput: 696 t/h (900 t/h design)

Why purpose-built equipment makes the difference

The RHEduo® system tackles the stuff that kills potash operations:

Keeps things running:

- Steep machine angle prevents screen flooding, cutting unplanned downtime

- Static housing lets you use fixed flange connections—no more compensator replacements

- External drives handle product temps up to 450°C

- Low-vibration design means you don't need anti-vibration frames

Cuts maintenance headaches:

- Integrated chain-based screen cleaning ditches those high-maintenance bouncing balls

- Massive reduction in manual cleaning time

- Consistent deblinding without having to swap components all the time

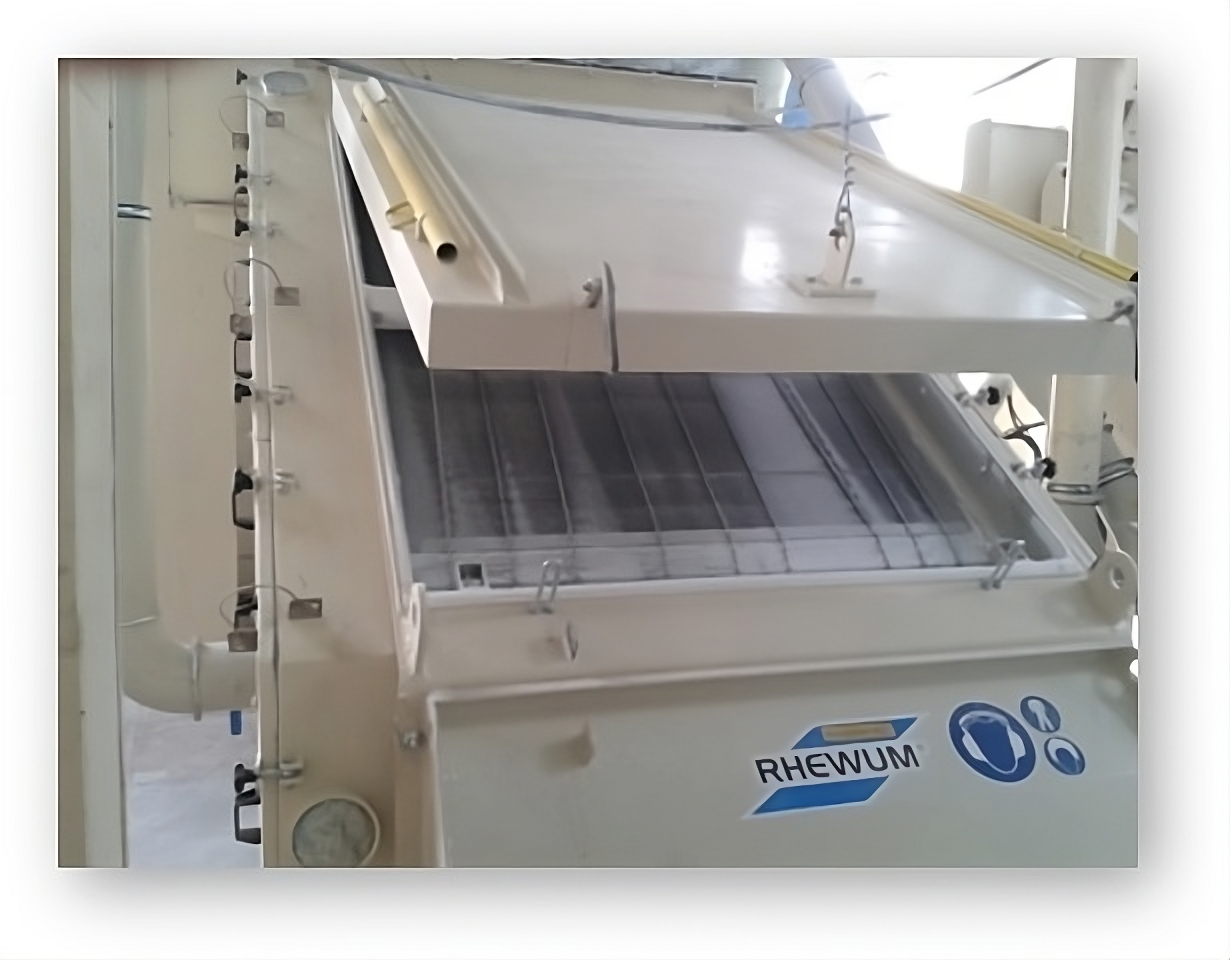

Dust control and product quality

For final product screening, the plant installed a RHEflex® linear vibrating screen built for dust separation, rated at 146 t/h. Trial results showed serious precision:

- <2 mm fraction: 98.6% product purity, 35.31% yield

- 2-4 mm fraction: 78.9% product purity, 99.97% yield

The RHEflex® uses high-frequency linear vibration for tight separations at narrow cut sizes, with compact, modular design that fits into existing layouts without structural reinforcement .

The bottom line: fast payback, long-term gains

Strategic screening upgrades deliver compelling economics: ROI typically comes in under one year per line when you can sell that added capacity. Beyond the immediate throughput boost, operations see fewer downtimes, longer maintenance intervals, lower lifecycle costs, and better ability to respond when the market moves.

In a market getting whipsawed by geopolitics and supply chain disruptions, operational flexibility and throughput agility aren't nice-to-haves—they're must-haves. De-bottlenecking your screening circuit gives you a scalable, cost-effective way to unlock capacity and lock in long-term profitability.Practically speaking, you've got two moves: replace undersized screening machines with properly sized units, or add screening capacity upstream or downstream to take the load off overworked equipment.

Want the full breakdown with data, flowsheets, and equipment specs? Download the complete white paper from our website now.

This article summarizes the white paper "Unlocking Potential: Tackling Bottlenecks in Potash Production" by RHEWUM GmbH. All technical details and performance metrics come from the complete source study.

- Read less

Published by RHEWUM America Inc. on Sep 10, 2025

RHEWUM America Inc.

www.rhewum.us

E: [email protected]

T 888 474 3986 (888 4RHEWUM)

954 990 8847

Address

10424 W State Rd 84

Suite 7

Davie, FL

33324

United States

Show map

Visit our profile