Silicosis Risk: Screeners vs. Sifters on Safety and Energy

Silica dust is a persistent workplace hazard. This article compares sifters with modern screening—showing how direct-excited screens achieve superior separation, lowerenergy demand, and better dust control, despite higher upfront costs.

Silicosis: Why Direct-Excited Screening Improves Safety and Energy

Silicosis is a preventable occupational lung disease caused by inhaling respirable crystalline silica (quartz dust). The tiniest particles reach the alveoli, where they trigger inflammation and permanent scarring. Industries like cement, mining, stone, ceramics, glass, and foundries must keep respirable silica out of workplace air at the source—making your separation technology choice critical for both worker safety and regulatory compliance.

Sifters vs. Screening: The separation and energy compromises

Many production lines still rely on sifters (air classifiers) to separate quartz-bearing fines. While they're often cheaper upfront, two operational issues matter in silica-sensitive applications:

- Lower separation sharpness: Cut curves can widen under varying loads or moisture, allowing fine quartz to slip into the coarse fraction or escape with process air—increasing exposure risk and hurting product quality.

- Higher energy consumption: Maintaining high airflow and overcoming pressure drops requires substantial fan power, driving up electricity costs, heat loads, and filter wear.

Modern screening machines tackle the problem differently. With precision meshes and controlled vibration, they typically deliver a cleaner cut at the target size and use significantly less process air, reducing total energy demand and simplifying dust collection.

Direct-excited screening: precision where it counts

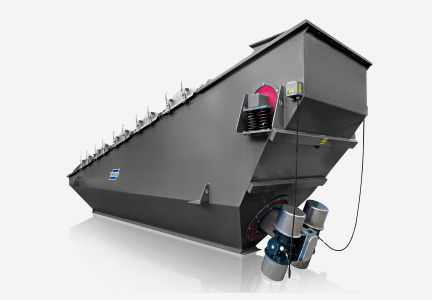

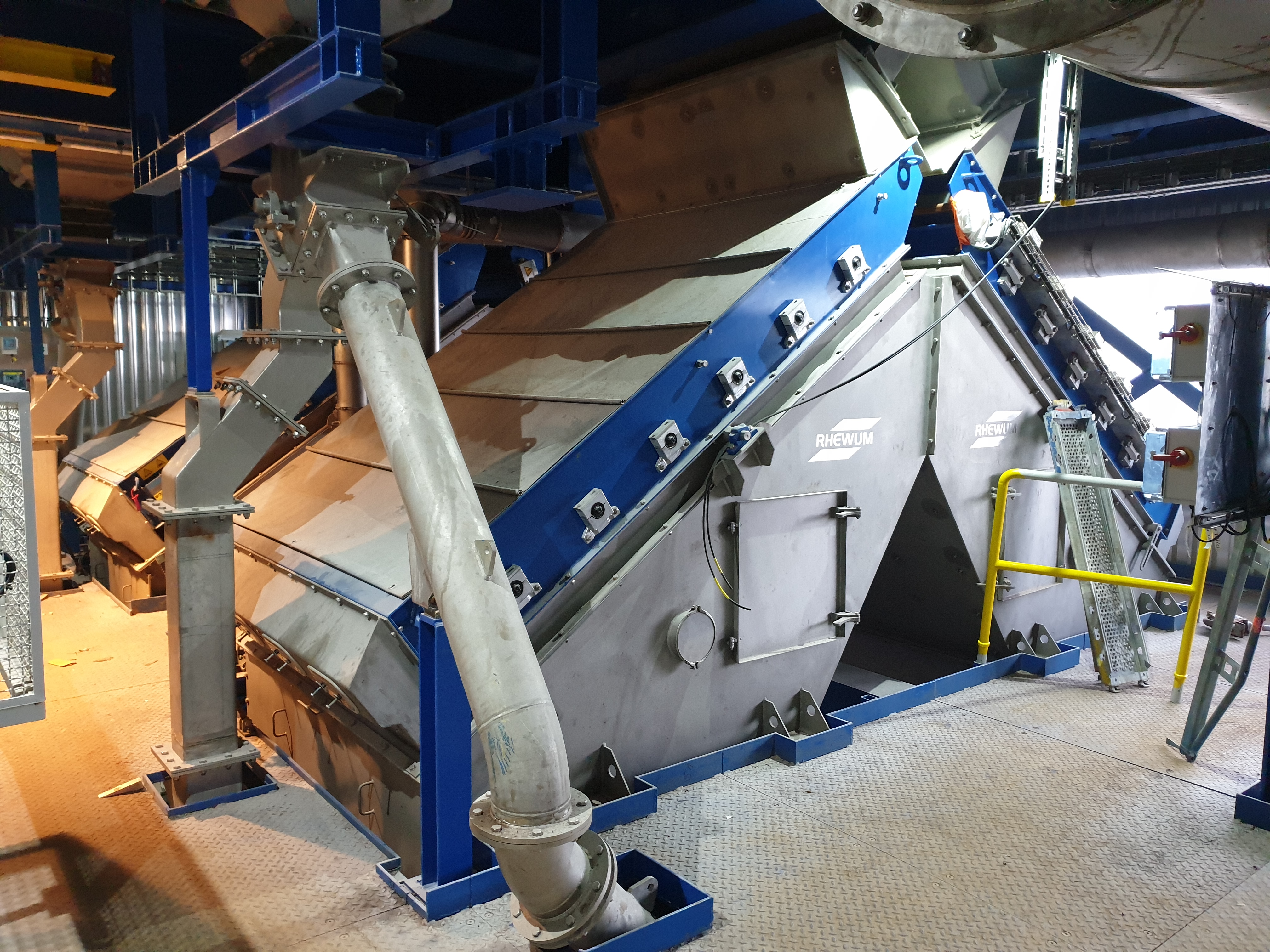

Direct-excited screens—like those from RHEWUM—drive the screen cloth itself at high frequency while keeping the housing static. This targeted excitation creates uniform micro-throws across the mesh, promoting rapi...

+ Read more

Direct-excited screening: precision where it counts

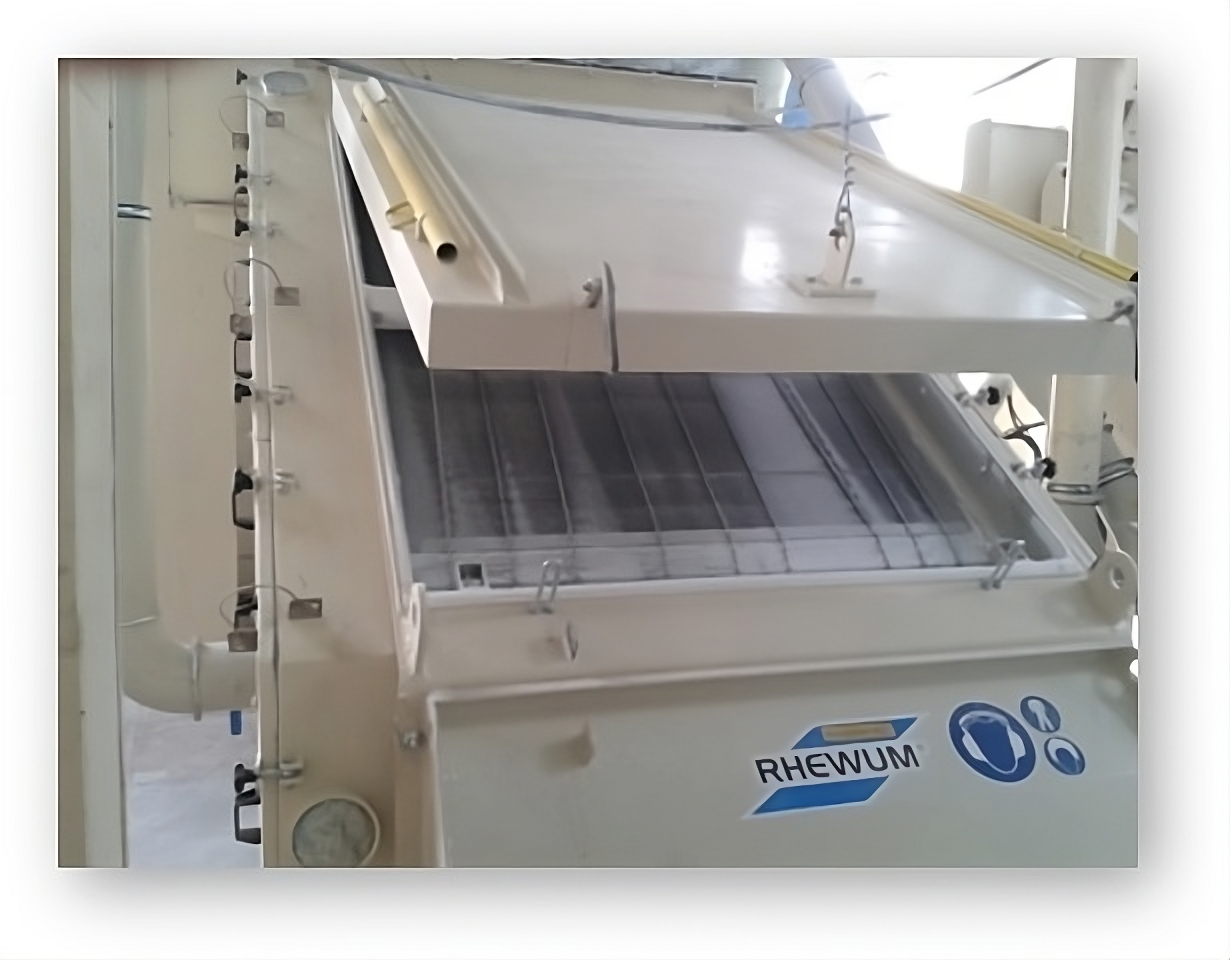

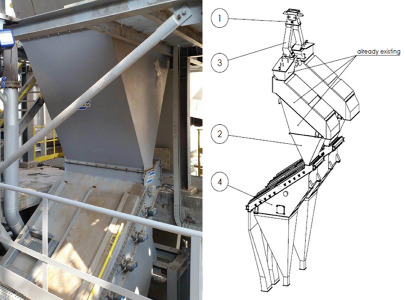

Direct-excited screens—like those from RHEWUM—drive the screen cloth itself at high frequency while keeping the housing static. This targeted excitation creates uniform micro-throws across the mesh, promoting rapid stratification and preventing blinding. The result is a consistently narrow cut curve at the chosen aperture, so fine quartz particles are reliably removed even when feed rate or moisture varies. In silica-critical processes, that added separation sharpness directly supports lower airborne RCS and more consistent product specs.

Energy efficiency and containment benefits

Because only the screen mesh is excited—not the entire machine mass—direct-excited screens typically need less drive power than conventional vibratory screens and far less process air than sifters. The mostly static housing is easy to seal dust-tight, enabling smaller extraction volumes and reducing fan energy, filter pulsing, and wear. In practice, that means lower kWh per ton and more compact air-handling systems without compromising cut quality.

How the principle works

- High-frequency exciters transmit vibration directly into the screen cloth

- Controlled micro-throws stratify material quickly: fines pass the apertures; coarse particles move forward

- The housing stays largely still, minimizing dynamic loads and energy waste; frequency and amplitude are tuned to the material for stable, sharp cuts

Total cost of ownership: looking beyond upfront costs

Yes, high-quality screening machines—especially enclosed, low-noise units with automatic cleaning—can cost more initially. But a total cost of ownership view often favors them when silica is involved:

- Energy and filtration: Lower drive power and reduced extraction volumes cut electricity costs and extend filter life.

- Compliance and risk: Sharper cuts reduce airborne respirable silica, supporting OSHA PEL and other regulatory exposure limits while facilitating smoother audits and certifications.

- Yield and quality: Tighter size cuts mean fewer fines in coarse product, less rework, and steadier throughput.

Conclusion: Turning silica control into a competitive advantage

Controlling quartz dust is both protecting your people and protecting your business. While sifters may look cost-effective at purchase, their broader cut curves and higher energy needs increase exposure risk and long-term operating costs. Direct-excited screening—like RHEWUM's approach—targets the mesh directly for consistently sharp cuts, lower kWh per ton, and easier dust-tight containment. That combination supports regulatory compliance, stabilizes product quality, and reduces your total cost of operation.

For plants handling silica-bearing materials, the path forward is clear: invest in precision where it matters most. With direct-excited screens, you get reliable separation performance even under variable loads and moisture—turning compliance pressure into measurable gains in safety, energy efficiency, and uptime.

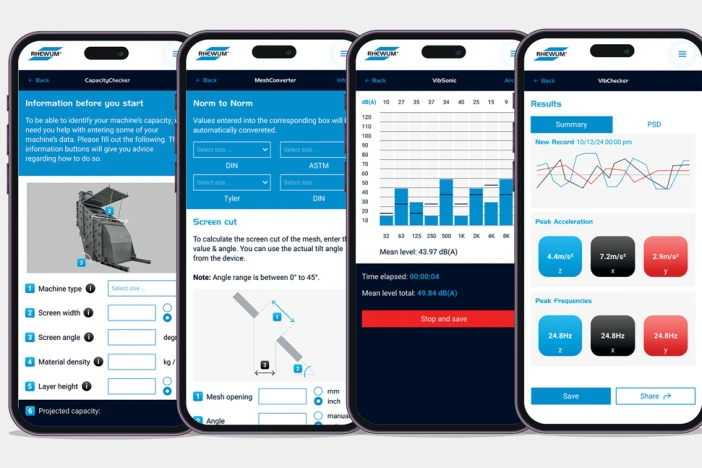

Ready to see the numbers? Request a pilot test with your material or a TCO and energy benchmark for direct-excited screening (RHEWUM) to quantify the cut-sharpness and efficiency gains in your own process.

- Read less

Published by RHEWUM America Inc. on Aug 29, 2025

RHEWUM America Inc.

www.rhewum.us

E: [email protected]

T 888 474 3986 (888 4RHEWUM)

954 990 8847

Address

10424 W State Rd 84

Suite 7

Davie, FL

33324

United States

Show map

Visit our profile