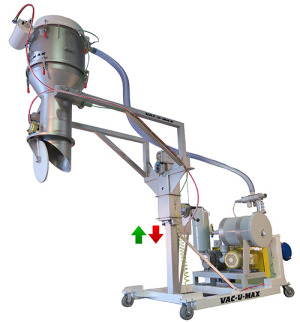

The VAC-U-MAX Pharma-Grade Tablet Press Loading System is a specialized vacuum conveying solution tailored for the pharmaceutical industry, ensuring safe, efficient, and contamination-free transfer of powdered mixtures from drums or cartons directly to tablet press machines.

...

+ Read more

The VAC-U-MAX Pharma-Grade Tablet Press Loading System is a specialized vacuum conveying solution tailored for the pharmaceutical industry, ensuring safe, efficient, and contamination-free transfer of powdered mixtures from drums or cartons directly to tablet press machines.

Key Features:

- High-Precision Conveying:

> Designed specifically for pharma-grade powder handling with a convey rate of up to 1,000 lbs (450 kg) per hour.

> Compatible with a 15ft (4,570mm) hose and wand, allowing flexible setup for various workspaces.

>

Suspended Mounting: Can be suspended above the tablet press with mounting ears.

>

Bottom-Flange Mounting: Sanitary ferrule bottom-flange mount for streamlined integration.

> 12” (305mm) diameter to maintain low “can velocity” for optimal powder separation.

> 60° cone section and 4” (100mm) counterweighted discharge valve ensure smooth, effective discharge.

> Constructed from 316L stainless steel, polished to 180-grit (Ra30) inside and out for pharma-grade cleanliness.

> FDA-approved filter and gasket materials, ensuring safe contact with pharmaceutical ingredients.Unifilter

> Equipped with a non-stick PTFE-laminated Unifilter that’s washable, reusable, and easily removable without tools.

> Automatic pulse cleaning after each batch using compressed air for enhanced filter life and consistent performance.

> Integrated level probe senses tablet press status and automatically starts/stops convey cycles.

> Venturi power unit and NEMA 4X control panel, wall-mountable within 10ft of the press, with provided connecting hose and control tubing harness.

This system offers a robust, easy-to-clean, and highly automated solution for safe, efficient powder transfer in pharmaceutical manufacturing, fully designed and manufactured in the USA. For more information, visit www.vac-u-max.com.

- Read less