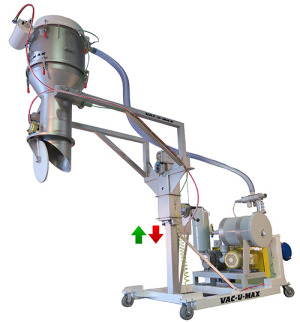

VAC-U-MAX Powder & API Handling System for Capsule Filling Applications

VAC-U-MAX offers a robust dilute-phase vacuum conveying system for efficient and sanitary transfer of powders, additives, fillers, granular materials, and APIs (Active Pharmaceutical Ingredients) directl...

+ Read more

VAC-U-MAX Powder & API Handling System for Capsule Filling Applications

VAC-U-MAX offers a robust dilute-phase vacuum conveying system for efficient and sanitary transfer of powders, additives, fillers, granular materials, and APIs (Active Pharmaceutical Ingredients) directly into capsule filling and other processing or packaging machinery. This system is optimized for continuous operation, designed to meet FDA and 3A sanitary standards, making it ideal for food and pharmaceutical environments.

System Components & Features:

- Sanitary Refill System:

- Comprises a pick-up wand, conveying hose, vacuum receiver with a filter, vacuum producer, and a remote control panel for easy operation and integration with various processing equipment.

- Low Rate Conveyor (LRC):

- Designed to FDA specifications, it pneumatically conveys materials from closed containers, eliminating the need for manual scooping and dumping. This minimizes dust exposure, enhancing safety, particularly with combustible dusts.

- Automated Dust Control & Ergonomic Design:

- Equipped with a gas pulse to clean the receiver’s filter by releasing accumulated dust or materials.

- The ergonomic design ensures easy cleaning, with minimal moving parts for reduced maintenance.

- Flexible Refill Options:

- Can be integrated with various refill sources including drums, bags, bulk bags, intermediate bulk containers (IBCs), and super sacks (FIBCs).

All VAC-U-MAX equipment is manufactured in the USA, ensuring quality and compliance with stringent safety standards.

For additional information or to request a quote, please visit www.vac-u-max.com or call 800-VAC-U-MAX (800-822-8629).

- Read less