VAC-U-MAX Straight-Sided Tube Hopper Material Receivers are designed for efficient, continuous handling of challenging dry bulk solids. Leveraging over 70 years of expertise in pneumatic conveying, these receivers effectively handle difficult-to-transfer materials such as high-fat or high-...

+ Read more

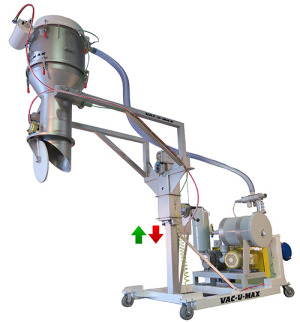

VAC-U-MAX Straight-Sided Tube Hopper Material Receivers are designed for efficient, continuous handling of challenging dry bulk solids. Leveraging over 70 years of expertise in pneumatic conveying, these receivers effectively handle difficult-to-transfer materials such as high-fat or high-moisture content powders, fibrous materials like hemp, lightweight solids, and those prone to bridging or ratholing.

Key Features:

- High-Efficiency Conveying:

- Rapid discharge rates minimize downtime and enable higher transfer speeds, making it ideal for non-free-flowing materials.

- The straight-sided, edge-free design ends in an automatic discharge valve sized to match the tube diameter, ensuring quick, obstruction-free discharge.

- Robust Construction:

- Available in stainless steel or carbon steel with options for standard or sanitary construction, suiting various industry needs.

- Continuous Operation:

- Short discharge cycles maintain virtually continuous conveying, optimizing loading and batch transfer times.

- Operates without external vibration or agitation, powered by positive displacement vacuum pumps, regenerative blowers, or VAC-U-MAX’s air-operated venturi units.

- Closed-System Design:

- Vacuum operation minimizes contamination and waste, as any leaks are inward, unlike positive pressure systems with outward leakage.

- Dust-free transfer enhances cleanliness and reduces housekeeping needs.

- Versatile Material Intake:

- Materials can be drawn from drums, bags, totes, bulk bags, and other containers, eliminating manual scooping, lifting, and dumping.

This system's simple design, with few moving parts, requires minimal maintenance and downtime, offering reliable performance for complex materials.

For more information or to test your material in VAC-U-MAX’s fully equipped lab, request a quote at www.vac-u-max.com.

- Read less