Bulk bag handling systems emphasize Sterling Systems strength in mechanical engineering and design.

This includes the ability to custom engineer and manufacture bulk bag packaging or filling machines, and

bulk bag dischargers or unloaders. Bulk bags are a very common type of packaging f...

+ Read more

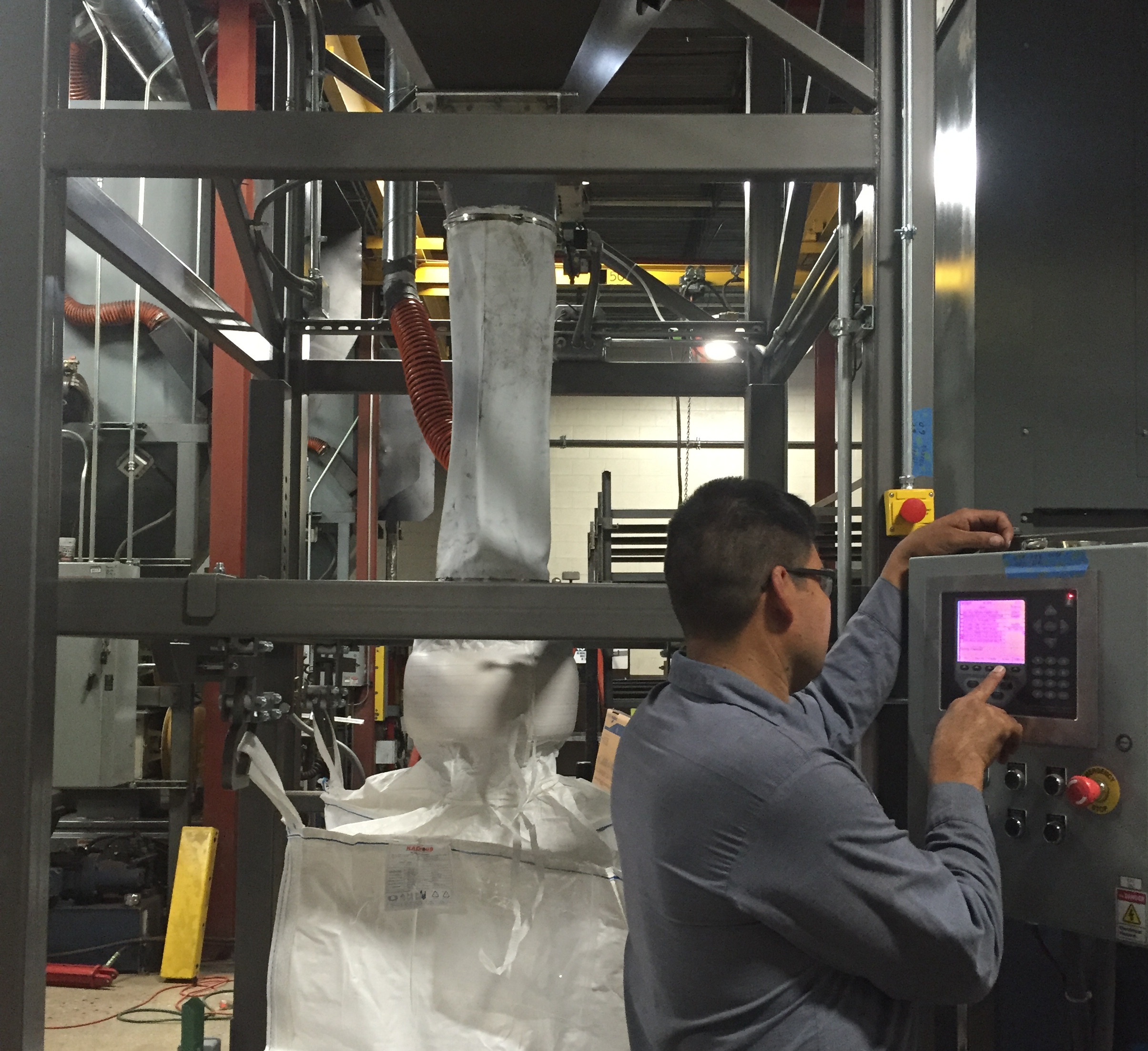

Bulk bag handling systems emphasize Sterling Systems strength in mechanical engineering and design.

This includes the ability to custom engineer and manufacture bulk bag packaging or filling machines, and

bulk bag dischargers or unloaders. Bulk bags are a very common type of packaging for dry bulk materials

in a range of industries. Bulk bags, a.k.a. FIBC‘s (flexible intermediate bulk containers), super-sacks, etc.,

come in a variety of sizes and methods of filling, emptying, and hanging. Bulk bag handling, filling, and

discharging can be incorporated within ingredient batching and weighing systems or be supplied as

standalone process systems.

Bulk Bag Filling Systems: Custom designed to fill and package your dry material into the bulk bags you

utilize, fitting your exact process requirements and meeting your specific objectives.

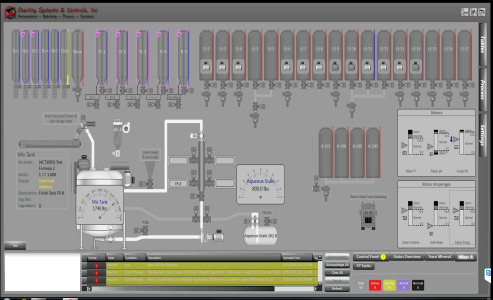

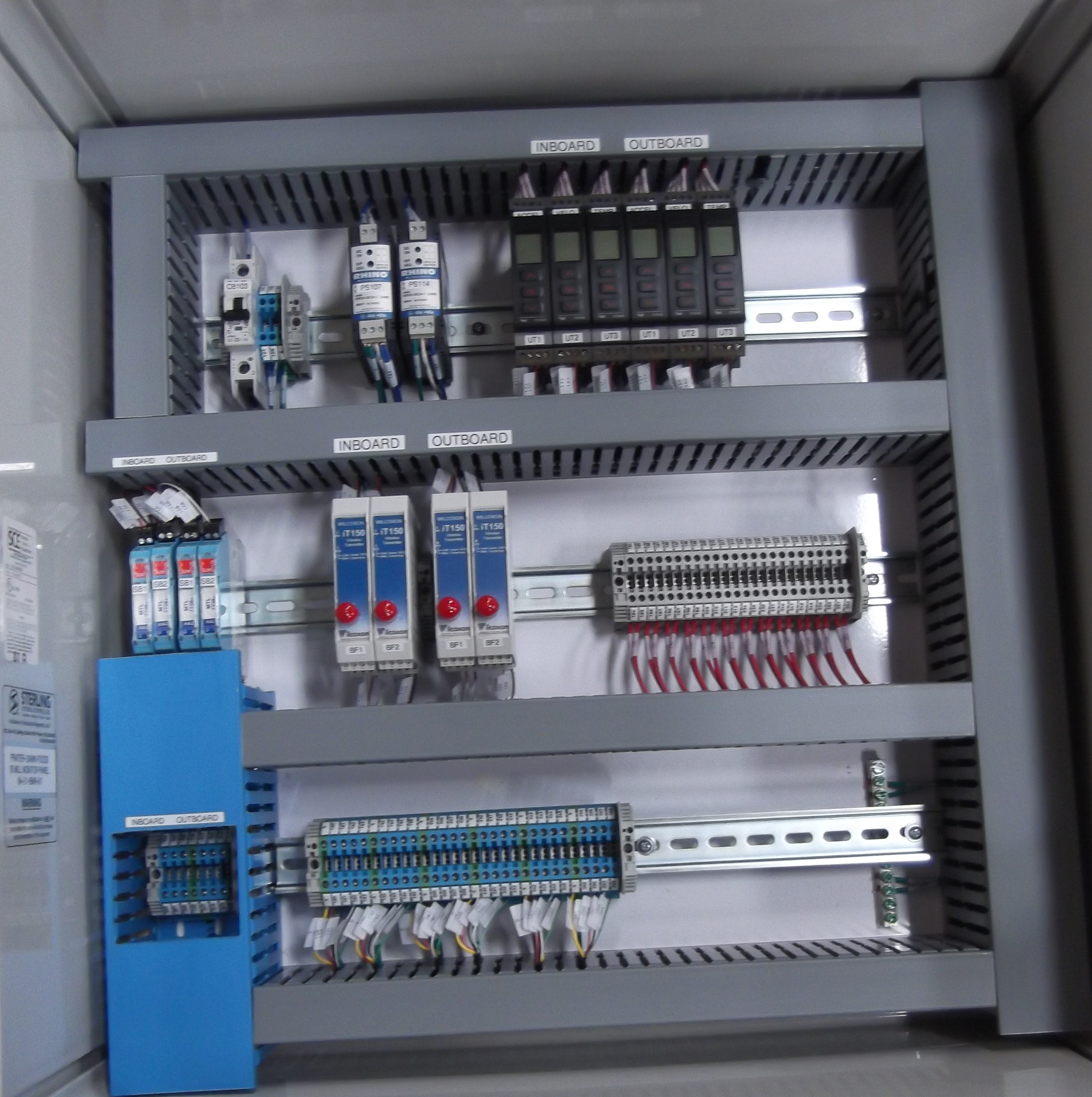

Bulk Bag Unloading Systems: Bulk bag unloading solutions are provided for unloading/discharging your

bulk bags of dry bulk solid materials. Batch weighing can be added along with batching controls. Bulk bag

unloading systems can include mechanical or pneumatic conveying, magnets for tramp metal removal, dust

containment/collection, bag massagers and other features as needed to meet your specific objectives.

BULK BAG FILLING SYSTEMS

BULK BAG UNLOADING SYSTEMS

- Read less

thumbnail-file122499.jpg)

thumbnail-file122504.jpg)