Automation Migration Critical to Long Term Efficiency

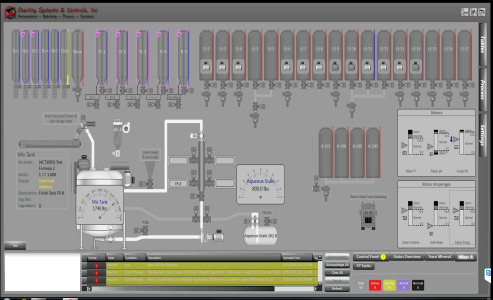

Sterling Systems & Controls, Inc. announces that it provides for continuity of automation upgrade within their batching control automation systems for the baking, food and other industries. Example: A major livestock feed manufacturer has seamlessly maintained state-of-the-art automation control of the feed manufacturing processes across several decades.

Beginning in the early 1970’s Sterling Systems & Controls first provided automated controls for the feed production process. As technology advanced subsequent automation upgrades were affordably and efficiently accomplished in the 1990’s and again in the second decade of the 21st century. This continuity of automation upgrade has greatly assisted the feed manufacturer by increasing process efficiency in providing feed that help livestock producers get the most out of each pound of feed and each head of livestock.

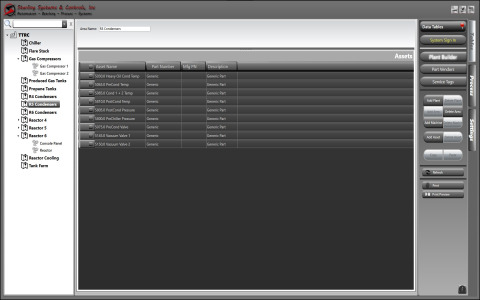

The upgrade program for Sterling Systems’ legacy automation and control software is introduced as FreshStart™ and reasons for upgrading to .NET based instrumentation software include Scalability, Availability of New Apps such as Preventative Maintenance Planning, Numerous ERP Interface Options an...

+ Read more

The upgrade program for Sterling Systems’ legacy automation and control software is introduced as FreshStart™ and reasons for upgrading to .NET based instrumentation software include Scalability, Availability of New Apps such as Preventative Maintenance Planning, Numerous ERP Interface Options and much more.

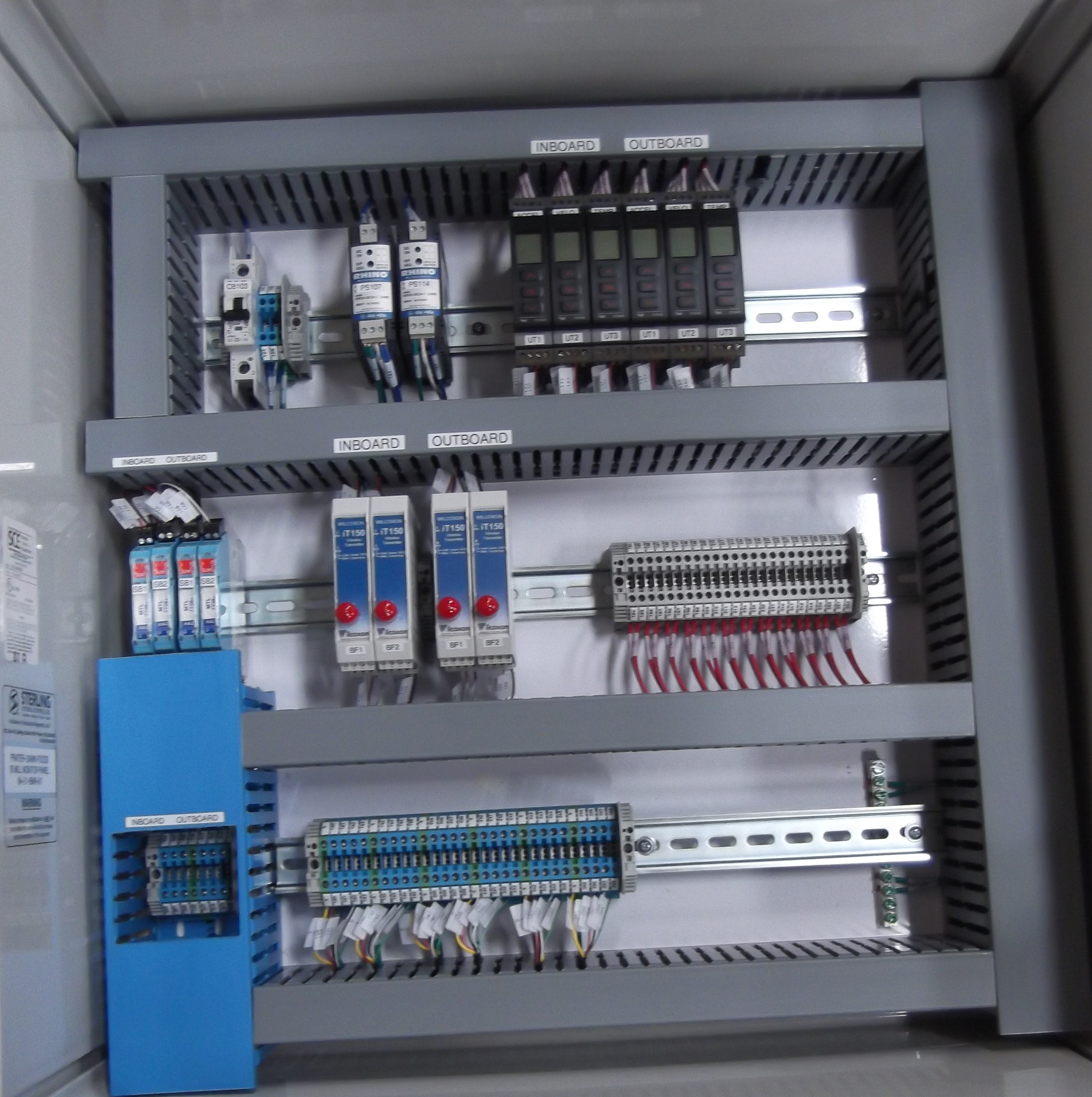

Sterling Systems is a UL listed control panel builder. This, along with Sterling’s deep knowledge of automation technology and understanding of customer applications/processes in a wide range of industries means we are uniquely suited to provide automation and control systems that will be expandable and stand the test of time, easily maintaining state-of-the-art.

- Read less

Published by Sterling Systems and Controls, Inc. on Oct 18, 2021

thumbnail-file122499.jpg)

thumbnail-file122504.jpg)