Troubleshooting Bulk Powder Flow Problems

Powder flow problems cause frustration and hours of expensive downtime. They can also damage machines, create backups, and produce sub-par products. Some types of materials, machines, and working conditions make powder flow problems more likely.

We’ve identified the most common powder flow problems and flow control solutions to help you solve these troublesome inefficiencies.

1. Problem: No Flow

Under normal operating conditions, the material should flow through the system without interruption. If no-flow alerts are a regular occurrence, the system is not optimally designed for either the material or the environment. This may occur in environments with high humidity, materials with high moisture content, solid materials that are irregularly shaped, or materials with certain coatings.

Solution: Agitation

Depending on the cause of the no-flow problem, a few solutions are available. They include:

A mechanical agitator before feeder entry

Vibrator added to hopper

Air pads to aerate product

Each of these are long-term solutions that will ultimately save your time and money by eliminating downtime. When making these upgrades, make sure to conduct proper testing. Consider carefully where and how to mount the devices, and how often they should operate to be most effective.

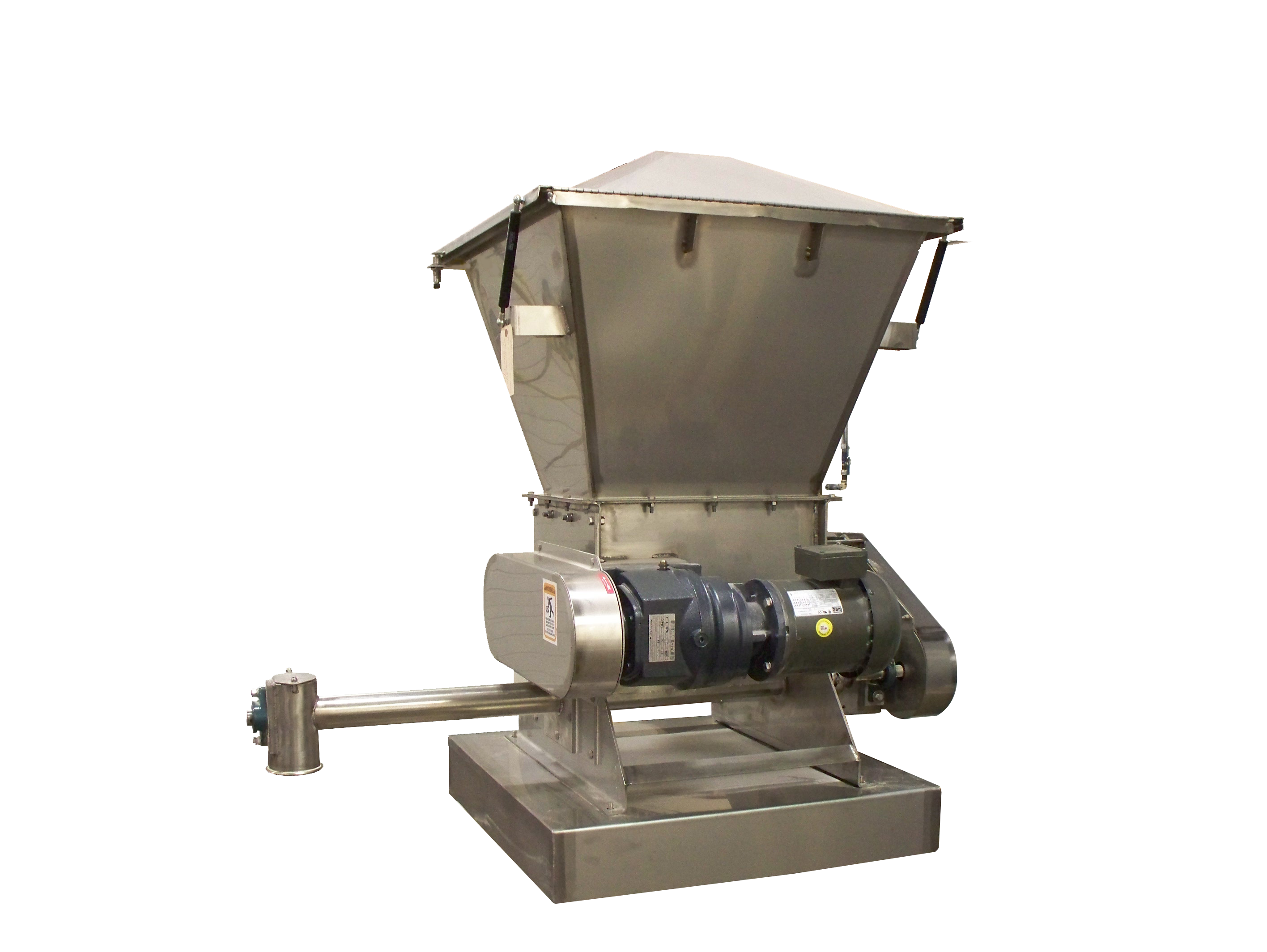

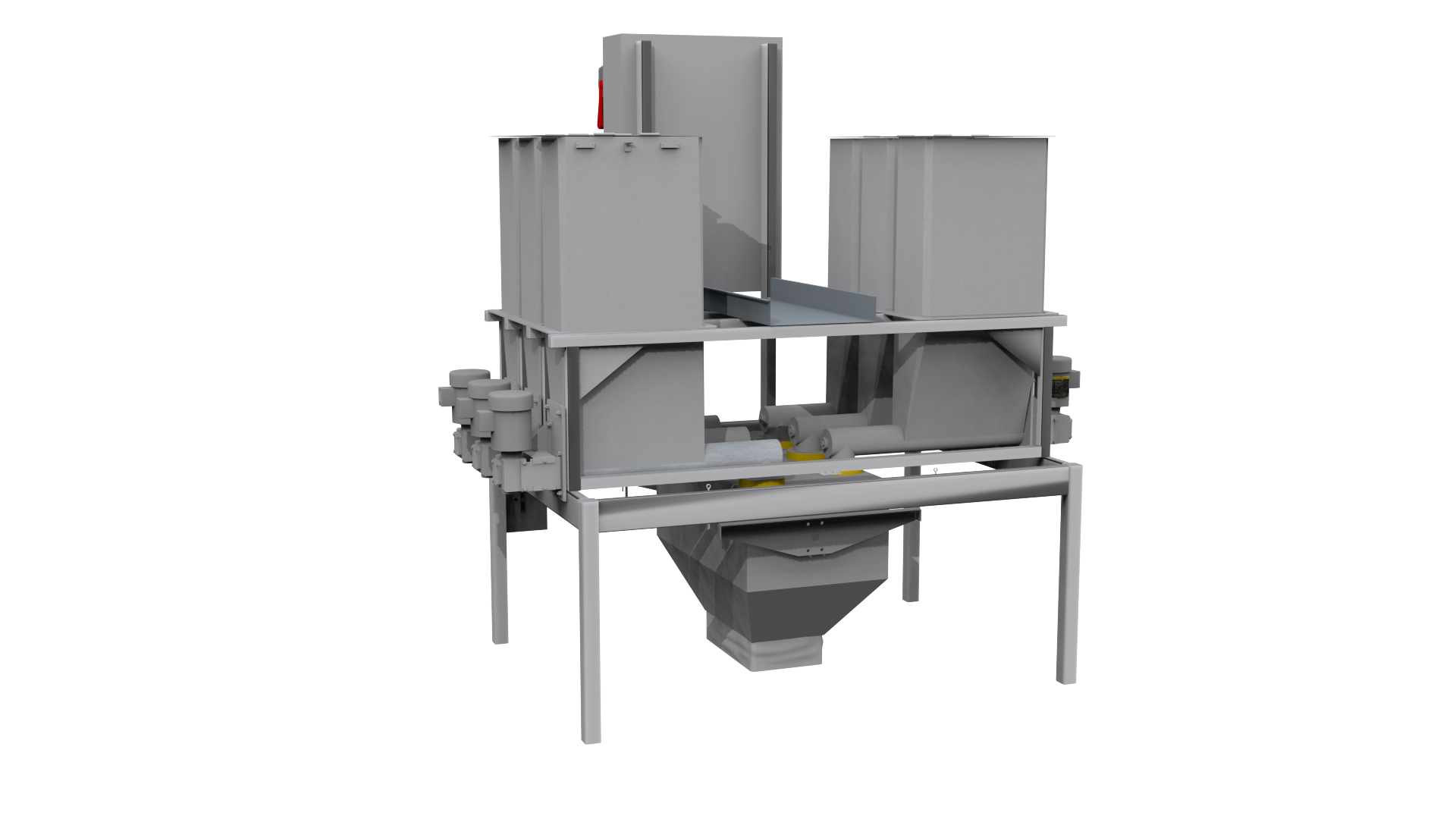

Micro Ingredient Scale

Micro Ingredient Scale

2. Problem: Low Flow

This powder flow problem may go unnoticed for long periods since it doesn’t directly cause downtime. However, insufficient flow can affect all downstream systems. Low flow may be caused by obstructions above the feeder, or misalignments. This may also occur if t...

+ Read more

2. Problem: Low Flow

This powder flow problem may go unnoticed for long periods since it doesn’t directly cause downtime. However, insufficient flow can affect all downstream systems. Low flow may be caused by obstructions above the feeder, or misalignments. This may also occur if the materials are too thick or the feeder is too small.

Solution: Bigger or faster feeder

The ideal flow control solutions for this problem will either expand the feeder to increase volume at slower speeds, or speed up the feeder to push more material through faster.

Upgrade to larger feeder

Add variable frequency drive

Change reducer on drive

- Read less

Published by APEC-Automated Process Equipment Corp. on Oct 13, 2023

APEC-Automated Process Equipment Corp.

www.apecusa.com

E: [email protected]

T 888-374-1001

616-374-1000

Address

1201 N. Fourth Ave.

Lake Odessa, MI

48849

United States

Show map

Visit our profile