Gain-in-Weight vs. Loss-in-Weight Batching Systems: Pros and Cons

Selecting the right batching system for your needs can make a huge difference in you ROI and efficiency. There are different factors to consider in gain-in-weight versus loss-in-weight batching systems, including cost, accuracy, speed and downtime.

Let’s dive into their differences, as well as the pros and cons of each batching system.

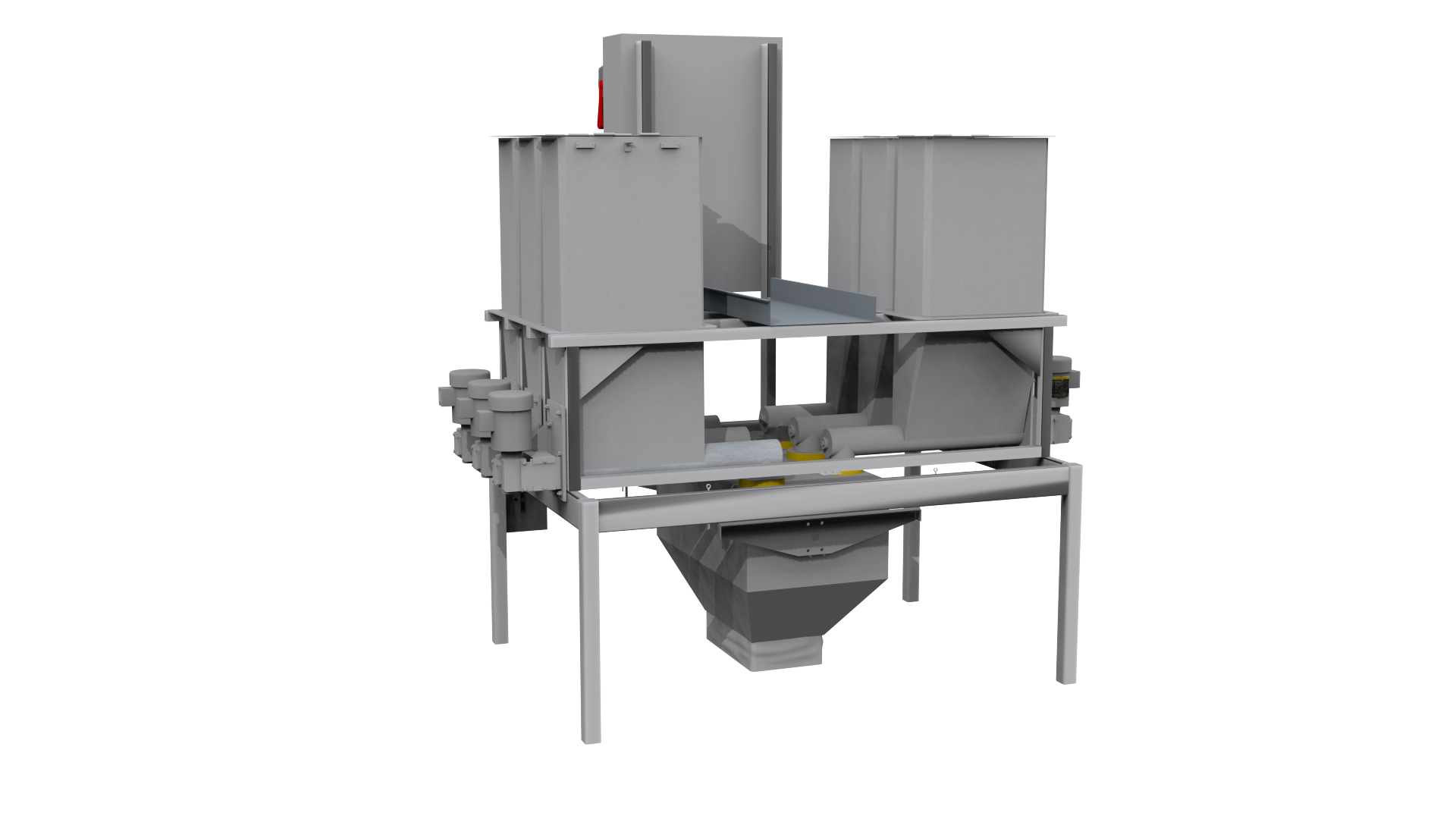

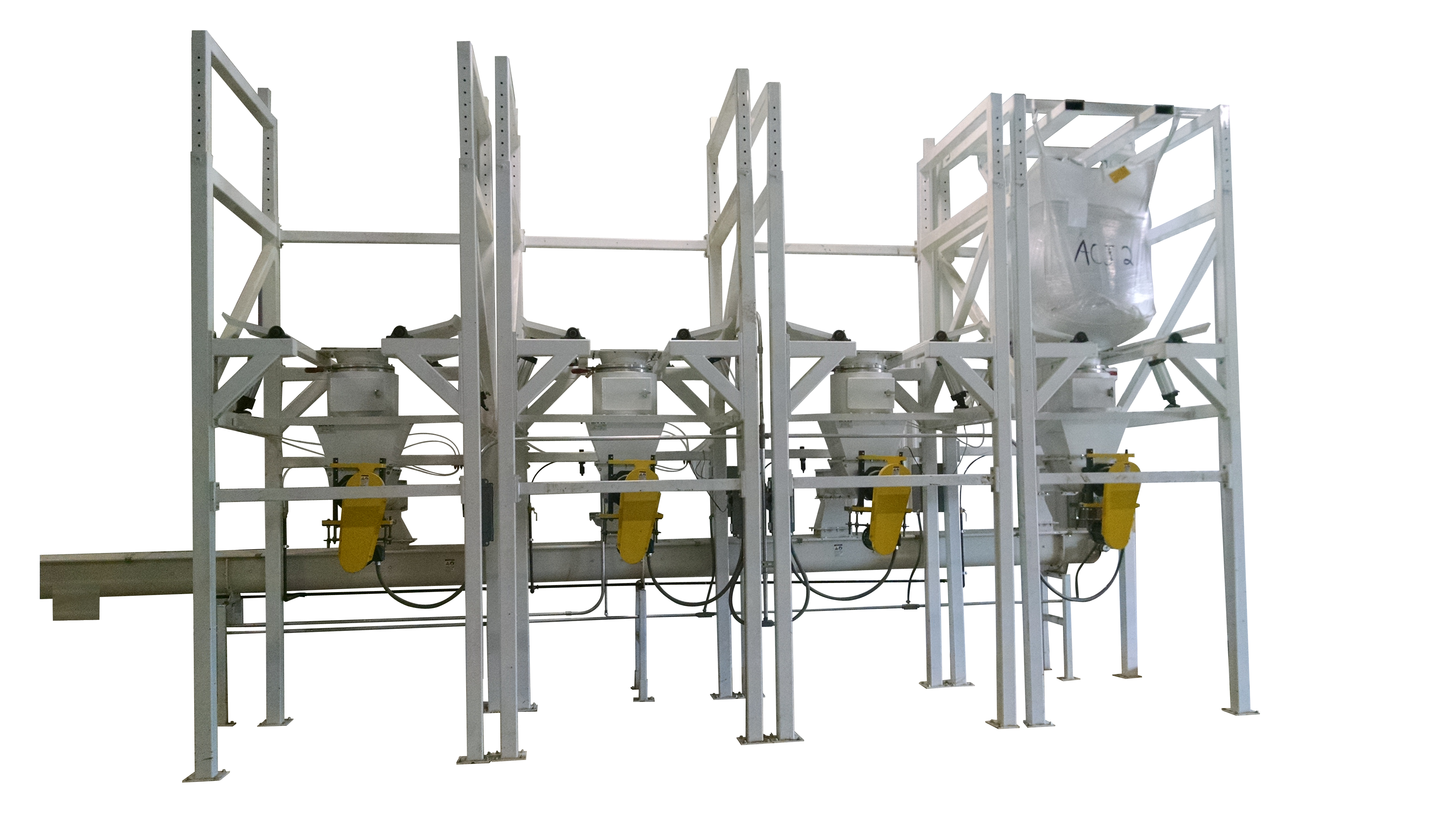

What is Gain-in-Weight or GIW Batching System?

A gain-in-weight batching system utilizes multiple feeders to dispense into a single scaling vessel or container. The vessel or container can either sit on the scale or can be integrated into the scale with the load cells attached.

The vessel or container is sized and designed based on a total maximum batch capacity for the ingredients assigned to the scale.

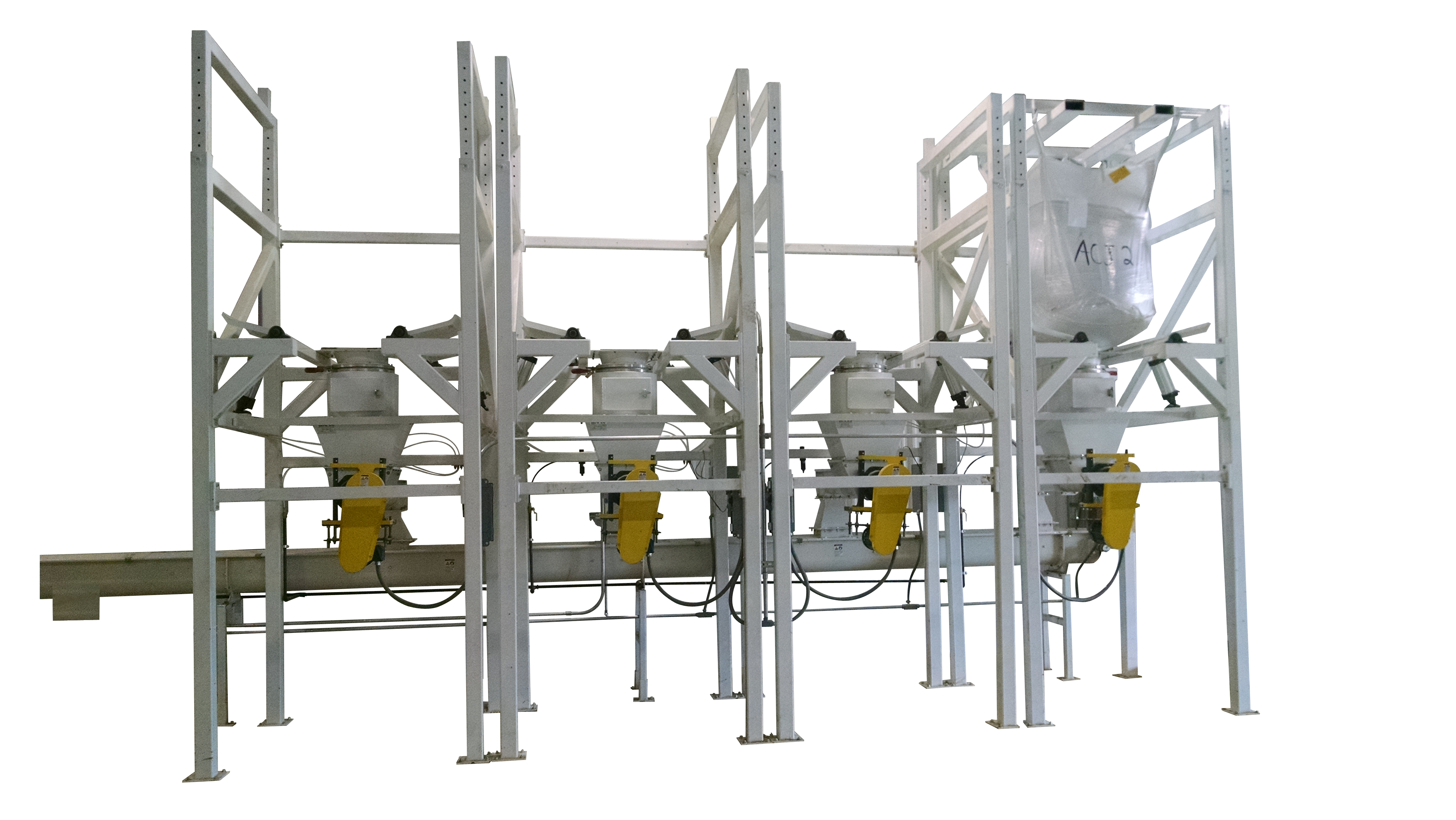

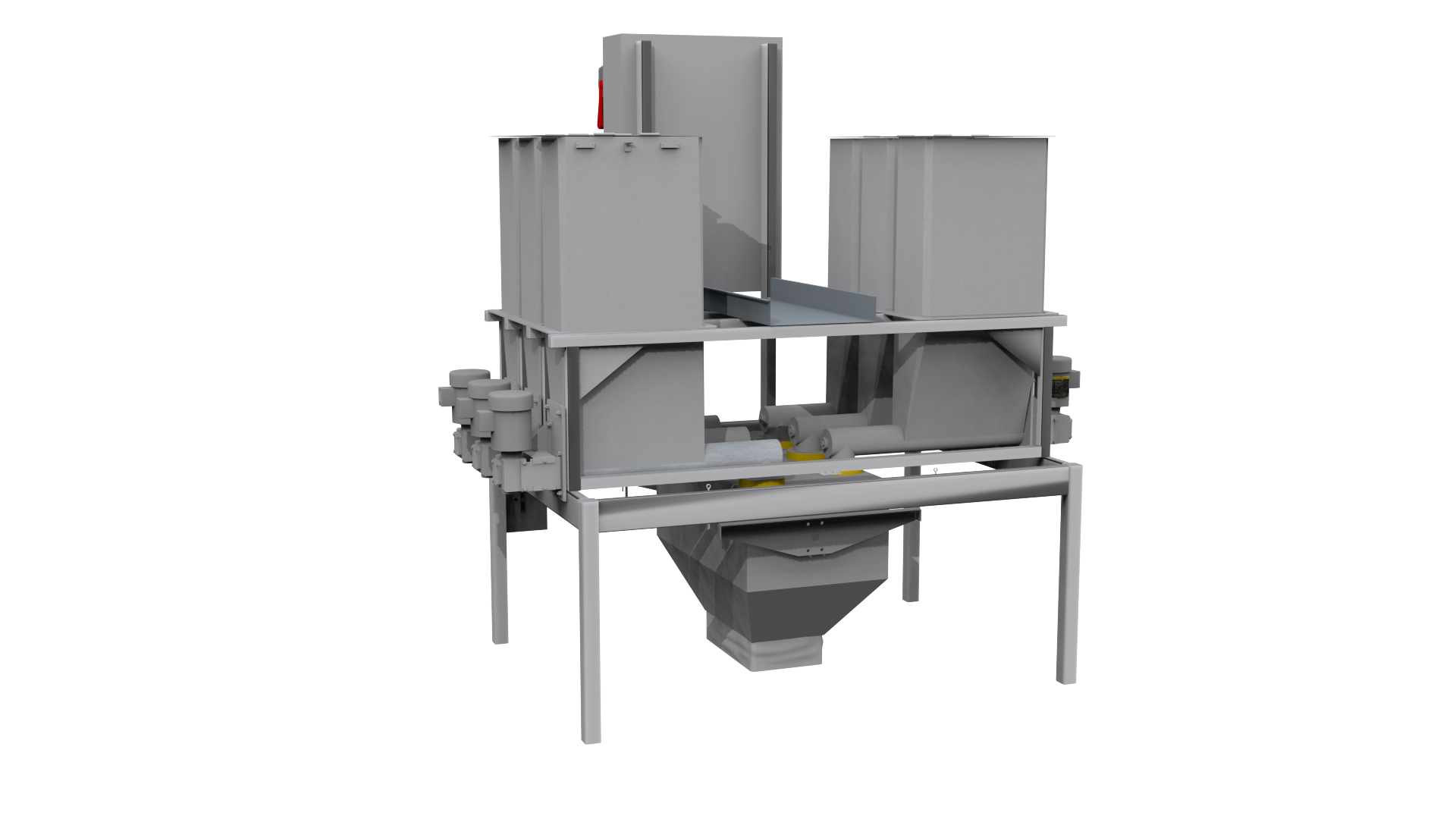

What is Loss-in-Weight or LIW Batching System?

A loss-in-weight batching system utilizes a scale as a part of the ingredient storage hopper. As the ingredient is dispensed into an independent vessel or container, the weight loss is totalized until the desired amount has accumulated.

The storage hopper is sized and designed based on total maximum ingredient capacity required.

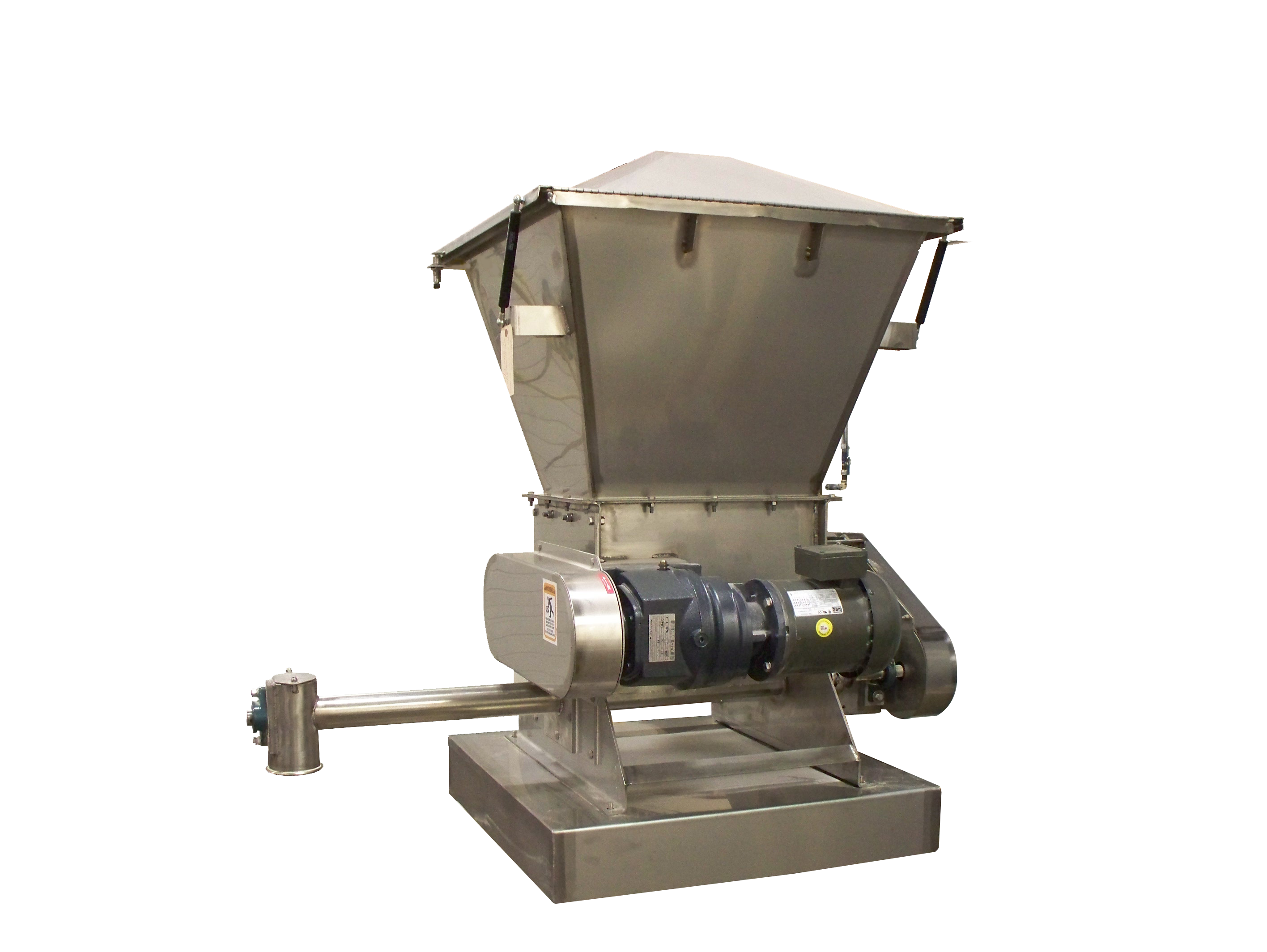

Micro Ingredient Scale

Micro Ingredient Scale

Pros & Cons of GIW vs. LIWThe pros and cons can be categorized into four major categories:

CostAccuracySpeedDowntime

Analyzing each category will assist in determining which system is best for your process. Balancing these categories is ke...

+ Read more

Pros & Cons of GIW vs. LIWThe pros and cons can be categorized into four major categories:

Cost

Accuracy

Speed

Downtime

Analyzing each category will assist in determining which system is best for your process. Balancing these categories is key to making the right choice. So, what are the pros and cons of each?

GIW Pros & Cons

Pro: Low cost

Because only one feeder runs at a time, electrical hardware used for controls can be shared between ingredient bins.

Common components reduce the need for a large inventory of replacement parts. You should always request that the manufacturer use components readily available in your area.

Pro: Accuracy and storage balance

Scales can be designed to higher accuracy standards due to reduced capacity requirements based on the formula’s ingredient usage for a single batch.

This reduces the need for constantly refilling storage bins by increasing capacity to a size that fits the process.

Con: Downtime on hardware failure

Major electrical components – such as VFDs and scale indicators – used in operating the GIW system are shared. Failure of one will influence all the feeding devices.

Con: Speed

Cycle time is determined by the number of feeders assigned to the gain-in-weight scale. The more ingredients assigned to a scale within the formula, the more run time will be required to complete the batch.

- Read less

Published by APEC-Automated Process Equipment Corp. on Oct 13, 2023

APEC-Automated Process Equipment Corp.

www.apecusa.com

E: [email protected]

T 888-374-1001

616-374-1000

Address

1201 N. Fourth Ave.

Lake Odessa, MI

48849

United States

Show map

Visit our profile