7 Types of Industrial Mixers

At first glance, mixing ingredients together doesn’t seem too complicated. But, when you want to mix ingredients together that simply don’t want to mix, or if you want to mix hundreds of tons of materials together to ramp up production, mixing quickly becomes more complicated.

Industrial mixers have revolutionized many different industries as they play an important role in large-scale production of all types.

A mixer could include any device that’s designed to mix raw materials or ingredients together. For the purposes of this blog post, an industrial mixer refers to a piece of equipment that is designed to mix materials or ingredients together as a part of a larger production process. This might include mixers involved in food processing, chemical processing, pharmaceutical products, plastic processing, and much more.

Categorizing different industrial mixers and agitators can also be more complicated than it may seem. Some mixers that are similar in appearance may use very different forces or designs to mix materials. Or, some commercial mixers use similar forces to mix materials, but look and operate very differently.

In this post, we categorized mixers mostly based on their design. Some other ways of categorizing mixers may include:

Industry: Mixers are used in a wide variety of industries, and each could be categorized this way. Matter: Some mixers are designed to mix gasses, liquids, solids, or any combination thereof. Force: Different mixers use different types of force to blend materials together, like gravity, rotation, pressure, shear, and more. Function: some mixers are meant to mix two substances that don’t normally combine, others to create a completely homogeneous mixture, others to mix materials within a certain coefficient of variation. Keep in mind, this is not an exhaustive list. For this blog post, we’ll look at some of the most common types of industrial mixers and blenders, how they work, and some of the industries and products they may be used for.

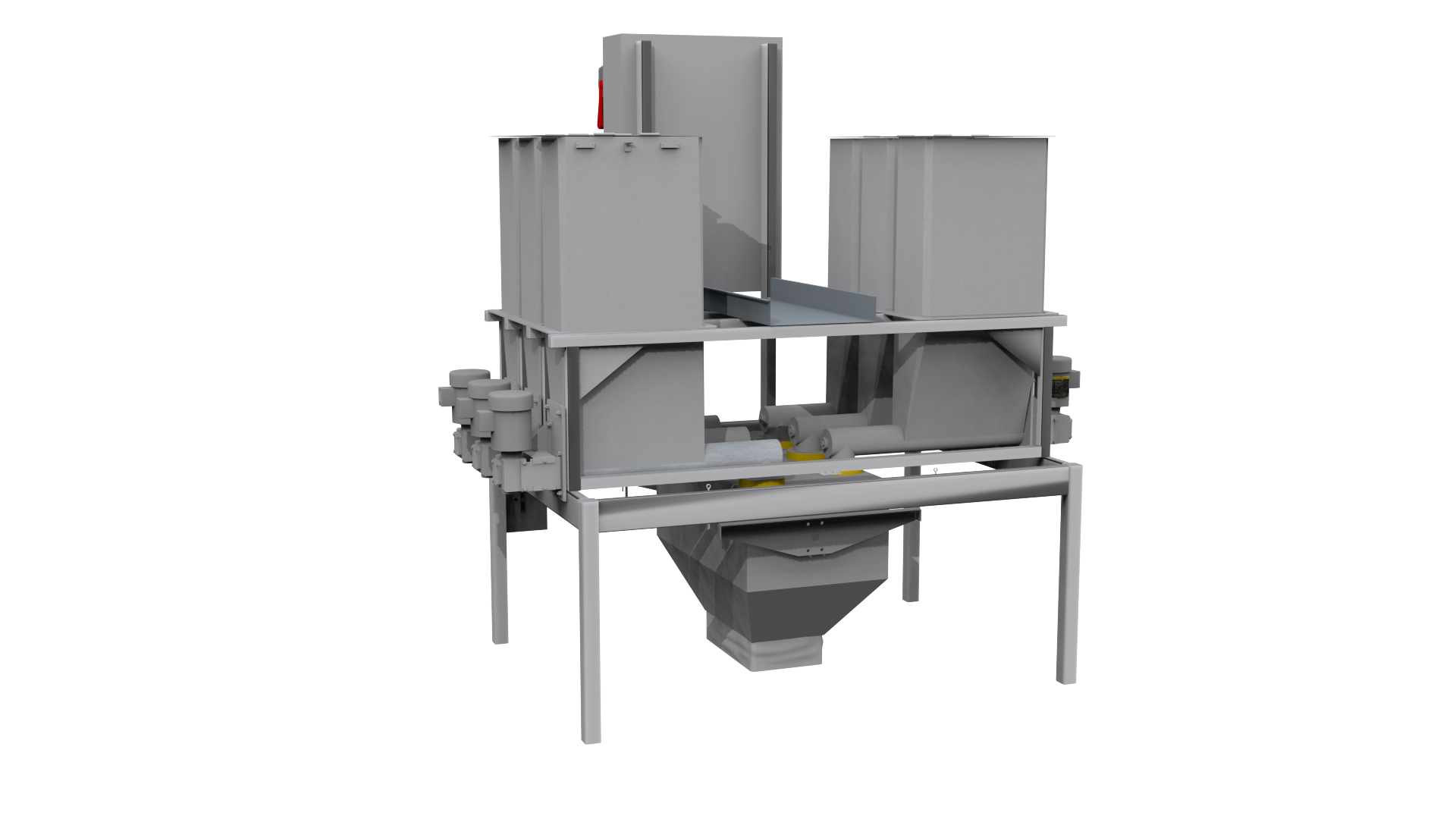

Horizontal Ribbon Mixer

Horizontal Ribbon Mixer

1. Horizontal Ribbon MixerA ribbon mixer—or ribbon blender mixer—uses two intertwined metal strips, similar in shape to a double helix, to move material from one side of the mixer to the other. As the material passes in each direction, it mixes together. Horizontal ribbon mixers are used in ...

+ Read more

1. Horizontal Ribbon Mixer

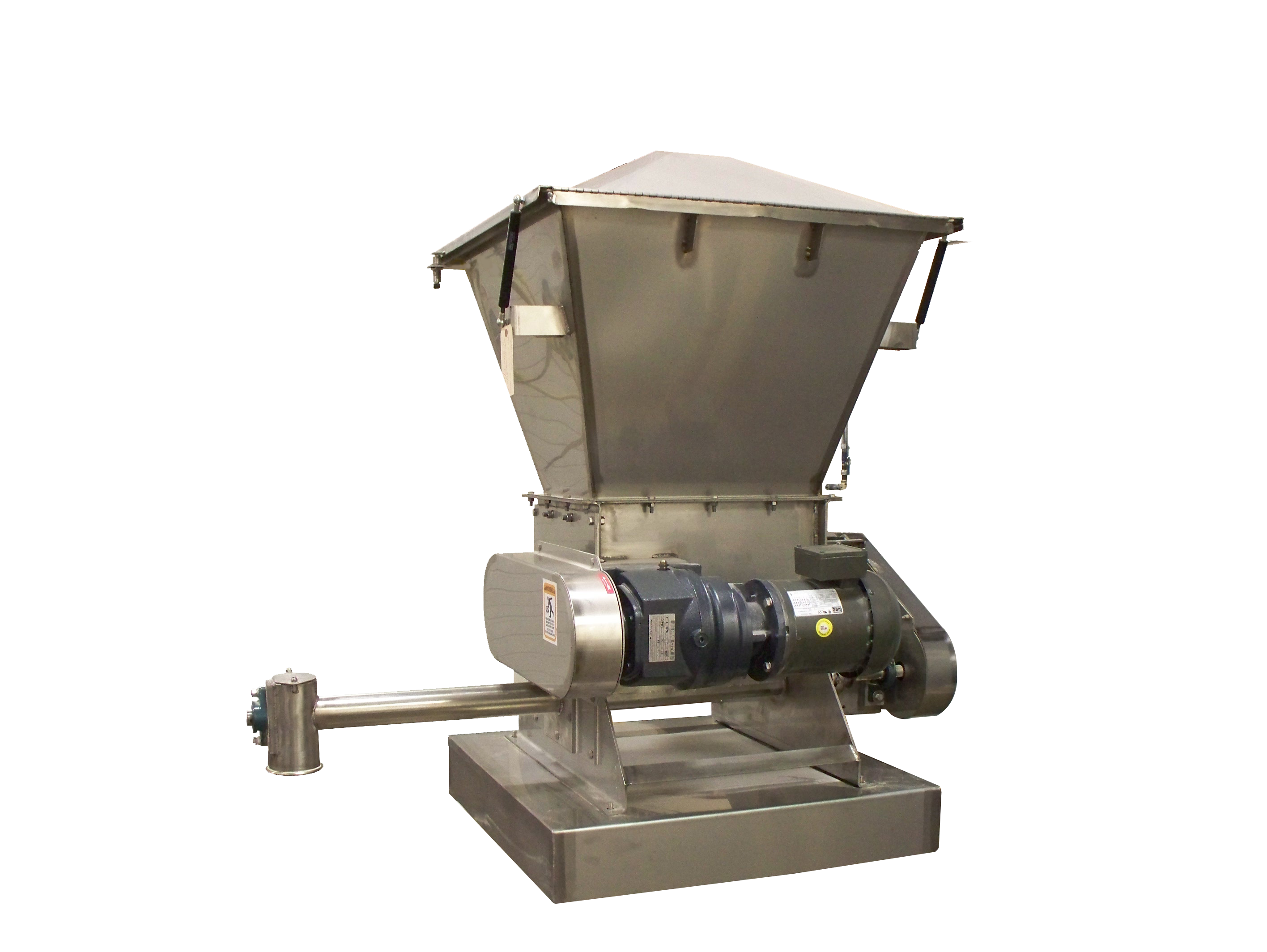

A ribbon mixer—or ribbon blender mixer—uses two intertwined metal strips, similar in shape to a double helix, to move material from one side of the mixer to the other. As the material passes in each direction, it mixes together. Horizontal ribbon mixers are used in a variety of industries, including food processing and chemical processing, and are often used in mixing powders and other solids.

2. Paddle Mixer

A paddle mixer is similar to a horizontal ribbon mixer, except the mixing action is gentler. As the paddles move the material through the mixer, it creates a cohesive mix. This type of industrial or commercial mixer is often used with thick or viscous semi-solids, like salad dressing or salsa.

- Read less

Published by APEC-Automated Process Equipment Corp. on Oct 13, 2023

APEC-Automated Process Equipment Corp.

www.apecusa.com

E: [email protected]

T 888-374-1001

616-374-1000

Address

1201 N. Fourth Ave.

Lake Odessa, MI

48849

United States

Show map

Visit our profile