QA Series Gravity Flow Sifters

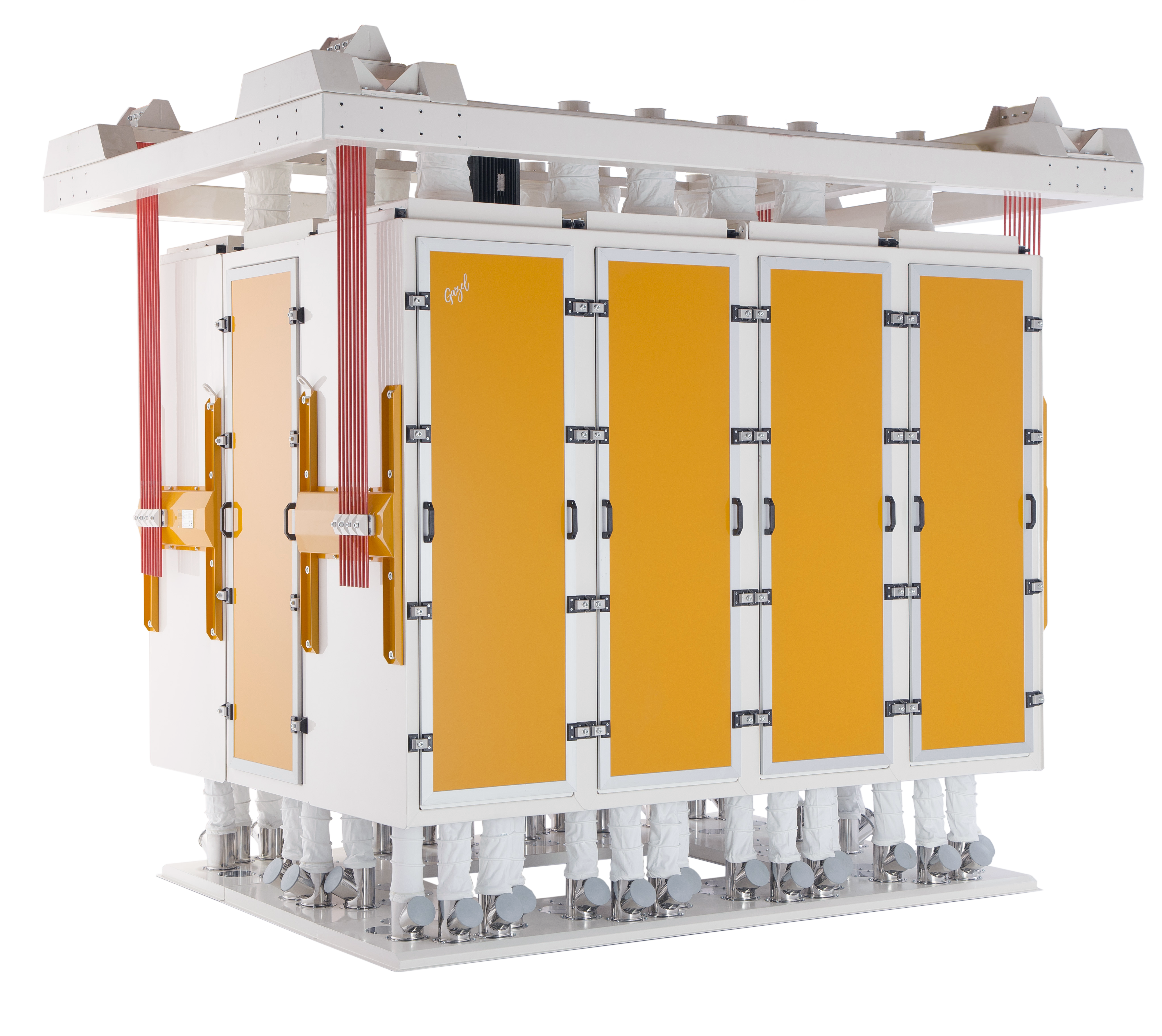

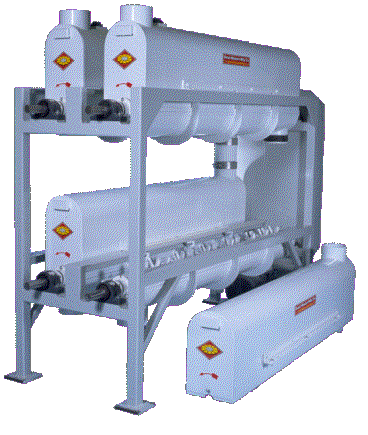

The Great Western QA Series Gravity Flow Sifter utilizes the Tru-Balance drive to allow for accurate separation and sizing of a single product stream into two or more particle sizes.

An important benefit of the reliable Tru-Balance drive is that no massive foundation is required....

+ Read more

The Great Western QA Series Gravity Flow Sifter utilizes the Tru-Balance drive to allow for accurate separation and sizing of a single product stream into two or more particle sizes.

An important benefit of the reliable Tru-Balance drive is that no massive foundation is required. Usually constructed for floor mounting with a top inlet and top discharge, custom configurations for downward directed discharges and multiple floor layouts are easily accommodated.

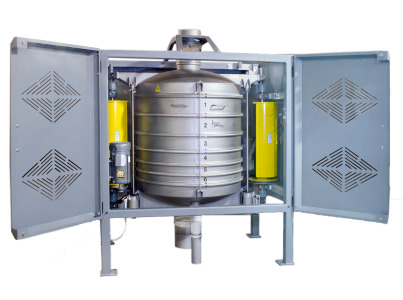

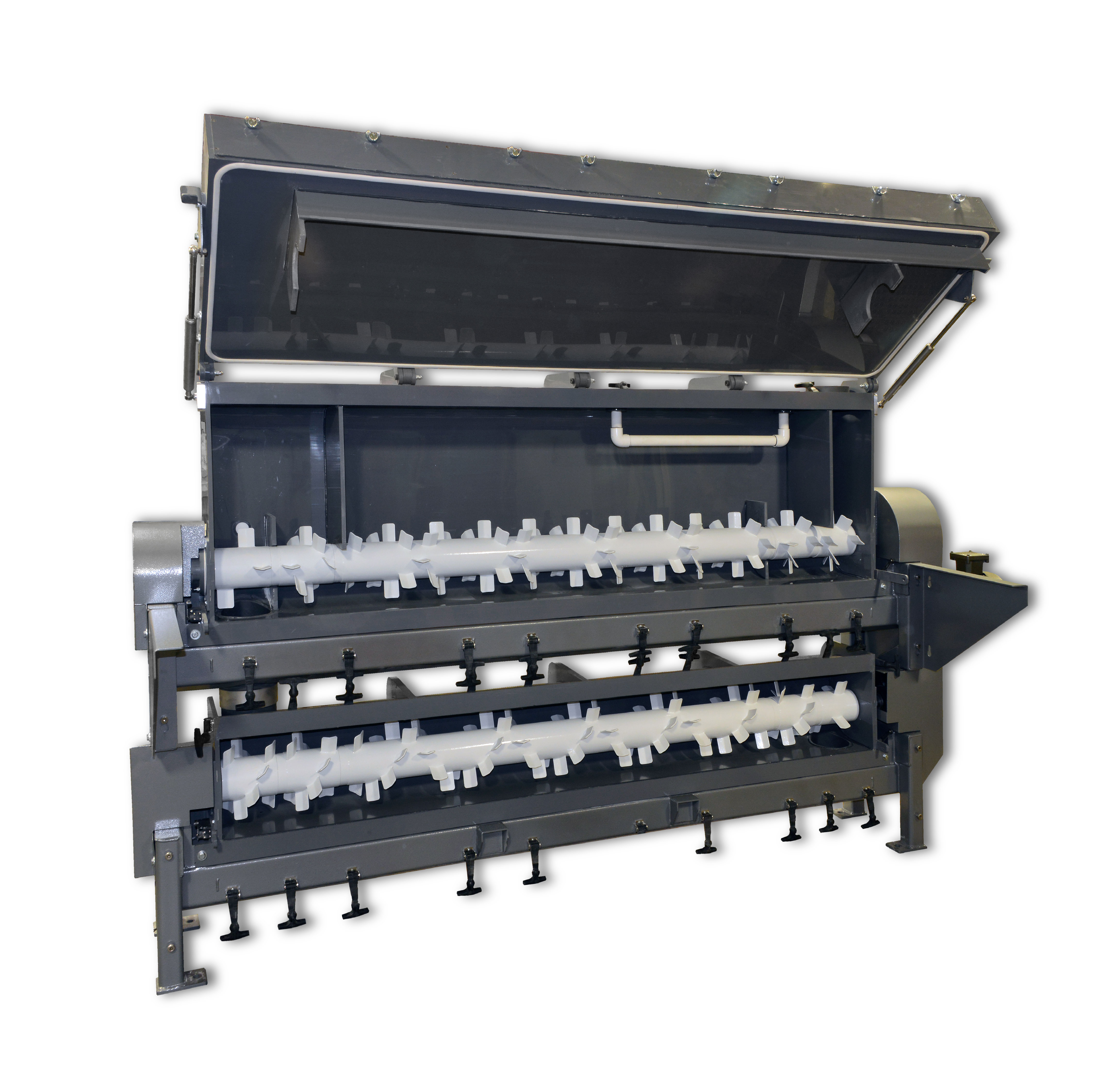

Its compact, space saving design with light weight components enable the sifter to be easily dismantled for inspection, maintenance or cleaning. The sieve rings and screen trays nest-together and are stacked one on top of the other on the lower dome. The number of sieves required is based on the product, conveying rate and sieve mesh size for each application.

A pneumatic sieve compression system and draw rods compress the stack of sieves between the upper and lower domes and create an air-tight unit. The upper and lower domes are connected to the drive components which are supported on the two sides within a tubular frame.

The Gravity Flow Tru-Balance Sifter uses standard motors and V-belts to turn the two counterweights positioned on the left and right sides of the machine. These weights straddle the machine’s center of gravity and counterbalance the mass of the rotating sifter housing. This unique drive mechanism invented by Great Western ensures a smooth, balanced operation and minimizes building structural demands. The shake stays in the sifter! Mechanically, there are no gear boxes that can leak, and no sifter knuckles to wear out. Using pneumatics, the upper drive frame is raised to open the sifter or lowered to compress and seal the sieve stack.

The new Quality Assurance (QA) Series of Gravity Flow sifters, the QA36 and QA46, replace the previous Stainless Steel Sifter models 711 and 821

- Read less