Engineered-to-Application Bulk Material Processing and Packaging Project Increases Process Yield and Improves Downstream Production Throughput Efficiency

This bulk material processing and packaging project was designed, engineered, installed, and commissioned by National Bulk Equipment [NBE] for a fullstream application requiring the discharge, screening, decontamination, and bulk packaging of multiple specialty-engineered, extreme-performance materials.

(HOLLAND, MICHIGAN) -- This bulk material processing and packaging project was designed, engineered, installed, and commissioned by National Bulk Equipment [NBE] for a fullstream application requiring the discharge, screening, decontamination, and bulk packaging of multiple specialty-engineered, extreme-performance materials. Raw materials are received in bulk bags and bulk bins of differing sizes and weights. Specific formulations of the end-product and particular material infeed interfaces of downstream production equipment require the project to simultaneously fill bulk bags, bulk storage totes, and drums. These functional requirements, together with the customer’s need for quantifiable performance metrics, application-specific guidance, and collaborative project management made engineer-to-application (ETA) project delivery a necessity.

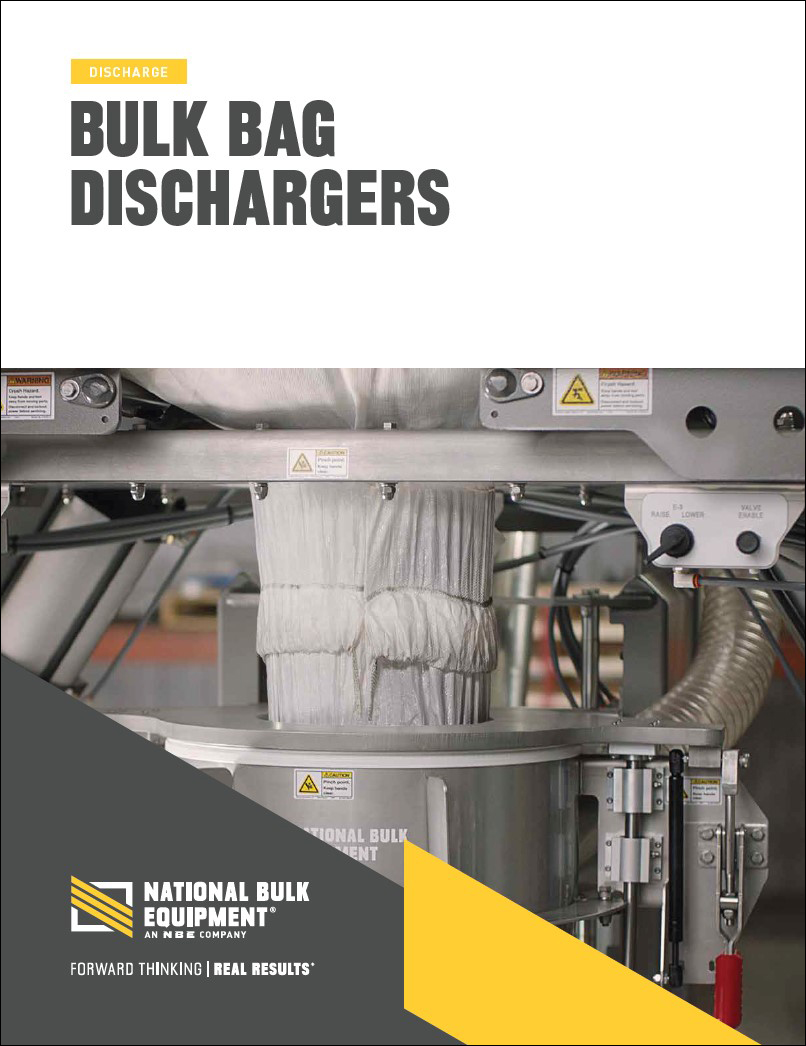

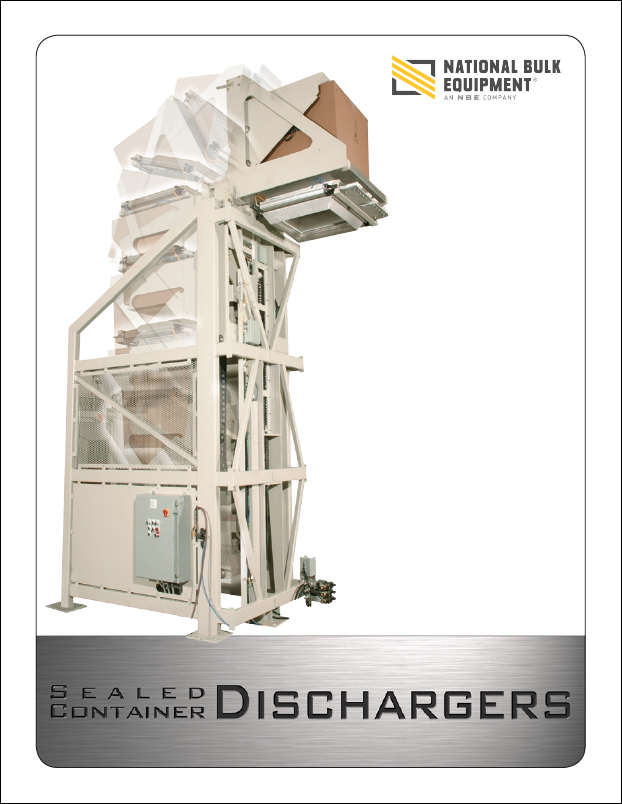

Upstream bulk material unloading begins with two, NBE forklift-loaded, bulk container discharging stations. Each station has a load capacity of 3,000 pounds and can receive bulk bags and bulk bins. When preparing a bulk bag for discharge, the spout interface of the NBE discharge station enables the operator to easily access the bag spout, connect the spout to the system, and enclose the bag spout prior to beginning material flow. When preparing a bulk bin for discharge, a flex connection spout from the bin bottom functions in the same manner as the bag spout. With the bag spout or bin spout connected, the operator initiates material discharge.

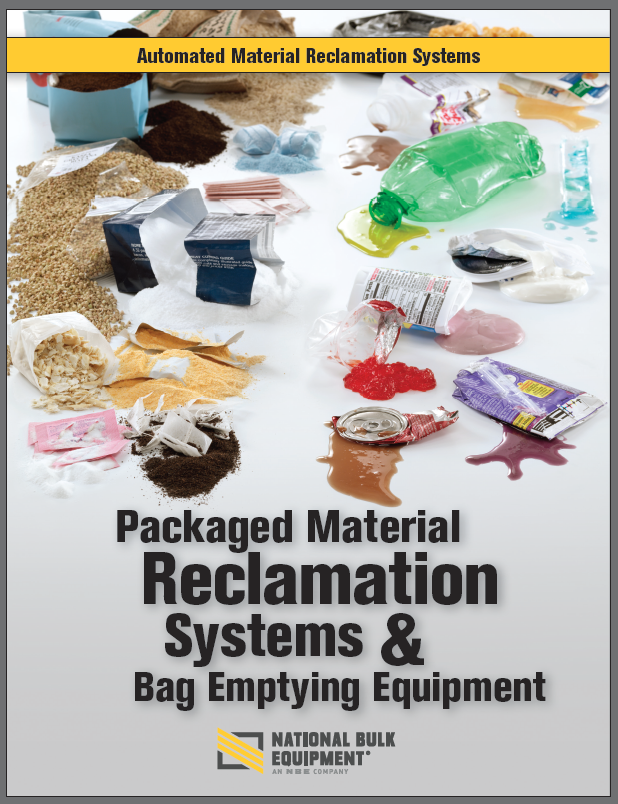

Midstream bulk material processing operations of this NBE project prepare the bulk materials to ensure characteristics of the finished, bulk-packaged product meet the demanding size and purity specifications for downstream production. Preparations necessary for the received raw material will determine which of the two NBE bulk material processing and packaging systems will handle the input. These midstream preparation functions include sizing the materials to micron-level specifications, separating the materials according to size, and magnetic decontaminating of the sized and separated materials.

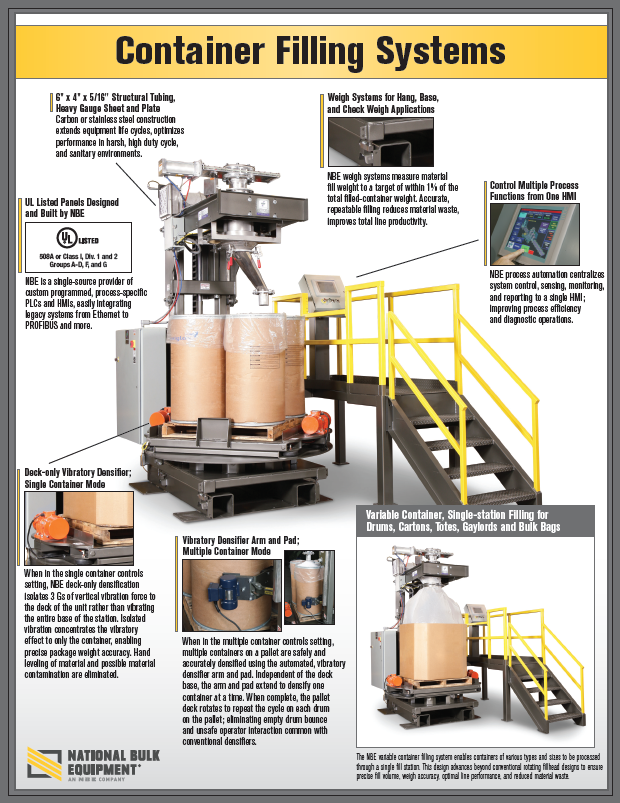

Downstream bulk material packaging operations utilize NBE engineered-to-application bulk container filling systems. Each of these filling systems is designed to easily changeover for filling bulk bags, bulk totes, or drums. Depending on processing requirements, filled-container weights range from 600 to 4,000 pounds. The fillhead on each NBE bulk container filling system is designed to provide a dust-tight interface to the container being filled, whether the interconnect is a bulk bag spout, a tote cover flange, or a drum cover. Material dusting that may occur within the fillhead is routed away within the system and recovered at a central collection unit. This NBE engineered-to-application fullstream project enabled this bulk processing and packaging enterprise to move beyond the constraints of build-to-order and engineer-to-order machines and leverage NBE engineered-to-application project delivery to increase process yield and improve downstream throughput efficiency.

.jpg)

About NBE Holdings Company

NBE Holdings Company, based in Holland, Michigan, is a privately held corporation. The NBE Holdings Company portfolio of companies includes National Bulk Equipment, Inc. and Brawn Mixer. Employing over 200 staff members, the companies o...

+ Read more

About NBE Holdings Company

NBE Holdings Company, based in Holland, Michigan, is a privately held corporation. The NBE Holdings Company portfolio of companies includes National Bulk Equipment, Inc. and Brawn Mixer. Employing over 200 staff members, the companies of NBE Holdings Company design, engineer, manufacture, automate, and integrate bulk material handling systems for dry and liquid processing operations, and fluid mixing systems for liquid processing operations. The processing projects and systems of National Bulk Equipment and Brawn Mixer bring optimal process performance to end customers, engineering firms, integrators, and OEMs in industries including food, beverage, pharmaceutical, chemical, and ingredients processing.

Contact: Tim Wiersma, Director of Marketing

Phone: 616-399-2220

- Read less

Published by National Bulk Equipment, Inc. on Jan 19, 2022

.jpg)

.jpg)