Bulk Bag Filling System is Engineered to Application to Improve Operator Interaction, Reduce Material Waste, and Increase Package Throughput

This bulk material packaging system was engineered and built to application-specific performance requirements identified during the collaborative project execution process led by National Bulk Equipment (NBE), in cooperation with the project owner.

(HOLLAND, MICHIGAN) -- This bulk material packaging system was engineered and built to application-specific performance requirements identified during the collaborative project execution process led by National Bulk Equipment (NBE), in cooperation with the project owner. Priority performance requirements for this bulk bag filling system included: improving operator interaction events for safety and efficiency, reducing material waste, and increasing package throughput.

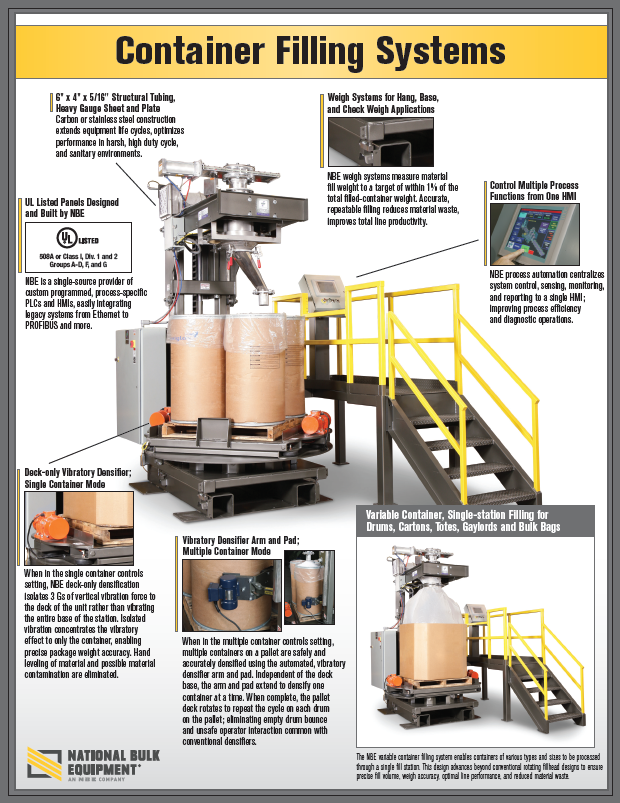

The bulk raw material supplied to this NBE bulk bag filling system is highly abrasive, fine, and dusty. The material temperature, when received at the bulk bag filler, is between 100- and 120-degrees F. To improve operator-equipment interaction this NBE bulk bag filler was designed with a cantilevered bulk bag support framework, eliminating vertical frame obstructions that impede operator accessibility. The NBE cantilevered bag support framework has a bag-load capacity of 4,000 pounds. To further improve operator safety and ergonomics, the cantilevered bulk bag support framework has NBE automatic, traversing rear bag loop hangers and an NBE automatic, traversing fillhead. The pneumatically actuated traversing rear bag loop hangers bring the rear bag loop hangers forward to well within operator reach. The operator can hang the bag loops without awkward over-reaching into equipment. A one-button operation returns the loop hangers to their rear position. The traversing fillhead also functions by pneumatic action to position the fillhead forward toward the operator. The operator can easily access the full radius of the fillspout to ensure a fully sealed spout connection to the fillhead. A one-button operation returns the fillhead back to the machine center for optimal material flow.

To eliminate costly material waste and rework associated with overfilled or underfilled bulk bags, this NBE bulk bag filler has an NBE base-weigh scale system engineered into the framework. The isolation-mount design of the scale system protects the weigh devices from damage and contamination. To ensure reliable and repeatable fill accuracy, NBE automation monitors the scale system, and based on pre-set weight specifications, adjusts upstream material supply to deliver controlled material infeed and highly accurate bag filling that is accurate to within one percent of the total filled-bag weight.

To further increase throughput performance, NBE engineered and built an application-specific bag densification system into the base of the bulk bag filling station. At pre-set intervals during the bag filling cycle, the densification base will raise to isolate the pallet and bulk bag from the conveyor deck. The densification system then initiates a vertical-motion vibratory action. This action directs 3Gs of high-speed, low-intensity vibration into the bagged material causing air to be displaced and the material to quickly settle into a dense, evenly dispersed, flat-bottomed package; increasing total process throughput rate by reducing the cycle time per filling sequence.

About NBE Holdings Company

NBE Holdings Company, based in Holland, Michigan, is a privately held corporation. The NBE Holdings Company portfolio of companies includes National Bulk Equipment, Inc. and Brawn Mixer. Employing over 200 staff members, the companies o...

+ Read more

About NBE Holdings Company

NBE Holdings Company, based in Holland, Michigan, is a privately held corporation. The NBE Holdings Company portfolio of companies includes National Bulk Equipment, Inc. and Brawn Mixer. Employing over 200 staff members, the companies of NBE Holdings Company design, engineer, manufacture, automate, and integrate bulk material handling systems for dry and liquid processing operations, and fluid mixing systems for liquid processing operations. The processing projects and systems of National Bulk Equipment and Brawn Mixer bring optimal process performance to end customers, engineering firms, integrators, and OEMs in industries including food, beverage, pharmaceutical, chemical, and ingredients processing.

Contact: Tim Wiersma, Director of Marketing

Phone: 616-399-2220

- Read less

Published by National Bulk Equipment, Inc. on Jan 19, 2022

.jpg)

.jpg)