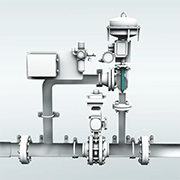

Kemutec KEK® Cone Mills Process Difficult-to-Grind Materials in Food, Chemical, and Pharmaceutical Applications

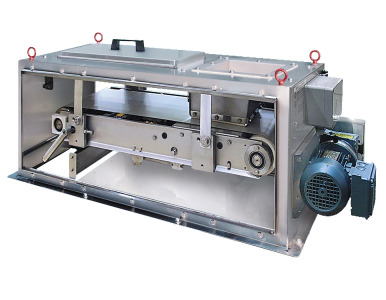

KEK® Cone Mills by Kemutec, part of the Schenck Process Group, are ideal for fatty, heat sensitive, sticky, moist and other difficult-to-grind applications in the chemical, food and pharmaceutical industries. The energy-efficient mills minimize noise, dust and heat problems typically associated with traditional mills.

KEK® Cone Mills by Kemutec, part of the Schenck Process Group, are ideal for fatty, heat sensitive, sticky, moist and other difficult-to-grind applications in the chemical, food and pharmaceutical industries. The energy-efficient mills minimize noise, dust and heat problems typically associated with traditional mills.

The KEK® Cone Mills feature a gentle, grinding action, which helps maintain a close particle size range with minimal fines generation. The residence time required to process materials is very short, resulting in negligible heat generation while drastically reducing build-up of those difficult-to-grind products.

Kemutec Kek Cone Mill for gentle grinding of bulk solids

Kemutec Kek Cone Mill for gentle grinding of bulk solids

Each unit features an ultra-hygienic design to meet critical cleanability demands inherent to the food and pharmaceutical industries. Constructed of 304 or 316 grade stainless steel, KEK® Cone Mills can be cleaned with high pressure hoses while access covers and motor shrouds are...

+ Read more

Each unit features an ultra-hygienic design to meet critical cleanability demands inherent to the food and pharmaceutical industries. Constructed of 304 or 316 grade stainless steel, KEK® Cone Mills can be cleaned with high pressure hoses while access covers and motor shrouds are sealed with easy-to-remove ‘U’ section silicone gaskets. The mills are

available in a variety of finishes, including bead blast, crack and crevice-free welds and mirror-polished surfaces.

KEK® Cone Mills are available in 7 sizes ranging from 3” to 25” (75mm to 680mm) cone diameters with process rates of up to 15 tph. The cone mills can be customized to meet individual customer needs.

“For many years, small, medium and large manufacturers in the powder and bulk processing industries throughout North America relied on Kemutec’s versatile, intermediate energy cone mill to meet their unique and challenging process requirements, frequently confirmed in our state-of-the art Test Centers,” said Karin Galloway, Executive Director of Sales – Kemutec North America.

- Read less

Published by Schenck Process on Oct 28, 2021

Schenck Process

www.schenckprocess.com

E: americas@schenckprocess.com

T 800-821-2476

816-891-9300

Address

7901 NW 107th Terrace

Kansas City, MO

64153

United States

Show map

Visit our profile