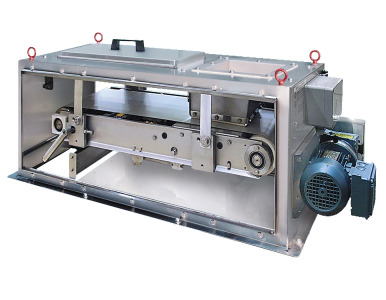

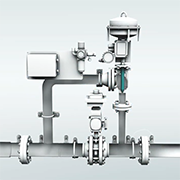

Cantilever Shaft Design for Kemutec KEK® Centrifugal Sifters Improves Powder Processing Hygiene and Ease of Operation

KEK® Centrifugal Sifters by Kemutec, part of the Schenck Process Group, feature an advanced cantilever design that greatly improves sifting efficiency in the food, pharmaceutical, chemical and environmental industries.

KEK® Centrifugal

Sifters by Kemutec, part of the Schenck Process Group, feature an advanced cantilever design that greatly improves sifting

efficiency in the food, pharmaceutical, chemical and environmental industries.

This innovative design, which has been implemented on virtually every model of

KEK® Centrifugal Sifters, features an easy to remove hygienic screen

basket and paddle screw assembly, a hinged oversized end door and bolted

flanges for dust-tight operation. The sifters also operate quietly without vibration.

The cantilevered design

improves efficiency with its clean, simple features that are operator friendly

– no tools are required for stripping down and cleaning – along with the time

saved during inspection, cleaning and maintenance. The units also contain

easily removable sifter screens for inspection and cleaning, as well as easy

access via the oversized end door, which opens in seconds. There is zero

leakage or contamination from the oversized end door.

The sifters are ideal for use

in feedstock policing, scalping, dedusting, conditioning and deagglomerating,

but can also be used in unique applications, such as de-packing, fruit

delumping, inline sieving, gas purging and explosion containment.

Kemutec Sifter for Powder and Granule Processing

Kemutec Sifter for Powder and Granule Processing

Available in white, red or blue, nylon sifting screens are built to handle the most arduous, heavy-duty applications where access for maintenance is severely limited, such as toxic and radioactive processes. Also, optional screen protectors eject incoming extraneous objects, which could dam...

+ Read more

Available in white, red or blue, nylon sifting screens are built to handle the most arduous, heavy-duty applications where access for maintenance is severely limited, such as toxic and radioactive processes. Also, optional screen protectors eject incoming extraneous objects, which could damage the sieving mesh. To further improve the sifter’s hygienic capabilities, the units can also include CIP spray facilities, inlet section access door and additional inspection doors on the sifter body.

The design is also available on KEK® models K300C, K650C, K800C and K1150C (the largest cantilevered sifter with capacities up to 80 tons per hour).

“Schenck Process has established itself as the bulk materials handling provider trusted most throughout the process industries by creating a culture of constant innovation and always looking at how our extensive product portfolio can better serve of customers,” said Karin Galloway, Executive Director of Sales – Kemutec North America. “The Kemutec KEK® Centrifugral Sifter line with unparalleled hygienic and ease-of-use standards exemplify that commitment.”

- Read less

Published by Coperion on Nov 02, 2021

Coperion

http://www.schenckprocessfpm.com

E: americas@schenckprocess.com

T 800-821-2476

816-891-9300

Address

7901 NW 107th Terrace

Kansas City, MO

64153

United States

Show map

Visit our profile