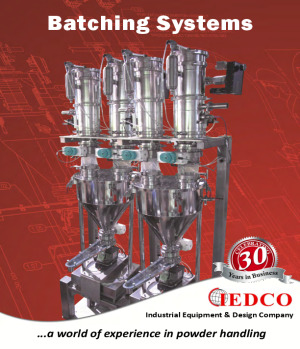

IEDCO Batching Systems

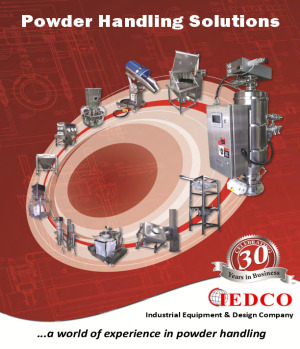

At the heart of many process systems is the need to accurately weigh out a specific quantity of one or more ingredients for further processing. This procedure is often referred to as dosing, metering, dispensing, or batching. IEDCO has 30 years of experience in this area and can design, manufacture, and integrate batching systems with extremely high accuracies.

Dust Collection & Air Pollution Control

Media, Parts, & Accessories

Bags

Feeders

Feeders

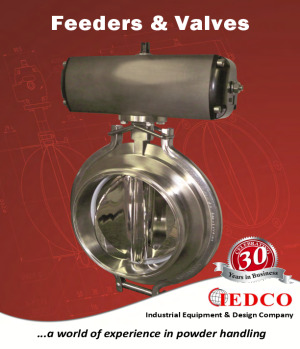

Control Valve

Dosing

Pneumatic

Rotary Valve

Vacuum

Vibratory

Instrumentation & Control

Other Instrumentation & Control

Control Panels

Material Handling & Transportation

Material Handling & Transportation

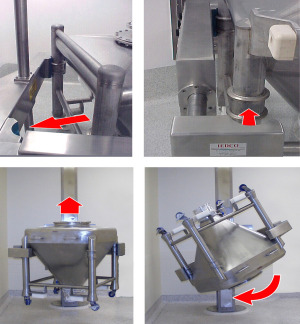

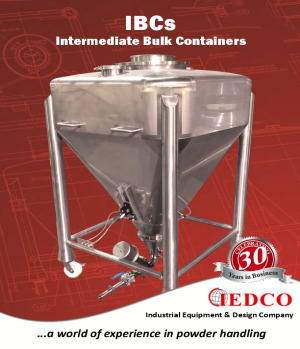

Bin (IBC) Handling Systems

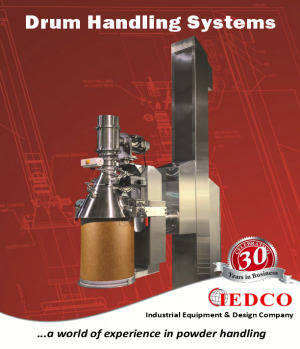

Drum Handling Equipment

Hoppers

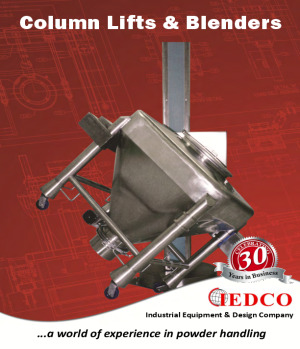

Lifts/Manipulators

Mechanical Conveying

Conveyors, Mechanical

Blending

Mixers & Blenders

Mixing & Blending Equipment

IBC

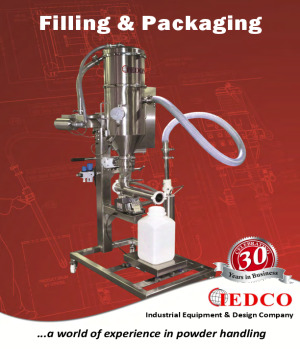

Packaging & Bagging

Equipment

Bag Dump Station

Bag Fillers

Bag Lifters

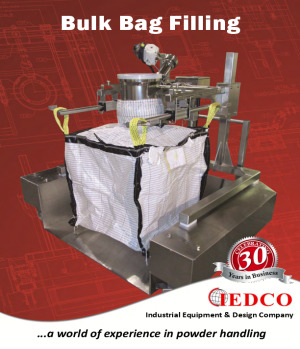

Bulk Bag Filling

Bulk Bag Handling Equipment

Bulk Bag Handling Systems

Bulk Bag Loaders

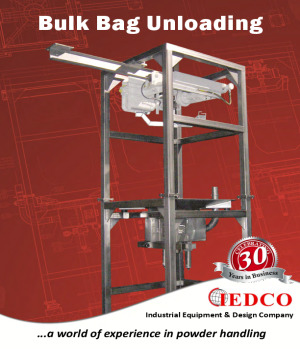

Bulk Bag Unloader

Drum Handling

Particle Enlargers & Formers

Particle Enlargers & Formers

Tablet Coaters

Tablet Presses

Pneumatic Conveying

Conveyors, Pneumatic

Complete System

Dense Phase

Dilute Phase—Combination

Dilute Phase—Vacuum

Portable

Vacuum

Size Reduction

Mills

Blending

Pneumatic

Storage

Auxiliary Equipment

Filling Systems

Lifts

Pneumatic Conveying Systems

Containers

Bins, Portable

Valves, Gates, & Airlocks

Valves, Gates, & Airlocks

Valves, Butterfly

Valves, Rotary

Valves, Sanitary

Weighing Systems & Scales

Scales

Dosing

Weighing Systems

Batching

Micro-Ingredient

Multiple Ingredient

-

IEDCO - Considerations in Designing an Excipient Dispensary

This whitepaper by IEDCO discusses considerations for designing an excipient dispensary in pharmaceutical facilities. It highlights the inefficiencies of manual dispensing and the benefits of modern, automated systems. Key considerations include the dispensary's location relative to the warehouse, types of raw ingredient containers, IBC types, weighing methods, sieving needs, batch feeders, excipient transfer methods, dedicated vs. multi-ingredient systems, small additions, and control systems. The document emphasizes the importance of understanding facility-specific variables and collaboration in the design process. IEDCO offers expertise in engineering, design, and installation of powder and tablet handling systems.

-

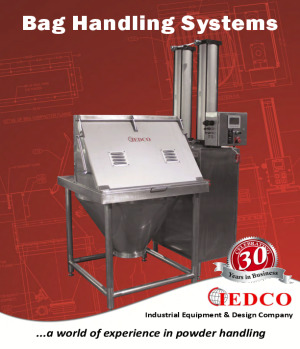

IEDCO - Considerations in Designing a Bulk Bag Unloader

This whitepaper by IEDCO outlines key considerations in designing a Bulk Bag Unloader for handling bulk powders in food, chemical, and pharmaceutical facilities. It highlights the advantages of bulk bags and the need for appropriate equipment to handle them safely and efficiently. Key design considerations include the relative location to the warehouse, methods of lifting the bulk bag (forklift, dedicated hoist, column lift), bag sizes, retaining the liner, accessing the discharge spout, ensuring reliable flow, dust control, handling partially discharged bags, transferring powder, batching, sieving, and disposing of empty bags. The document also discusses materials of construction, emphasizing the importance of stainless steel for product contact surfaces. IEDCO offers expertise in designing customized solutions for powder and tablet handling systems.

IEDCO

www.iedco.com

E: [email protected]

T: 856.728.6400

F: 856.728.6460

Address

110 American Blvd.

Suite 1

Turnersville, NJ

08012

United States

Show map

Visit our profile

Company Categories

Dust Collection & Air Pollution Control

Media, Parts, & Accessories

Bags

Feeders

Feeders

Control Valve

Dosing

Pneumatic

Rotary Valve

Vacuum

Vibratory

Instrumentation & Control

Other Instrumentation & Control

Control Panels

Material Handling & Transportation

Material Handling & Transportation

Bin (IBC) Handling Systems

Drum Handling Equipment

Hoppers

Lifts/Manipulators

Mechanical Conveying

Conveyors, Mechanical

Blending

Mixers & Blenders

Mixing & Blending Equipment

IBC

Packaging & Bagging

Equipment

Bag Dump Station

Bag Fillers

Bag Lifters

Bulk Bag Filling

Bulk Bag Handling Equipment

Bulk Bag Handling Systems

Bulk Bag Loaders

Bulk Bag Unloader

Drum Handling

Particle Enlargers & Formers

Particle Enlargers & Formers

Tablet Coaters

Tablet Presses

Pneumatic Conveying

Conveyors, Pneumatic

Complete System

Dense Phase

Dilute Phase—Combination

Dilute Phase—Vacuum

Portable

Vacuum

Size Reduction

Mills

Blending

Pneumatic

Storage

Auxiliary Equipment

Filling Systems

Lifts

Pneumatic Conveying Systems

Containers

Bins, Portable

Valves, Gates, & Airlocks

Valves, Gates, & Airlocks

Valves, Butterfly

Valves, Rotary

Valves, Sanitary

Weighing Systems & Scales

Scales

Dosing

Weighing Systems

Batching

Micro-Ingredient

Multiple Ingredient