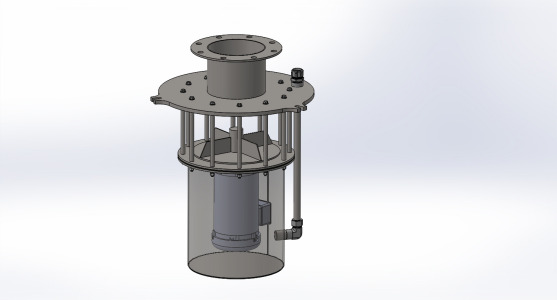

The Metalfab MHS bin activator designs incorporate the use of an internal cone-shaped baffle which is rigidly attached to the body of the bin activator by means of rugged crossmembers. The entire activator moves horizontally in response to centrifugal forces generated by the unbalanced weights of an attached vibrator.

The baffle protects the outlet from the head weight of the material above and directs material to the activator's cone-shaped walls which lead to the outlet. Vibratory forces transmit into the material as well carrying the motion from particle to particle and preventing the formation of a bridge or rat-hole. If the outlet is large enough and there is no downstream equipment to impede the flow, positive discharge is accomplished.

However, where flow is regulated by other devices, the material may become jammed or compacted at the outlet, causing a no-flow condition. The shape of the unit is irrelevant; it makes no difference whether it is dish-shaped, cone-shaped or multi-sloped. For as long as the material must travel from a larger dimension to a much smaller one at the discharge hole, convergence must take place. Vigorous vibration only serves to worsen the problem. To solve the problem, Metalfab introduced its secondary baffle design. The secondary baffle prevents jamming and compaction of the material at the outlet and allows for a constant flow upon demand.

Features/Benefits: Wide Range of Sizes: 2' to 16' diameter

Unique Dual Baffle Design: features a primary and suspended secondary baffle that delivers continuous flow of dry materials without plugging, jamming or bridging

Endless beaded Flexible Sleeve: thick, 3-ply reinforcement that will not puncture, slip or leak

Solid Steel Suspension Arms: are bolted 90° and can support up to 500,000 lbs. each to ensure the bin activator will always remain attached to the bin and cannot move off-center

Unitized Vibrator and Motor: combines the vibrator and motor in a single, sealed enclosure

Operating Characteristics: Delivers long-lasting performance with low maintenance, maximum process "uptime" and high standard quality

Construction Materials: Carbon steel, special coatings, 304SS, 316SS

- Read less