ABM Equipment Releases 9x9 Roller Mill

ABM Equipment’s new mill aims to be the highest-value mid-range, dust-tight option. It offers a number of convenient design considerations for operators to be able to change and recall settings, prevent flooding, and access the rollers.

ABM Equipment has released its new mill designed to solve problems of the other popular dust-tight roller mills. The 9”x9” rollers handle up to 66.5 lbs./min., bridging existing options at 9x6 and 9x12. The features and size of this mill is tailored toward those producing grain feed for animals, ethanol, seed oils, and some construction, plastic, and other unorganic materials.

Released at booth 3715 at CBC on Apr. 27th, the new mill had a number of new features. It had a closable flow gate to reduce the risk of flooding and both a hinged hopper and optional reversible drive in case someone forgets about the gate and floods it anyway. To simplify maintenance it is dust-tight, uses sealed bearings, includes a grate magnet to protect the rollers, and is designed to reduce roller drift. Other miscellaneous benefits are that it’s made in the USA, comes with 24/7 support, and works out-of-the-box with DSO Sentinel, ABM’s system automation software.

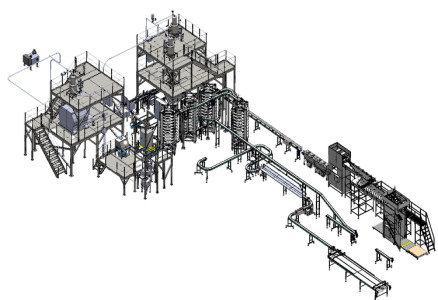

Dust-tight roller mill

Dust-tight roller mill

Though the mill at the show was a prototype and did not have them, the following features are to be added to the first units sold. First, the units will have either manual or digital roller position indicators so that operators can notate and revisit different settings. Second, an angled gravity-...

+ Read more

Though the mill at the show was a prototype and did not have them, the following features are to be added to the first units sold. First, the units will have either manual or digital roller position indicators so that operators can notate and revisit different settings. Second, an angled gravity-drop sampler will be installed for when processors are using gentle conveying methods. Those using augers should sample their grain at the final discharge because augers will affect the final result).

Involved in the development of the mill were numerous brewers, Marc Martin of Alpha King consulting, and Jim Thurman—the inventor of the Jim Boney mill. Thurman and ABM are currently collaborating on the next version of his popular 3-roller mill for smaller operations. The small 3-roller is to be released later this year and shown at the next CBC. ABM asks that millers submit feature requests to help them build the “ideal” mill.

“Some features we’ve added already exist in other mills,” said John Cassa, Co-Owner. “We just wanted to combine everything—existing features in this mill or that, solutions for problems the most popular mills have always had, and keep the price down. Our introductory price will depend on how many POs we get on release because rollers are the most expensive part and their price is volume-sensitive.”

For more information, visit ABMEquipment.com or contact John Hilgendorf at 360-558-7156 or [email protected].

- Read less

Published by ABM Equipment on May 09, 2025

ABM Equipment

abmequipment.com/

E: [email protected]

T: 503-347-8104

Address

13911 NW 3rd Ct

Vancouver, Washington

98685

United States

Show map

Visit our profile