Improvements in processing efficiency, ordering, and delivery schedules, eliminating material shortages, and reducing carrying costs are just a few of the benefits of monitoring bin levels while on-site or off-premises. Automated alerts via text or email allow for proactive actions that can add to a mill’s bottom line.

Cloud-based programs are compatible with a wide range of sensors and measurement technologies. Their versatility lends them to use with bins, as well as tanks, or silos of different shapes and sizes, storing all types of grain, feed, ingredients, fertilizer, or fuel. Replacing a manual measurement with an automated level sensor leads to:

80 GHz non-contact radar provides superior level measurement in extremely dusty conditions. Models designed for liquids perform in excessive steam, condensation, vapor, and surface foam.

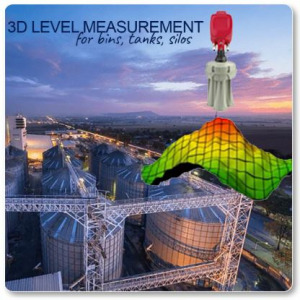

Ideal for large bins or materials that pile unevenly, this non-contact technology measures and maps multiple points on the material surface and accounts for irregularities in calculating volume. A specialized software program provides a 3D visualization of the topography and multiple bin monitoring.

Working like an automated tape measure, SmartBob sensor drops a weighted cable to a solid material surface at timed intervals. It can also measure the level of submersed solid material settled below a liquid surface.

Laser

Measuring in a tight beam, lasers are suited for feed bins and narrow vessels with lower or no-dust environments. Battery-powered models reduce wiring costs and allow for installation where power is limited or unavailable.

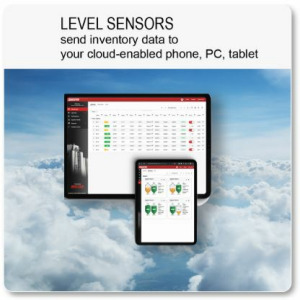

Monitor inventory on a phone, tablet, or PC

Many feed mills, grain storage facilities, and pet food plants are big in size and small on staff. Making bin inventory management available anywhere anytime enables people to be more efficient in their jobs. Today, a simple log into a website using an app or Software as a Service program puts real-time data in front of people who need it to make timely decisions.

User-friendly software platforms

As far as inventory monitoring is concerned, you can choose from software installed on your local area network (LAN) to access from a PC or a cloud-based software-as-a-service (SaaS) that is accessed from the internet on a phone, tablet, or PC.

Both are easy to work with and highly affordable. A software program installed on your local network is a one-time software purchase per location. The software accommodates up to 120 silos. Cloud-based software-as-a-service (SaaS) programs are subscriptions based on the number of bins you are monitoring. The cost is several dollars per month per bin, plus a cellular program if one is needed.

Cloud-based programs have the benefit of not requiring an IT expert to install or manage the program. Updates to the software are provided by the host company, which will also provide the necessary training and ongoing support.

Both LAN and SaaS programs offer similar features. Both have easy-to-use, graphical interfaces. Bins can be sorted by type, material, and alert status. An administrator can control who has access to the program and what information is available to them. Historical reports can be quickly downloaded for specific time periods.

Perhaps the most attractive feature of inventory management software is automated alerts. Sent via text or email, these alerts help ensure that bins or hoppers do not run empty and interfere with production. When used in tandem with purchasing, orders can be placed in a timely manner and deliveries scheduled so as not to interfere with production.

Specialized programs for feed and milling

BinMaster’s BinCloud® platform is an integrated cloud foundation for data monitoring of inventory contained in bins, tanks, and silos. It enables on-site and remote workers to work via the cloud from wherever they are. There are specialized SaaS offerings suited for grain storage operations, animal feed, and flour mills, for swine, poultry, and cattle farms.

BinView® is used in agriculture and food processing to monitor all types of solids, powders, and liquids. It is used by grain storage facilities, feed mills, pet food processors, and food and beverage plants. It is highly scalable to any number of vessels and locations. BinView® can be used with all types of level sensor technologies including non-contact radar, 3D Level Scanner, SmartBob, and laser level transmitters.

FeedView® SaaS is customized for livestock farmers raising swine, poultry, or cattle. This comprehensive feed management solution combines wireless, battery-powered laser-level sensors with simple-to-use software. It automatically measures bin levels, projects feed needs using historical consumption rates, records the use of medicated feeds, and lets farms place orders with the feed mill.

Automated alerts ensure farms know when to schedule deliveries, preventing feed shortages and eliminating late delivery charges. Allowing the feed mill access to FeedView® allows the mill and the farms to better coordinate production and delivery. When farms order the right amount of feed, they also reduce the amount of feed left over when animals are sent for processing. This reduces wasted feed, vacuuming, and disposal charges.

How Cloud computing transforms inventory

Combining cloud-based Software-as-a-Service and advanced-level sensor technology makes inventory and supply chain management easier.

- Accessibility: Information is portable and available anywhere there is internet access from a phone, tablet, or PC.

- Accurate Information: Total transparency, fewer discrepancies, and more information lead to better decisions. Know what to buy and when to order it.

- Better Control: Automation brings centralized digital control, minimal human intervention, and faster and timelier outputs.

- Cost Containment: Direct and indirect. Less overtime, automation of daily tasks, fewer inefficiencies, and no emergency or late delivery charges. Reduced disposal and vacuuming charges.

- Historical Reporting: Manage and segregate high-turn, long lead time rations, and ingredients with strict reporting requirements.

- Improved Monitoring: Real-time reports of on-hand supply, forecast when feed will run out, data is continuously updated effortlessly.

- Job Satisfaction: Less mundane work, more time for planning and problem-solving.

- Optimize Production Processes: Streamline vital communication between people and devices and get everyone on the same page.

- Process Improvements: Reduce material outages, and production stoppages due to shortages, and fewer batch processing errors lead to better quality.

- Security: Data—both past and present—is stored securely and safely.

- Simplicity: No servers, no IT department, programming updates done by host provider, no need-to-know programming to use software

- Time Savings: Less time on the phone, managing spreadsheets, fewer trips to the control room, and less time doing routine or redundant tasks.

- Vendor Managed Inventory: Ingredient suppliers can be assigned login credentials and viewing rights, so they can monitor inventory in tandem with the mill.

Three steps to specifying a system

The type, size, or number of bins you haveIf there is material in a bin, tank, or hopper— there is a sensor to measure it. Begin designing your system by creating a list of the vessels, their dimensions, the type of material stored inside, and any existing equipment installed or used on the bin like a temperature cable, ladder, or sweep. This ensures the sensor can be matched to its job. Nuances such as access to, or structure in, the vessel may also be contributing factors to sensor specification.

Also, note if the bins are grouped in any way by location. Bins grouped together physically can be addressed with wiring configurations such as daisy-chaining, which can save on wiring costs. Bins distanced further from power can be good candidates for battery-operated sensors and wireless devices. An inventory management system can be used across multiple plants or corporately for hundreds of silos.

Dryers, day bins, and fuel and chemical tanks are also excellent candidates for level sensors and inventory monitoring. They can be easily added to the same system as bins.

How frequently do you need measurements updated?Consider if you want measurements updated constantly or if readings at intervals throughout the day will suffice. Continuous-level sensors do as their name implies, they update continuously and in real-time. Readings taken at preset time intervals or on-demand may also work for your plant. Technologies such as radar update in just seconds; while the wireless laser is best for intervals every hour or 3 or 4 times a day to conserve battery life. A SmartBob can be programmed at set time intervals such as marking the beginning or end of a shift. Bobs also can take a measurement on demand with the push of a button or set it every couple of hours.

Where people see the data from a communications standpoint, determine where people need to access the data. Solutions can be designed to offer visibility from a control room, office, remote location such as corporate headquarters, or from home. SaaS offers the option to log in to view inventory anywhere you have an internet connection.

Another common device to provide convenience in the plant is a control console or digital panel meter. These can be installed for walk-up or drive-up access, indoors or outdoors. For example, a driver delivering grain should check the bin level before they start filling it. They can confirm the entire load will fit into the bin and prevent the risk of overfilling. These push-button devices are easy to use and can be used for view-only access to data on the plant floor.

- Read less